Connecting structure of assembling type prefabricated columns and construction method thereof

A technology for connecting structures and construction methods, applied in the direction of columns, piers, pillars, etc., to achieve the effect of strengthening the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

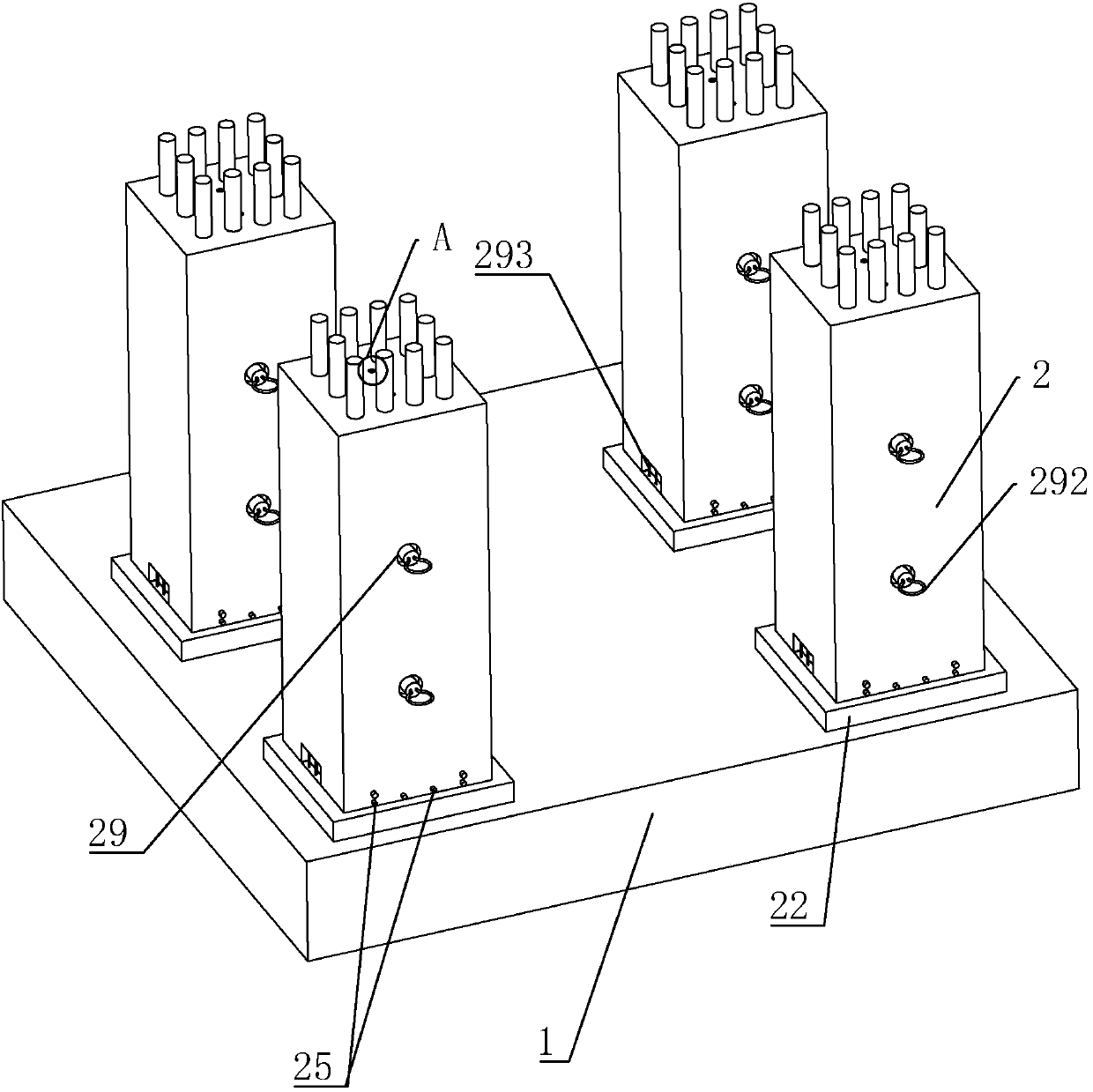

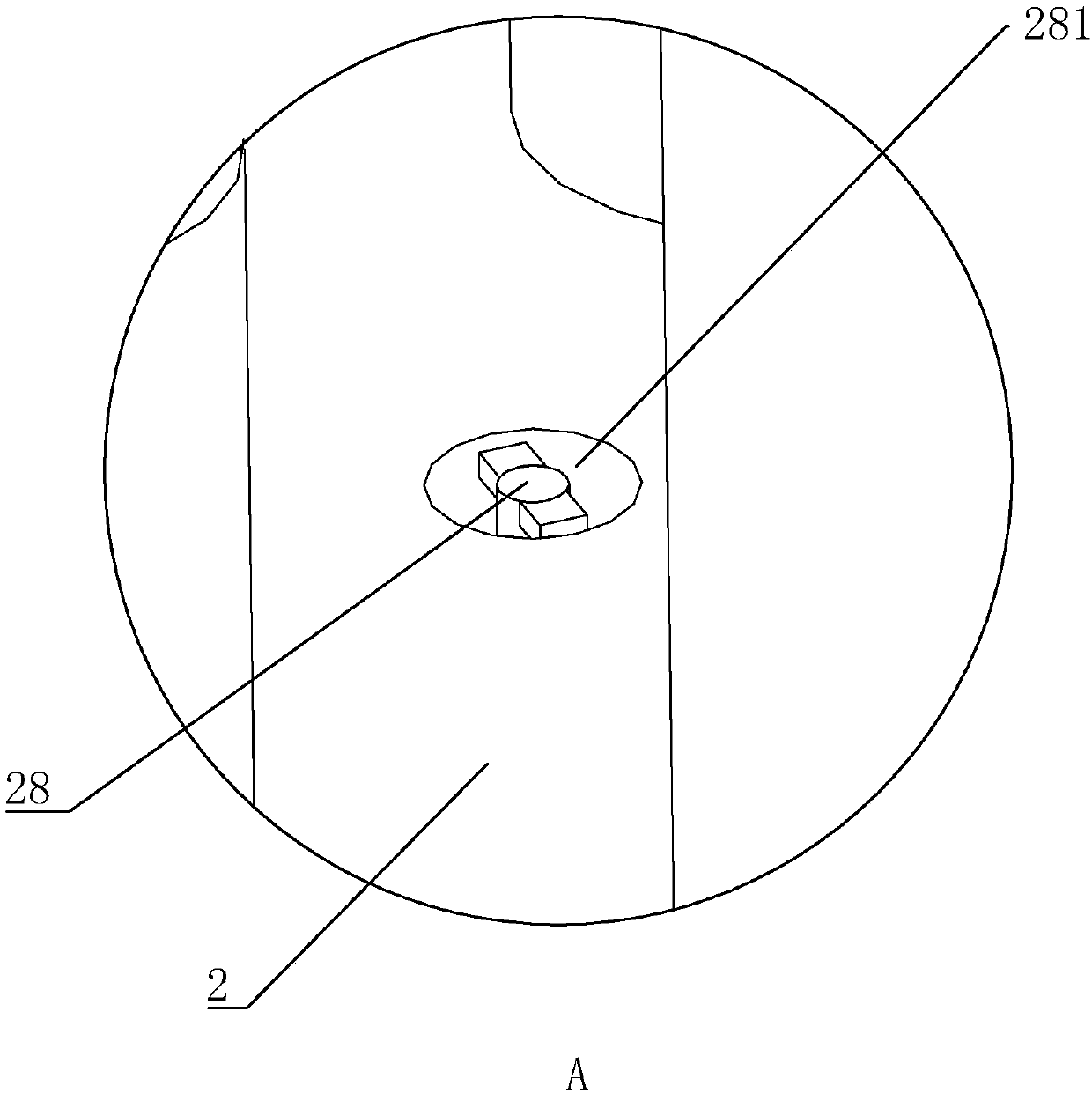

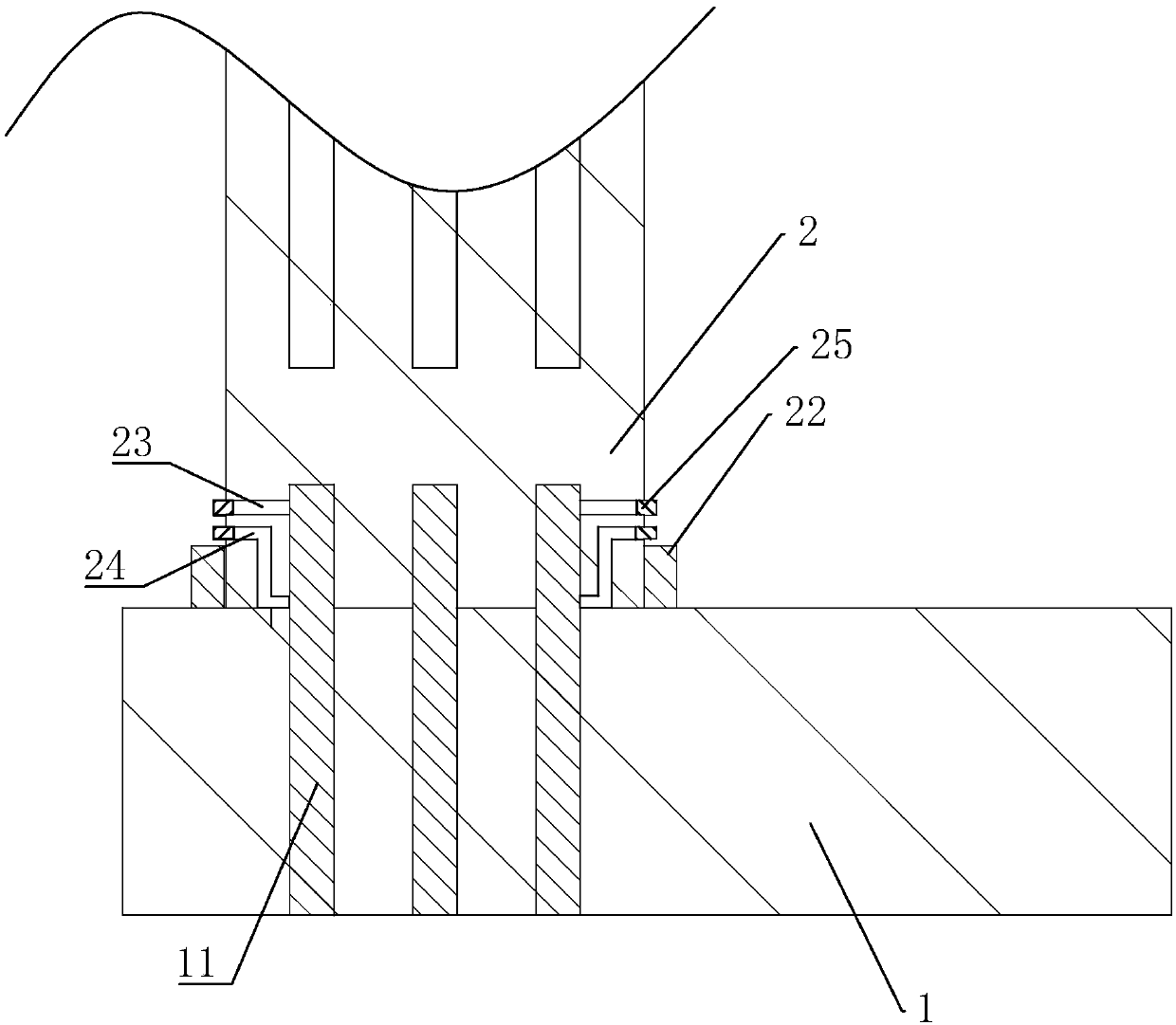

[0045] A connection structure of assembled prefabricated columns, such as figure 1 , including several prefabricated columns 2 perpendicular to the prefabricated base 1 arranged on the prefabricated base 1, the position where the prefabricated base 1 and the prefabricated columns 2 are connected is provided with a number of reinforcement bars 11 protruding from the prefabricated base 1, and the reinforcement 11 runs through the prefabricated base 1 (such as Figure 4 ), the prefabricated column 2 is provided with a prefabricated hole 21 for the insertion of the steel bar 11 (such as Figure 5 ), to facilitate the connection of steel bars 11 and prefabricated columns 2, such as image 3At this time, the outer wall of the lower end of the prefabricated column 2 is provided with a grouting hole 23 communicating with the prefabricated hole 21 and a number of grouting holes 24 extending from the bottom of the prefabricated column 2 to the lower end of the prefabricated hole 21. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com