Furrow opener of wheat sowing machine and furrow opener assembly

A seeder and ditch opener technology, which is applied in the direction of digging/covering ditches, planting methods, applications, etc., can solve the problems of burning seeds, etc., and achieve the effects of high operating efficiency, wide application range, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

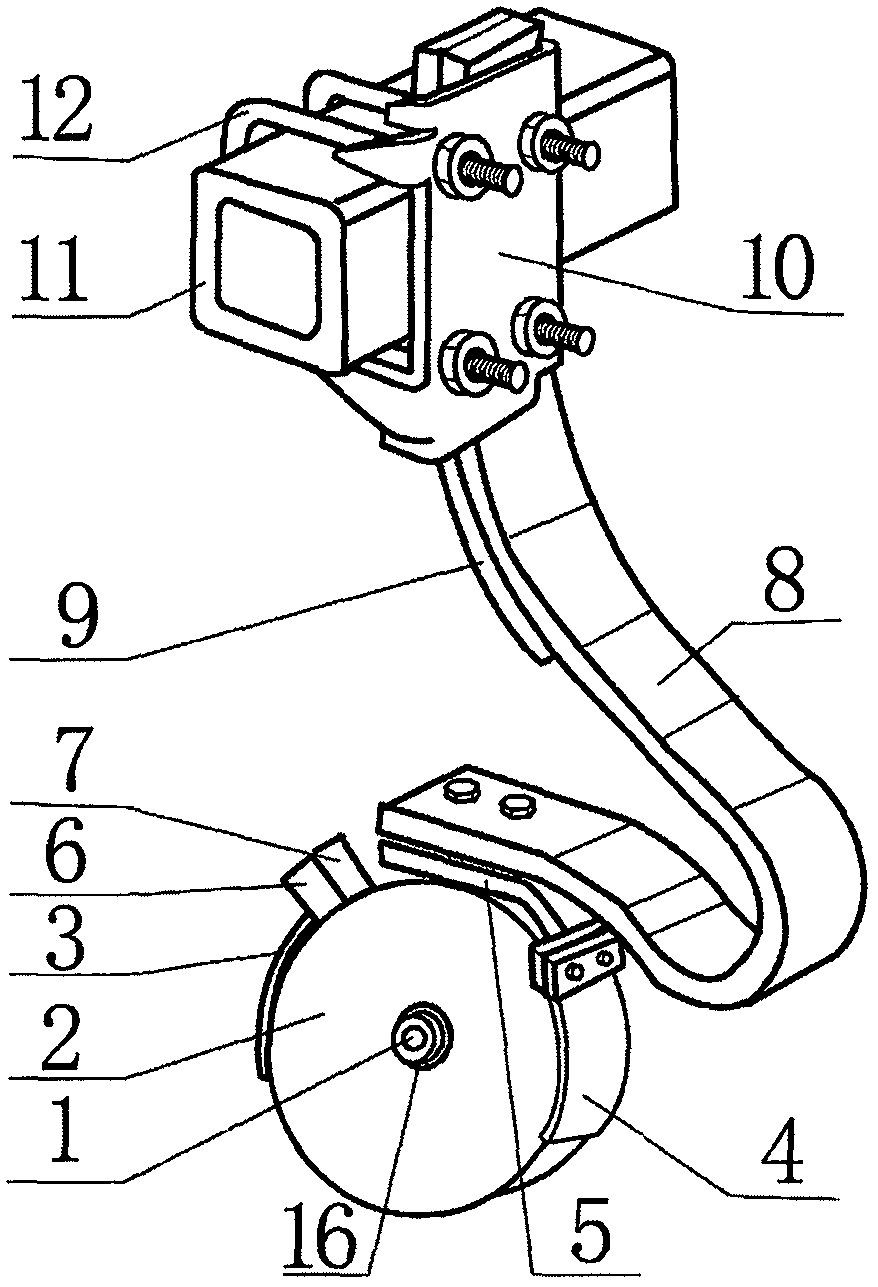

no. 1 example

[0035] The upper part of the described seed feeding pipe 6 is a single pipe, and its lower part is two thin pipes that are thinner than its upper single pipe after bifurcation, so that the two sides of the fertilizer are seeds to be cultivated separately, so that the two sides of the front fertilizer and the back are double seeded. .

no. 2 example

[0037] The upper part of the described seed feeding pipe 6 is a single pipe, and the lower part is that the single pipe is half-opened and split a certain distance, and the gap part after the splitting is repaired and welded with a herringbone shape with a steel sheet, so that the two sides of the fertilizer are seeds to be cultivated separately, Do double planting on both sides of the front and rear.

