Full-automatic pipe contraction machine

A tube shrinking machine, fully automatic technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problem of increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

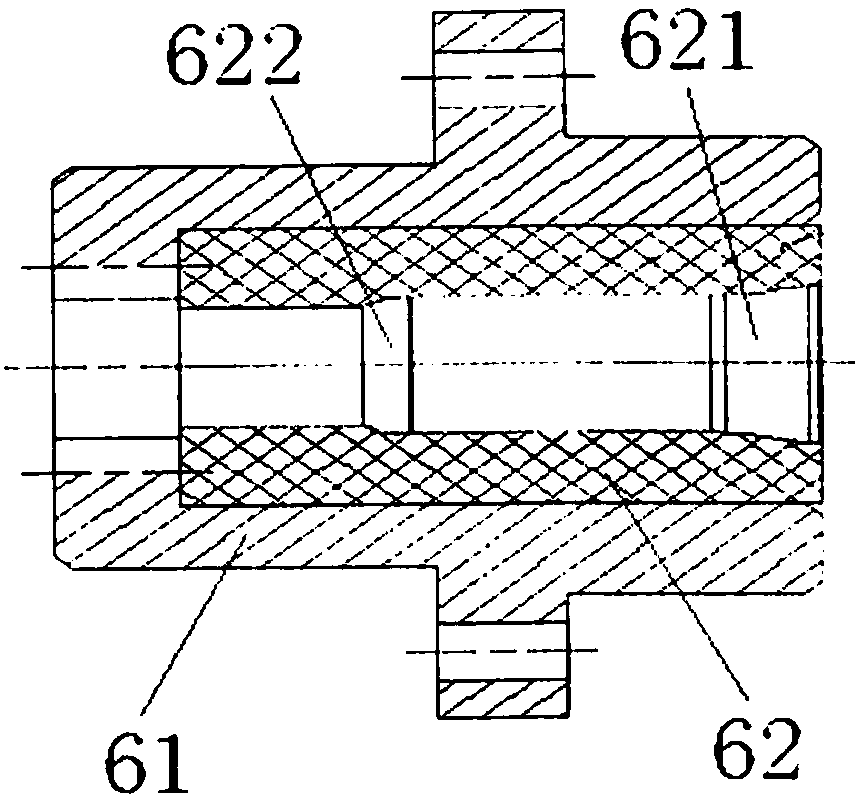

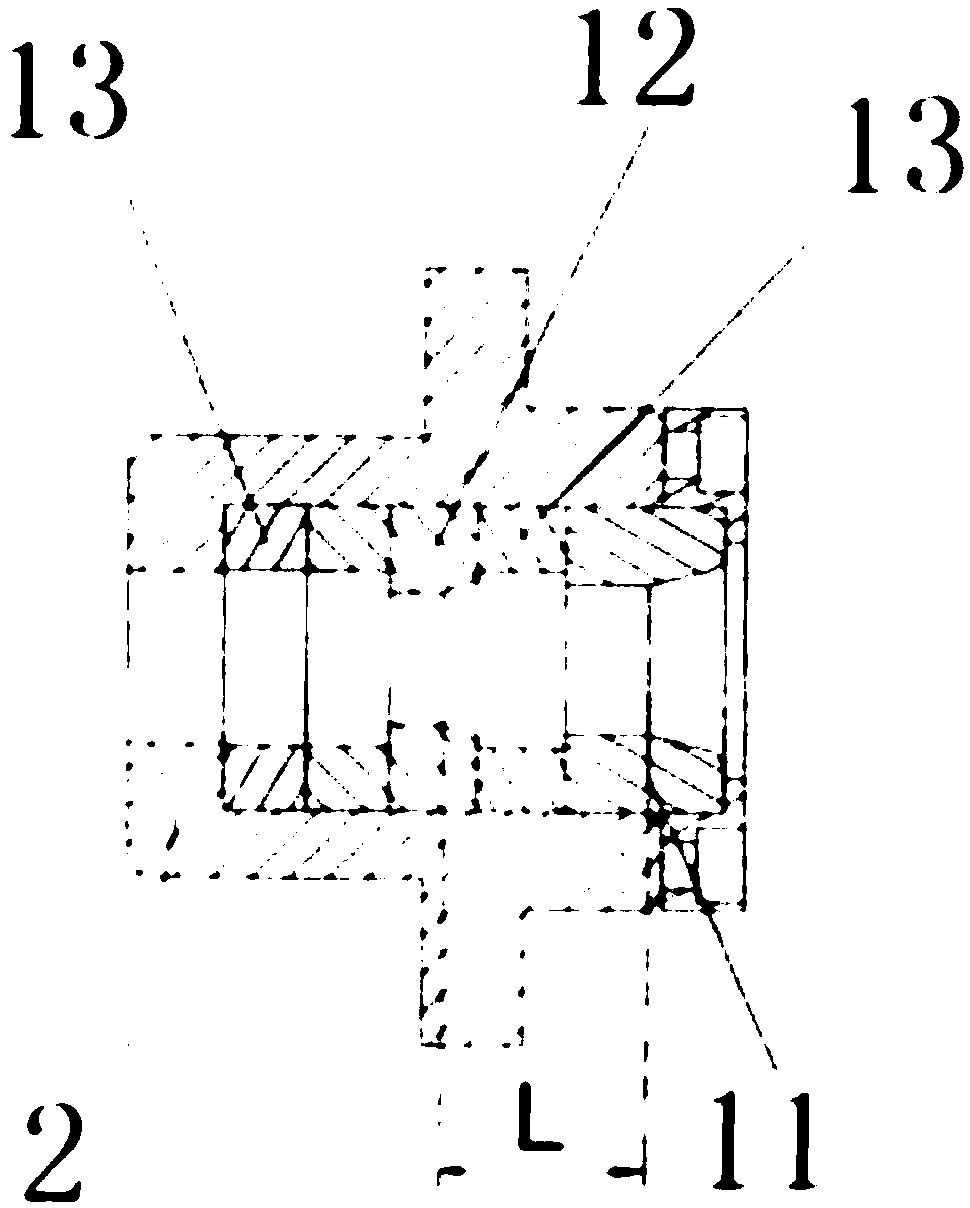

[0017] combine figure 2 and image 3 , as described in detail below:

[0018] A fully automatic tube shrinking machine, comprising a tube shrinking mold set 1, a mold cover 2 clamping and fixing the tube shrinking mold set 1, and a positioning rod for passing through a sleeve pipe, the positioning rod is located at the center of the shrinking tube mold set 1 In the hole, and one end is fixed on the mold cover 2, the shrinking die set 1 has a shrinking die 11 for tightening the mouth of the pipe fitting, and a closing die 12 for tightening the middle part of the pipe fitting, the shrinking die 11 and the closing die 12 are Independent molding, since the shrinking die and closing die 12 are formed independently, the shrinking distance L between the shrinking die and the closing die can be adjusted freely, thereby freely adjusting the distance between the shrinking pipe at the mouth of the pipe fitting and the shrinking pipe in the middle of the pipe fitting .

[0019] In ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com