Preparation method of bike saddle

A bicycle saddle and saddle technology, applied in bicycle saddles, bicycle accessories, transportation and packaging, etc., can solve the problems that heat cannot be dissipated quickly, people are easy to get wet, and the buttocks feel uncomfortable, etc., and achieve strong ventilation , to ensure the stability and strength, to solve the effect of discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

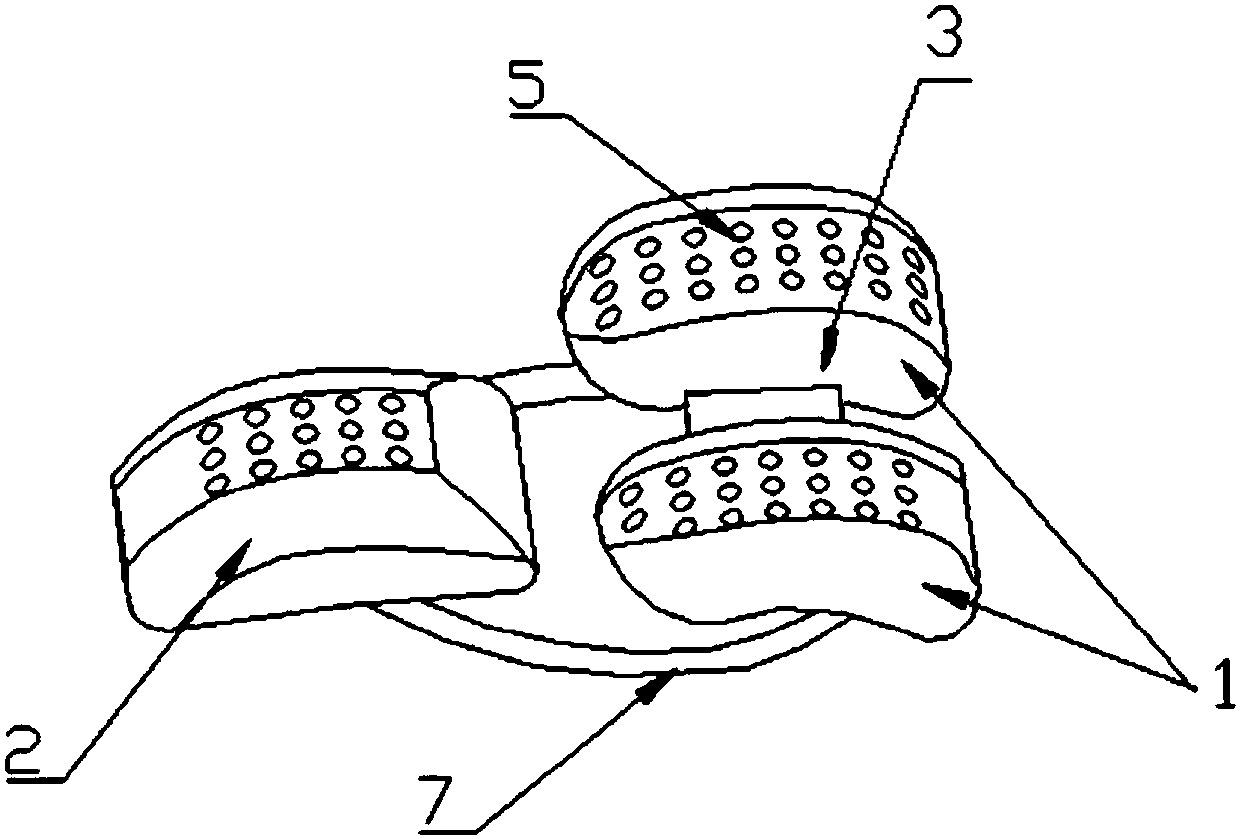

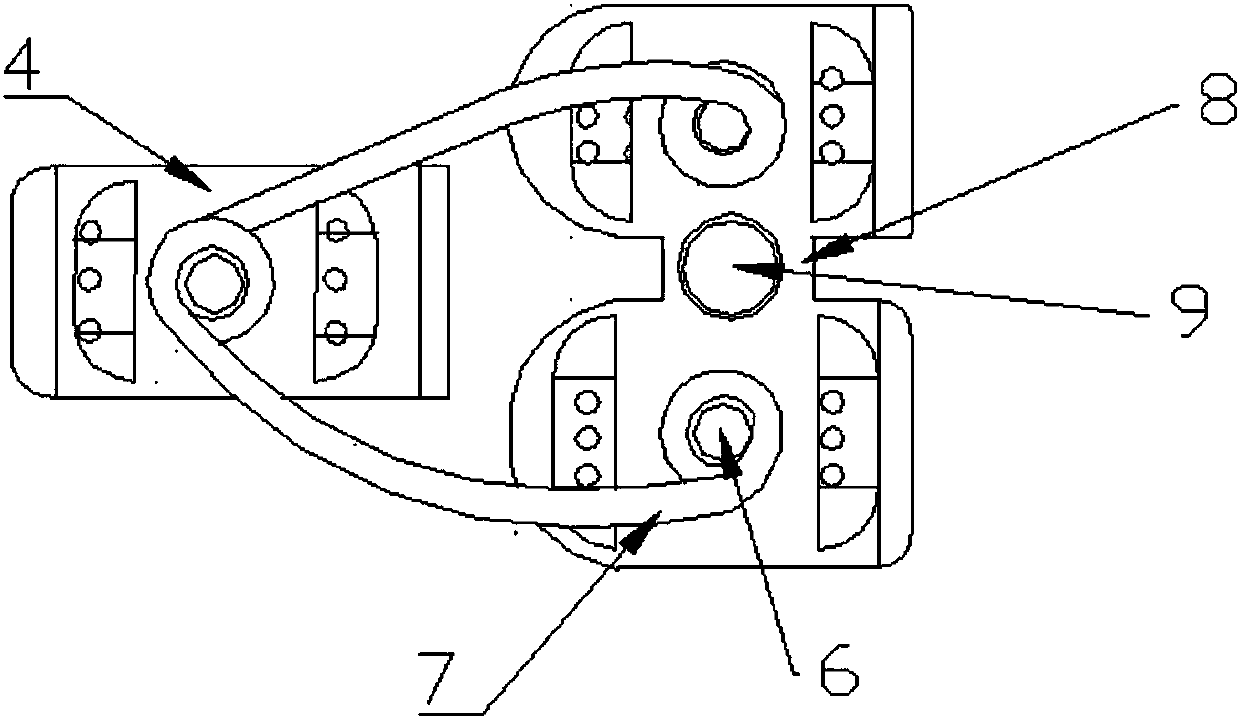

[0015] Example 1 as figure 1 , figure 2 As shown, the present invention provides a method for preparing a bicycle saddle. The saddle is composed of a split front seat body 1 and two rear seat bodies 2. The insides of the front seat body 1 and the rear seat body 2 are hollow. The cavity 3 is provided with a through hole 5 on its top surface, and a bottom plate 4 is arranged horizontally between the two sides of its bottom surface, and a guide post 6 is fixedly connected to the bottom plate 4, and a spring is wound between the guide posts 6 ; A connecting plate 8 is provided between the rear seat body 2, and an intubation tube 9 connected with the riser at the bottom of the saddle is provided on the connecting plate 8.

[0016] Further, the cross-sectional area of the bottom plate 4 is smaller than the cross-sectional area of the hollow cavity 3, and the front and rear ends of the bottom plate 4 are separated from the front and rear ends of the front seat body 1 and the re...