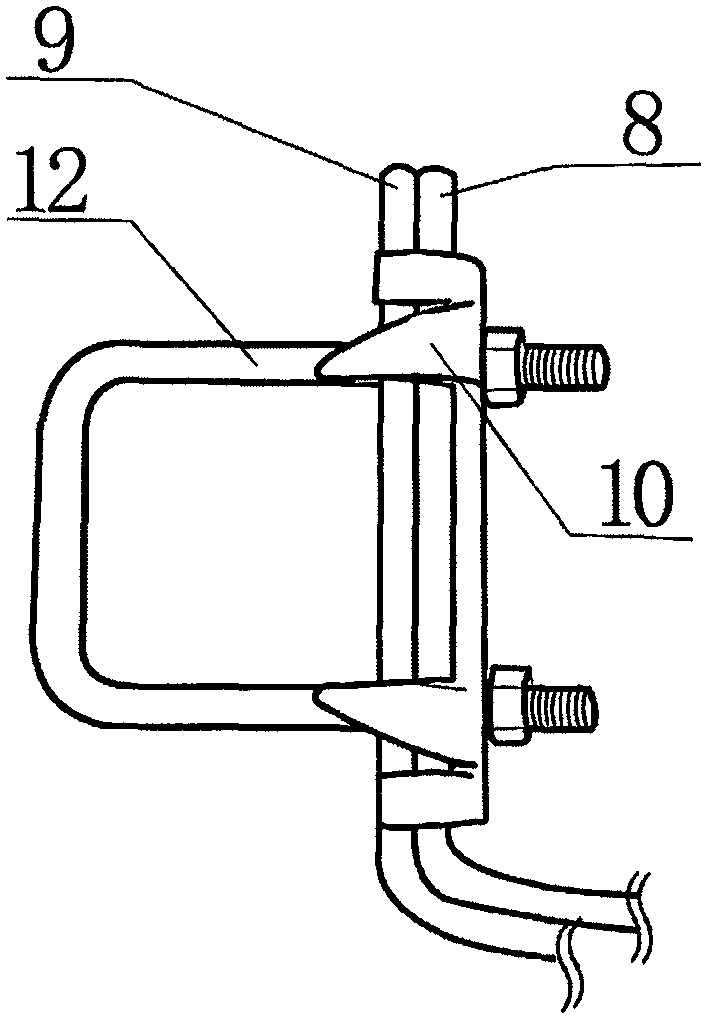

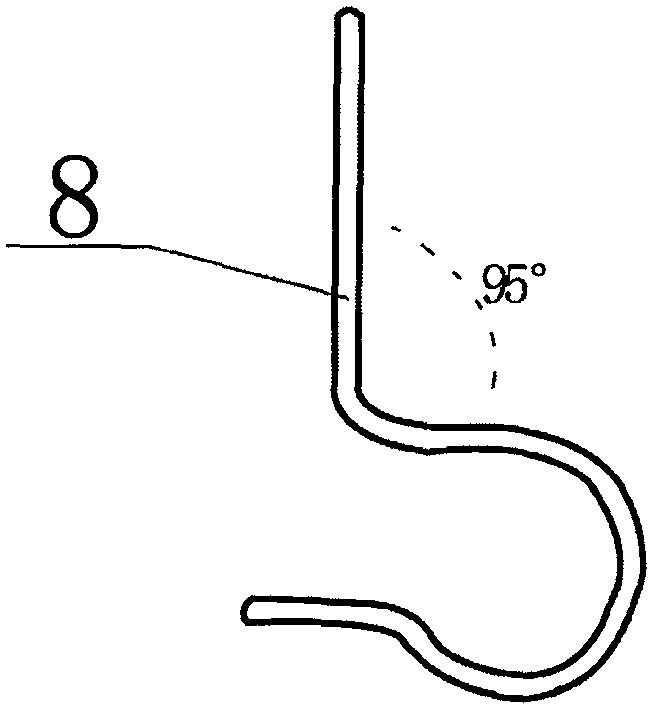

[0038] The first embodiment of the spring plate 8:

[0039] like image 3 As shown, the vertical bending angle of the spring plate 8 is 70 degrees to 100 degrees.

[0040] The optimum angle of its vertical bend is 95 degrees.

[0041] The first embodiment of the spring plate 8:

[0042] like Figure 4 As shown, the angle of the vertical bending portion of the spring plate 8 is between 100 degrees and 140 degrees.

[0043] The optimum angle of its vertical bend is 95 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com