Dust collector

A vacuum cleaner and dust collection technology, applied in the direction of vacuum cleaners, suction filters, suction nozzles, etc., can solve the problems of insufficient lightness of operation, operation fatigue, inconvenient movement, etc., achieve flexible and light operation, reduce grip force, and facilitate heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

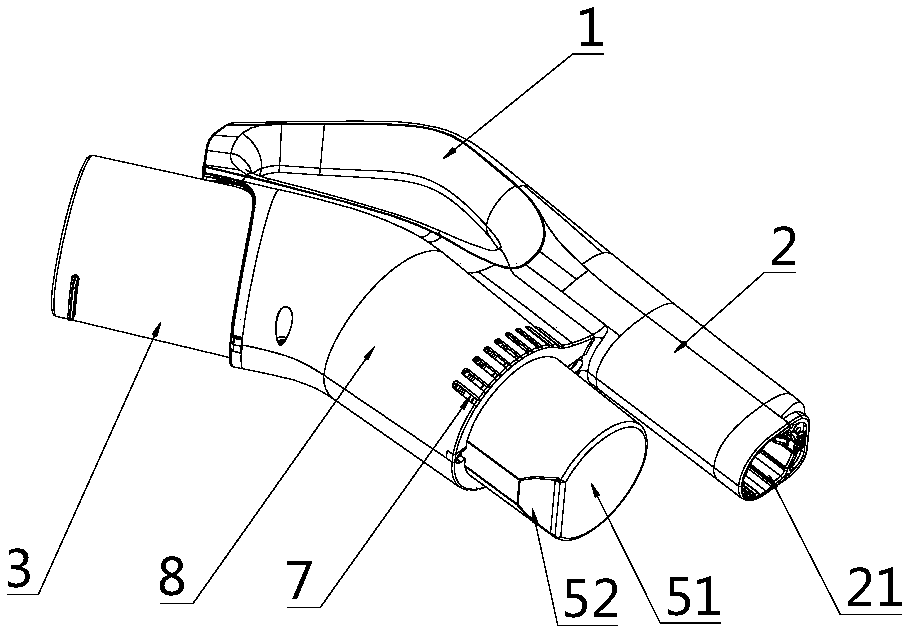

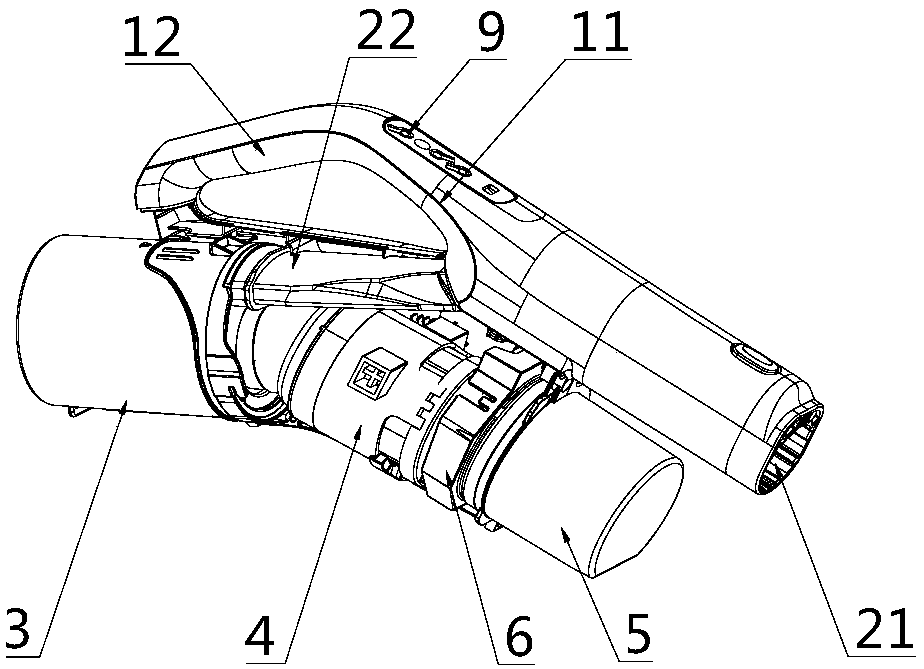

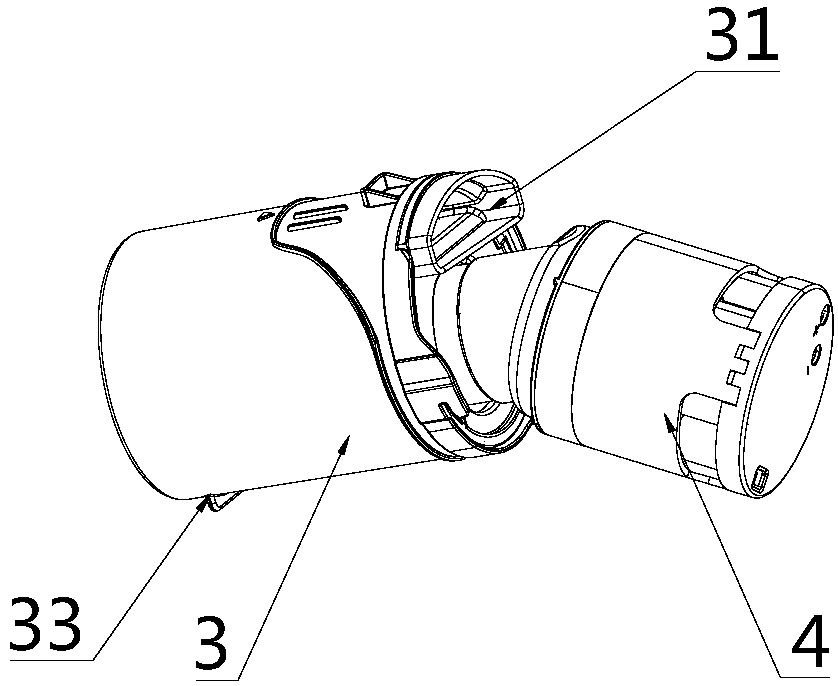

[0027] The invention provides a vacuum cleaner, such as Figure 1 to Figure 4 As mentioned above, it includes a handle assembly and a dust collection assembly. The handle assembly includes a handle 1 and a connecting pipe 2 connected to the front end of the handle 1. The front end of the connecting pipe 2 is provided with an air inlet 21, and the dust collection assembly is connected to the handle assembly. , the dust collection assembly includes a dustbin 3, a motor 4 and a battery 5, a control circuit board 6 is arranged between the motor 4 and the battery 5, the battery 5 is electrically connected to the motor 4 through the control circuit board 6, and the dustbin 3 has an air inlet 31 and the air outlet 32, the dustbin 3, the motor 4 and the battery 5 are arranged sequentially from the back to the front, the air inlet 31 of the dustbin 3 communicates with the rear end of the connecting pipe 2, and the dustbin 3 is positioned at the rear of the connecting pipe 2, The front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com