Liquid nitrogen tank

A liquid nitrogen tank and tank body technology, applied in the field of liquid nitrogen tanks, can solve the problems of insecurity, waste, inconvenience in use, etc., and achieve the effects of safe use, good usage, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

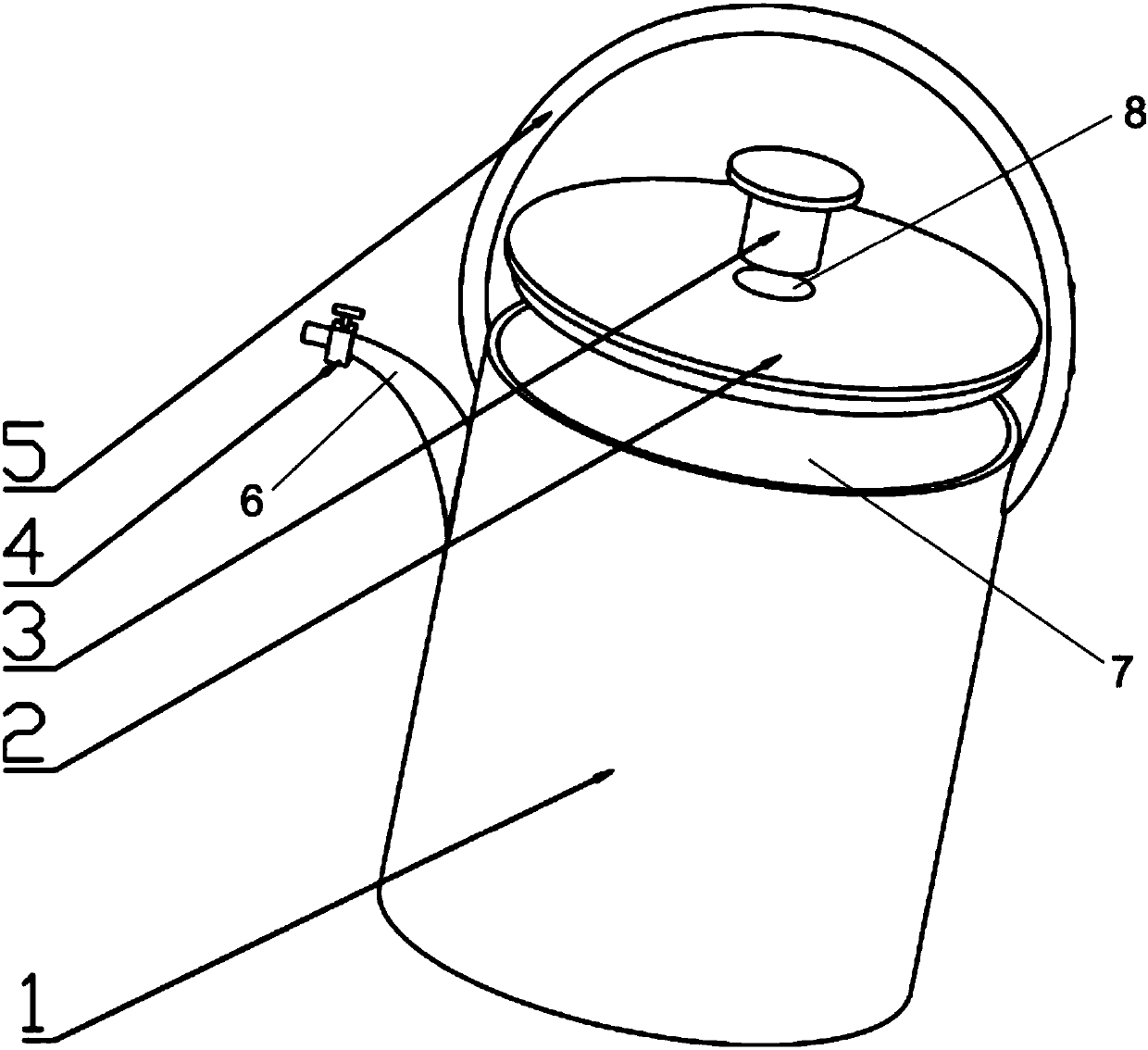

[0011] like figure 1 Among them, a liquid nitrogen tank includes a tank body 1 with an open upper end, an outlet pipe 6 connected to the tank body 1, a sealing valve 4 is installed at the outlet end of the outlet pipe 6, and a first sealing valve is installed at the opening 7 of the tank body 1. Cover 2, the first sealing cover 2 is provided with a sealing cover opening 8, the second sealing cover 3 is installed on the sealing cover opening 8, the size of the second sealing cover 3 is smaller than the size of the first sealing cover 2, and the tank body 1 is also Handle 5 is installed.

[0012] The sealing valve 4 is wrapped with an antifreeze layer, and the antifreeze layer is a cotton cloth layer.

[0013] The handle 5 is wrapped with an antifreeze layer, and the antifreeze layer is a cotton cloth layer.

[0014] The first sealing cover 2 and the second sealing cover 3 are circular covers, the diameter of the second sealing cover 3 is 4-6 cm, and the second sealing cover 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com