Lathe clamping tool applicable to irregular slender axial spare parts

A technology for clamping tooling and slender shafts, which is applied to metal processing machinery parts, clamping, positioning devices, etc., can solve the problems of unstable clamping and bending of shaft parts, and achieve high clamping stability and clamping The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

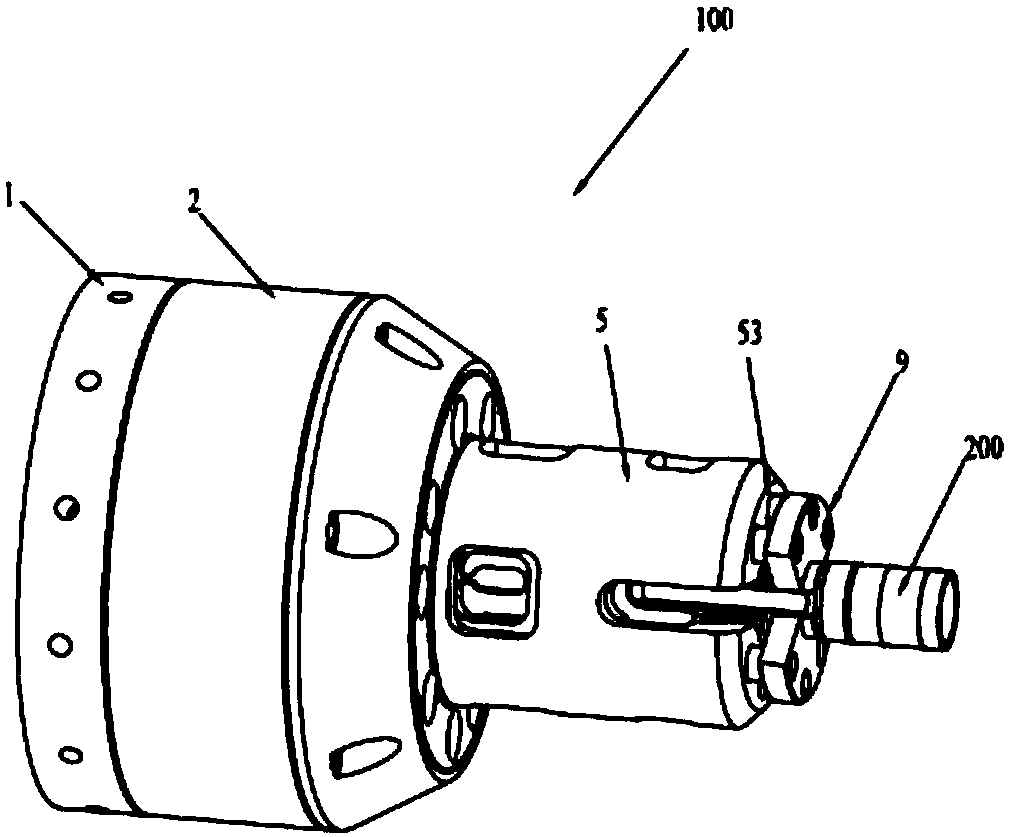

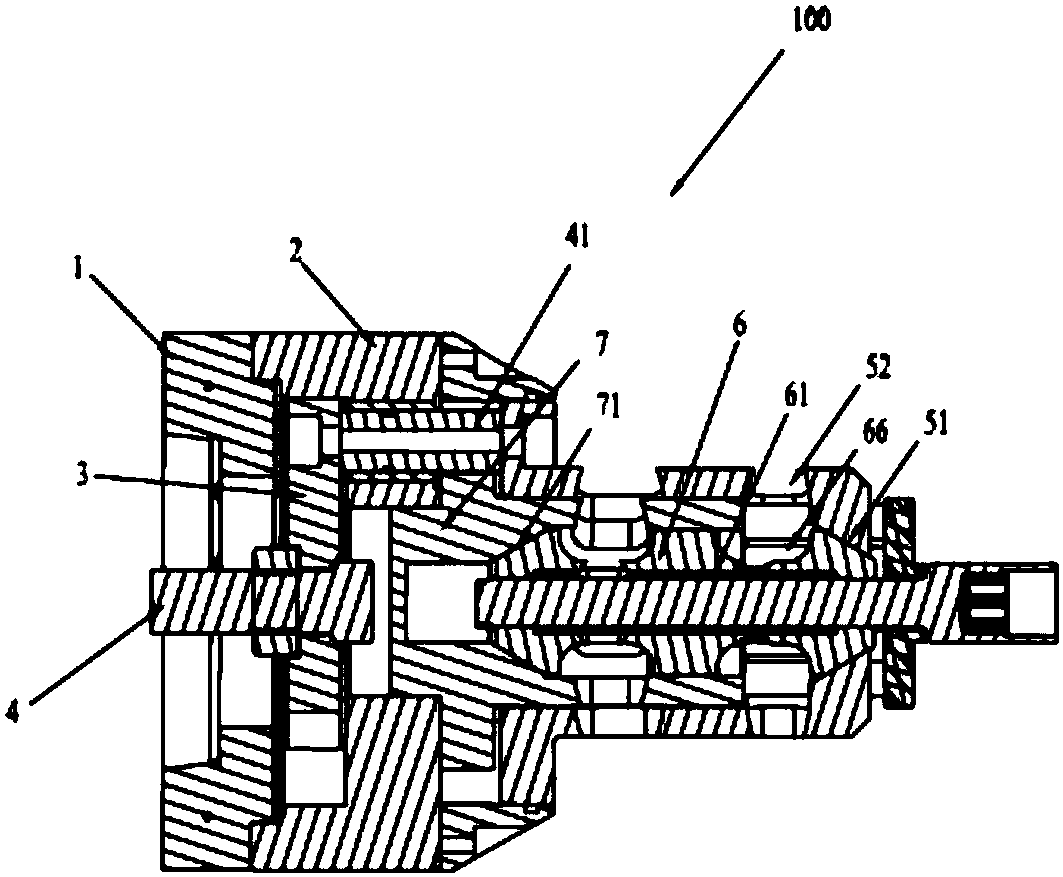

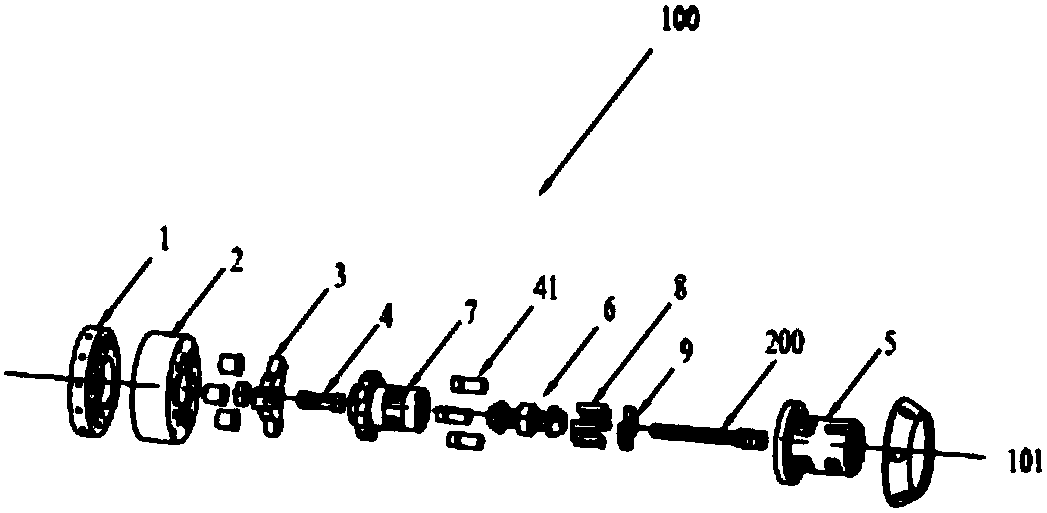

[0015] Such as Figure 1 to Figure 4 As shown, a lathe clamping tool 100 suitable for special-shaped slender shaft parts 200 includes: lathe connection plate 1, lathe rotary body 2 defining a rotary axis 101, lathe pull plate 3, pull plate fixing bolts 4, Driven pull rod 41 , clamping outer sleeve 5 , clamping inner sleeve 6 , bottom positioning sleeve 7 , positioning column 8 and axial positioning member 9 .

[0016] The lathe rotary body 2 is connected to the lathe connection plate 1; the lathe rotary body 2 rotates around the rotary axis 101; the lathe pull plate 3 is fixed to one end of the lathe pull rod by the pull plate fixing bolt 4; one end of the driven pull rod 41 is fixed to the lathe pull plate 3 The other end of the driven pull rod 41 is fixed to the clamping jacket 5; the lathe pull rod drives the clamping jacket 5 to slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com