Double aluminum suppository cooling device

A technology for cooling equipment and suppositories, which is applied in the field of cooling equipment for double aluminum suppositories, which can solve the problems such as the inability to adjust the distance between the medicine belts, and achieve the effects of preventing the medicine belt from tearing, prolonging the length and time of cooling, and enhancing the applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

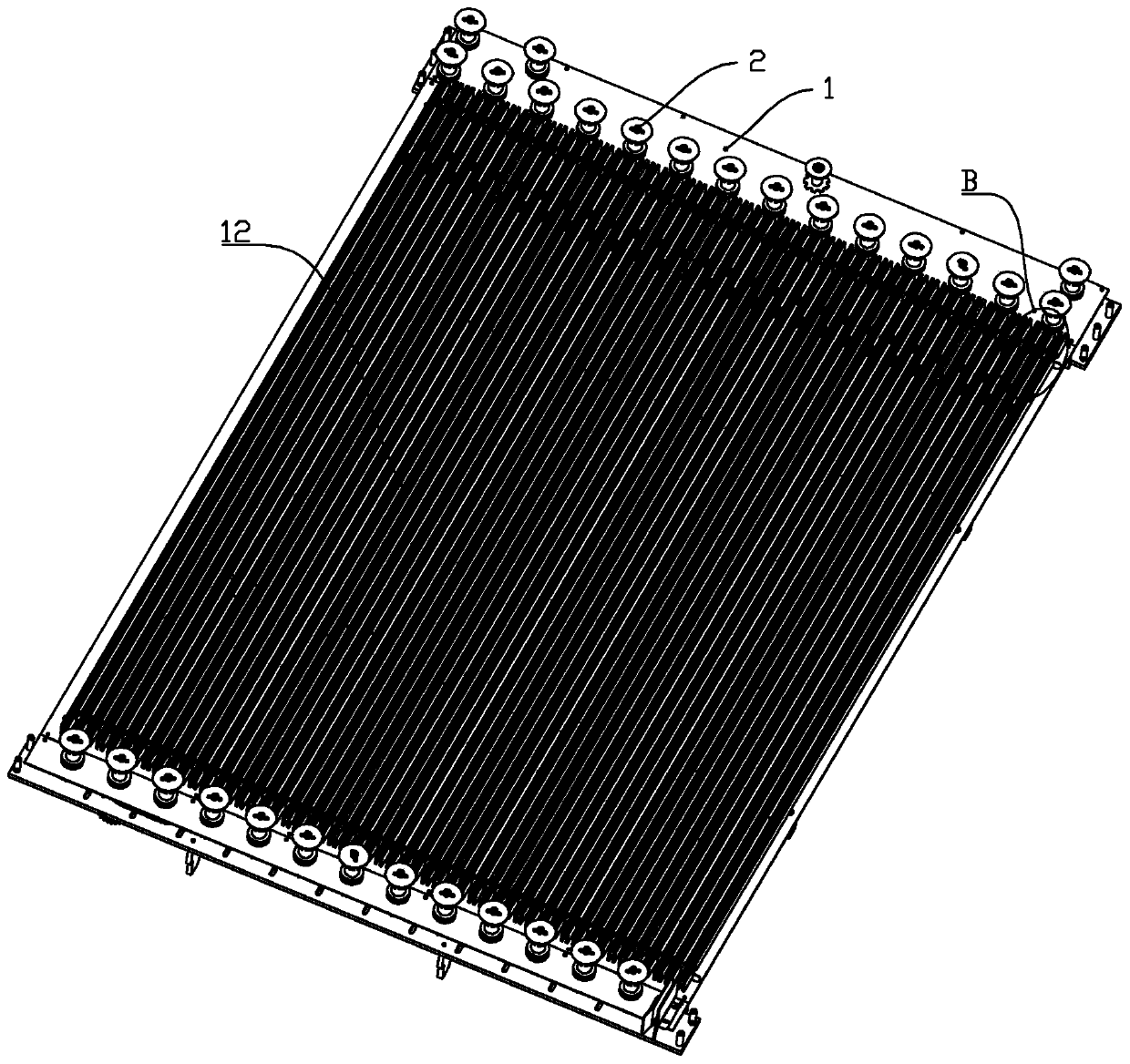

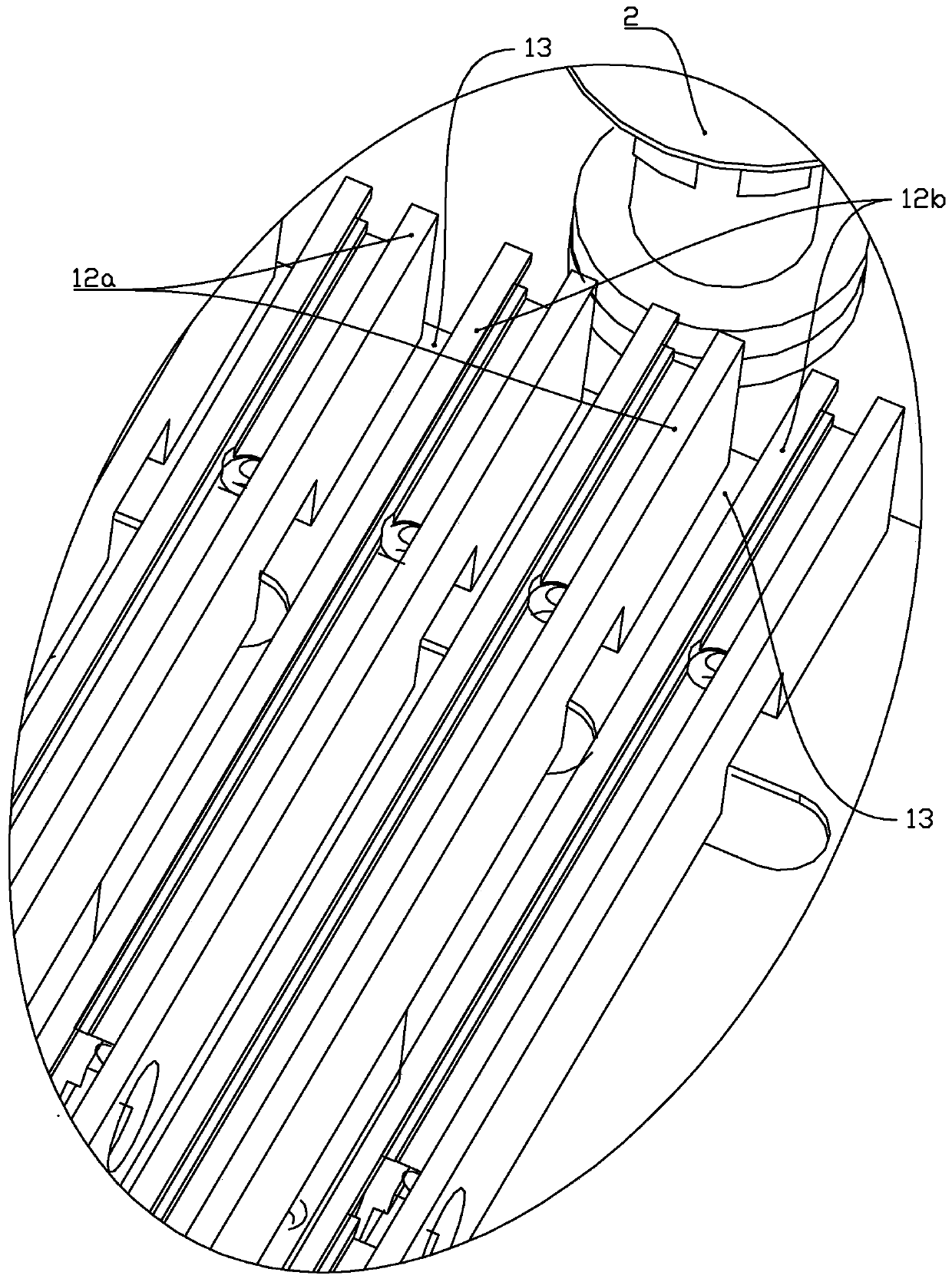