Embodiment 2

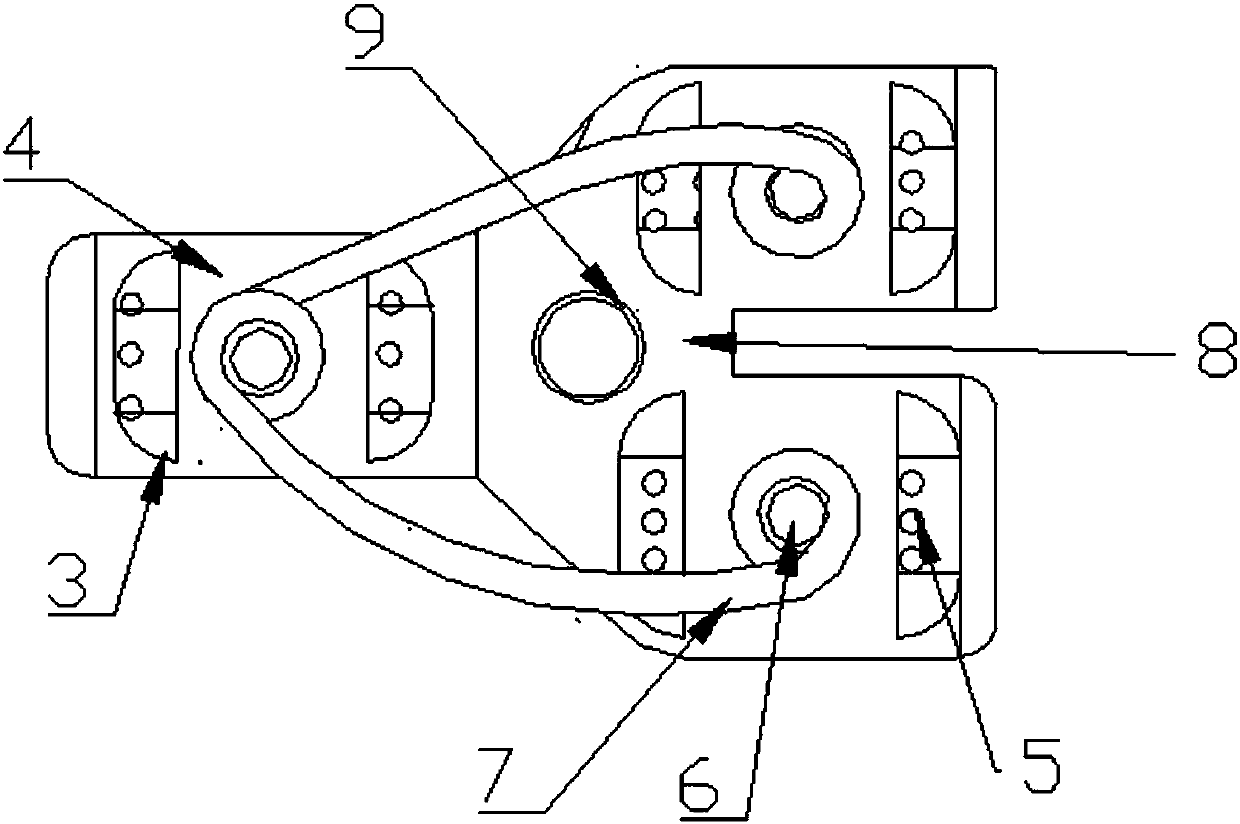

[0019] Example 2 as image 3 As shown, the present invention provides a method for preparing a bicycle saddle. The saddle is composed of a split front seat body 1 and two rear seat bodies 2. The insides of the front seat body 1 and the rear seat body 2 are hollow. The cavity 3 is provided with a through hole 5 on its top surface, and a bottom plate 4 is arranged horizontally between the two sides of its bottom surface, and a guide post 6 is fixedly connected to the bottom plate 4, and a spring is wound between the guide posts 6 ; A connecting plate 8 is provided between the front seat body 1 and the rear seat body 2, and an intubation tube 9 connected with the riser at the bottom of the saddle is provided on the connecting plate 8 .

[0020] Further, the cross-sectional area of the bottom plate 4 is smaller than the cross-sectional area of the hollow cavity 3, and the front and rear ends of the bottom plate 4 are separated from the front and rear ends of the front seat bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com