Energy-saving biomass burning furnace

A technology of biomass and stoves, which is applied to the combustion air/flue gas circulation of furnaces, household appliances, household stoves/stoves, etc., which can solve the problem of low utilization rate of heat energy, achieve full contact and improve heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

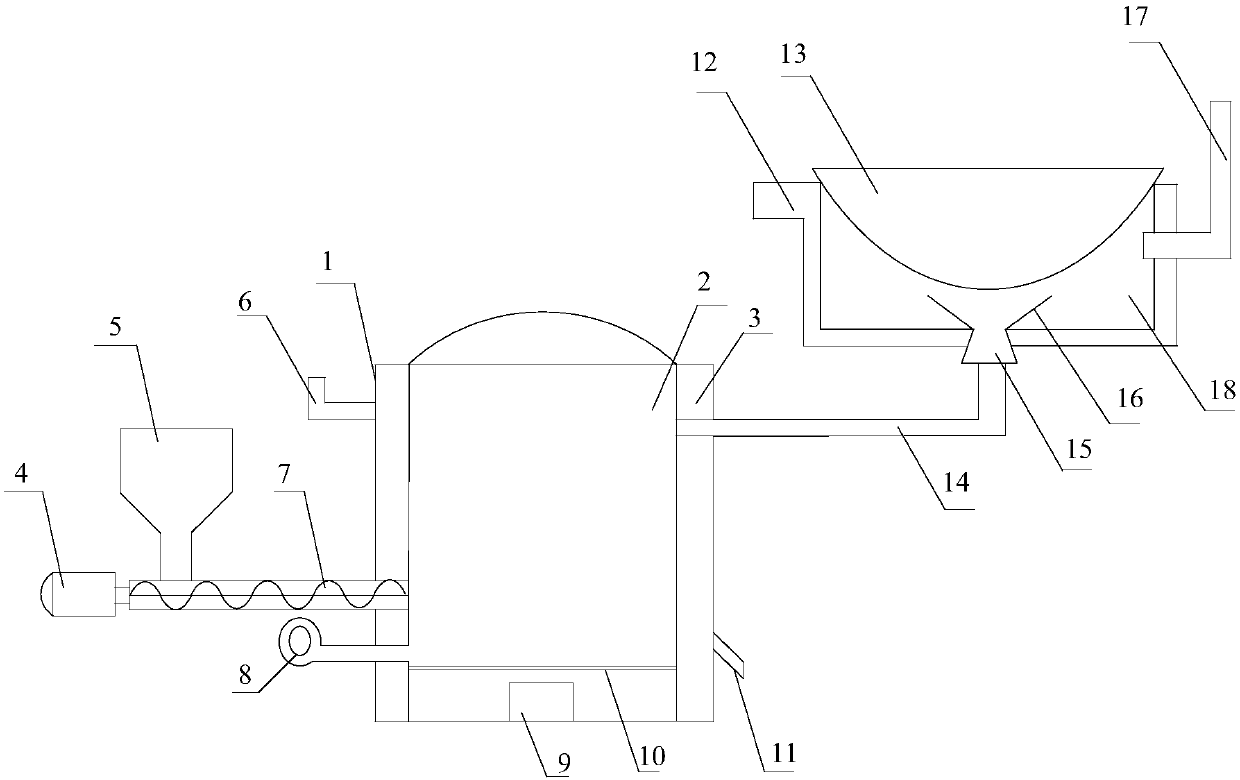

[0016] Such as figure 1 As shown, the biomass energy-saving combustion stove of the present invention includes a furnace 2, and a tank body 1 arranged outside the furnace 2; a cavity 3 is formed between the tank body 1 and the furnace 2, and the tank body 1 is provided with a Water port 6 and water outlet 11; inject clear water into the cavity 3 from the water inlet 6, when the biomass burns in the furnace 2, the heat is transferred to the clear water in the cavity 3, thereby heating the clear water, and the heated clear water can be Released from the water outlet 11, it is used as domestic water for people; in this way, the heat energy generated by the combustion device can be fully utilized to avoid waste of heat energy.

[0017] In order to better add biomass into the furnace 2 , the combustion device also includes a feeding device communicated with the furnace 2 . Specifically, the feeding device includes a screw feed tube 7 communicated with the furnace 2, a motor 4 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com