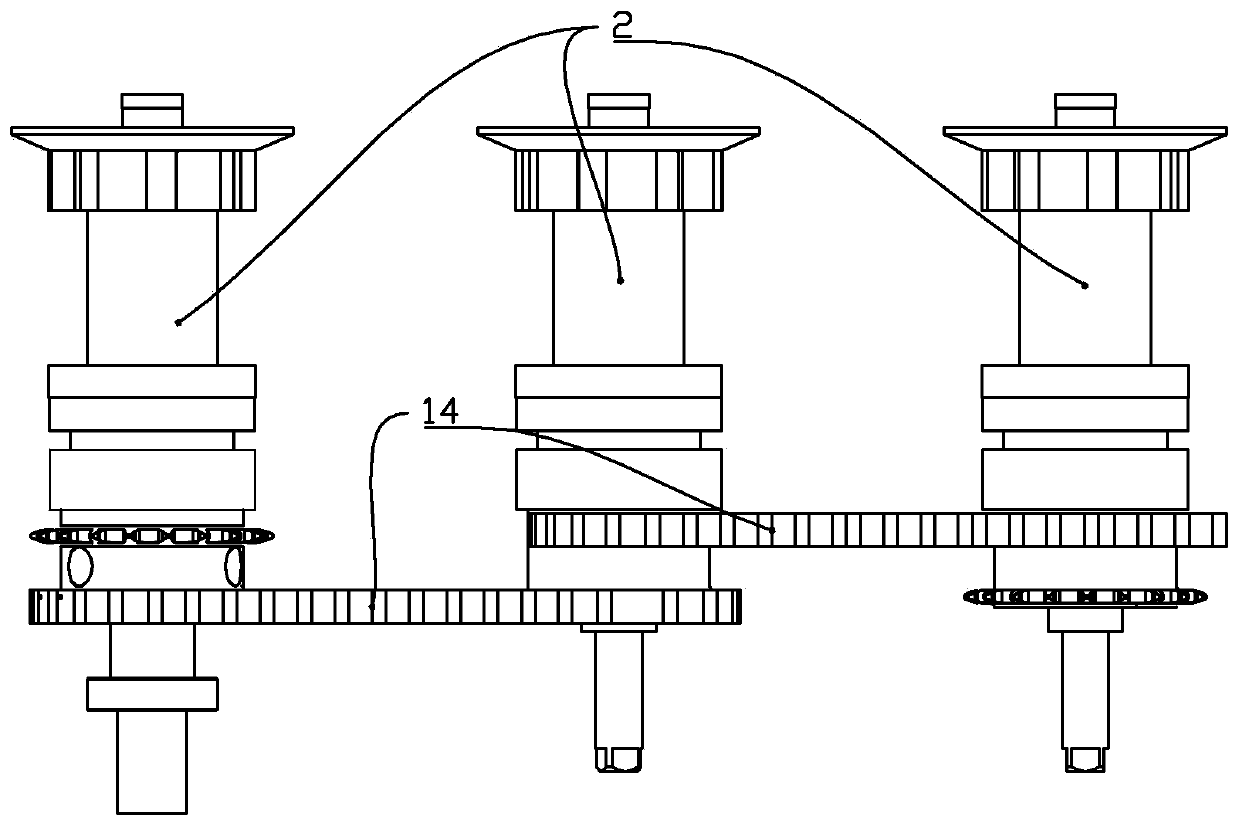

[0031] Attached below Figure 1-11 The specific implementation manner of the present invention will be described in further detail.

[0032] A double aluminum suppository cooling device.

[0033] Such as figure 1 with figure 2 As shown, at least four cooling plates 12 are arranged in the cooling box 1, and feeding passages 13 for suppository transmission are arranged between adjacent cooling plates 12, and adjustment wheels 2 are arranged at both ends of the cooling plates 12, When the suppository reaches one end of the cooling plate 12, it rotates around the adjusting wheel 2 and points to another group of feeding channels 13. Such a reciprocating design increases the cooling time and length, thereby ensuring the uniformity of cooling. The adjusting wheel 2 The upper and lower runners are adsorbed together by magnetic coupling. When the torque on the adjustment runner 2 is too large, the upper and lower runners can slip freely, which effectively prevents the drug belt fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com