Precise electric screwdriver

An electric screwdriver and screwdriver head technology, applied in the field of screwdrivers, can solve the problems of long overall length of the screwdriver, small torque of the composite mechanism, long empty travel of the output shaft, etc., to improve driving efficiency, reduce friction, and shorten the overall length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above objects, features and beneficial effects of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

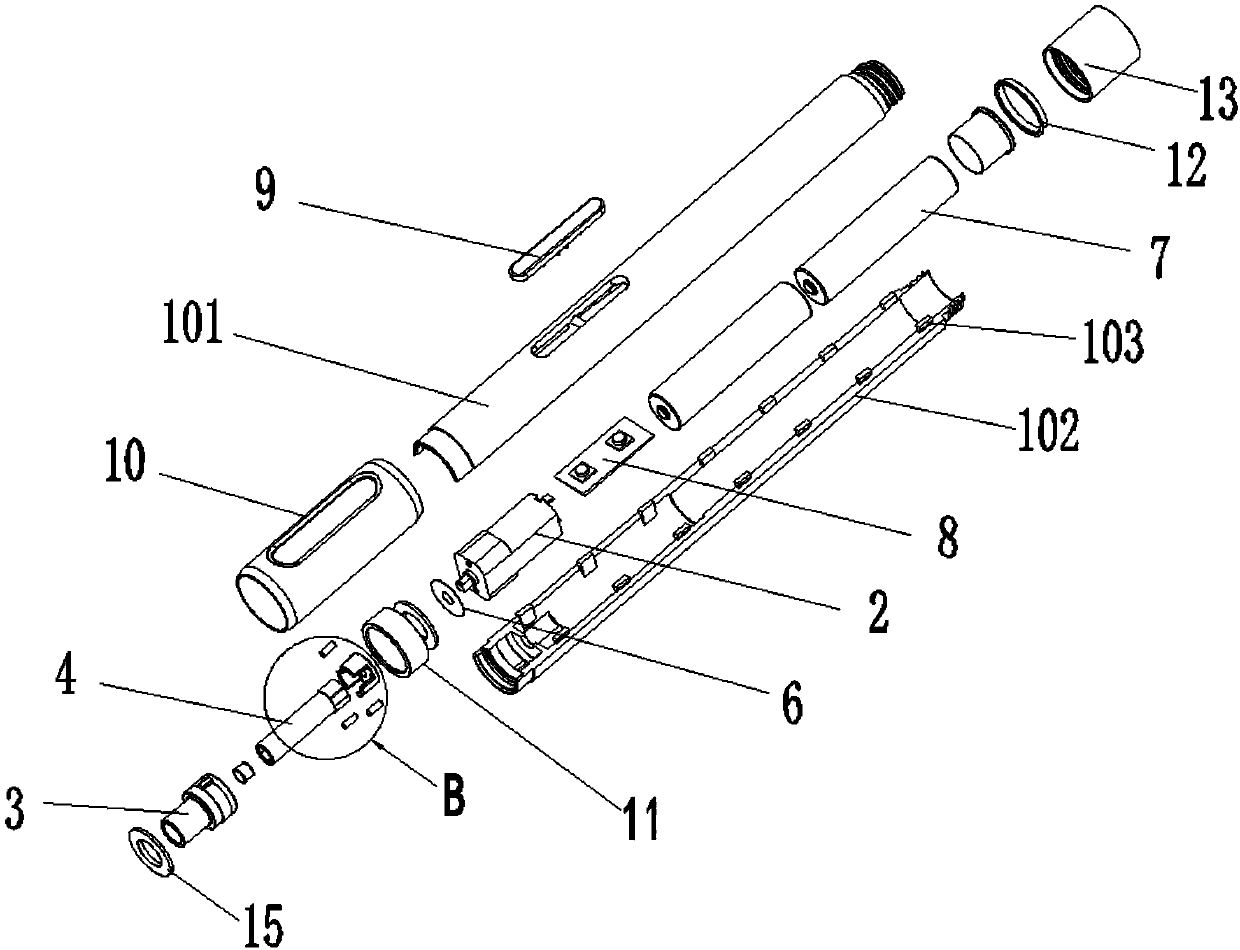

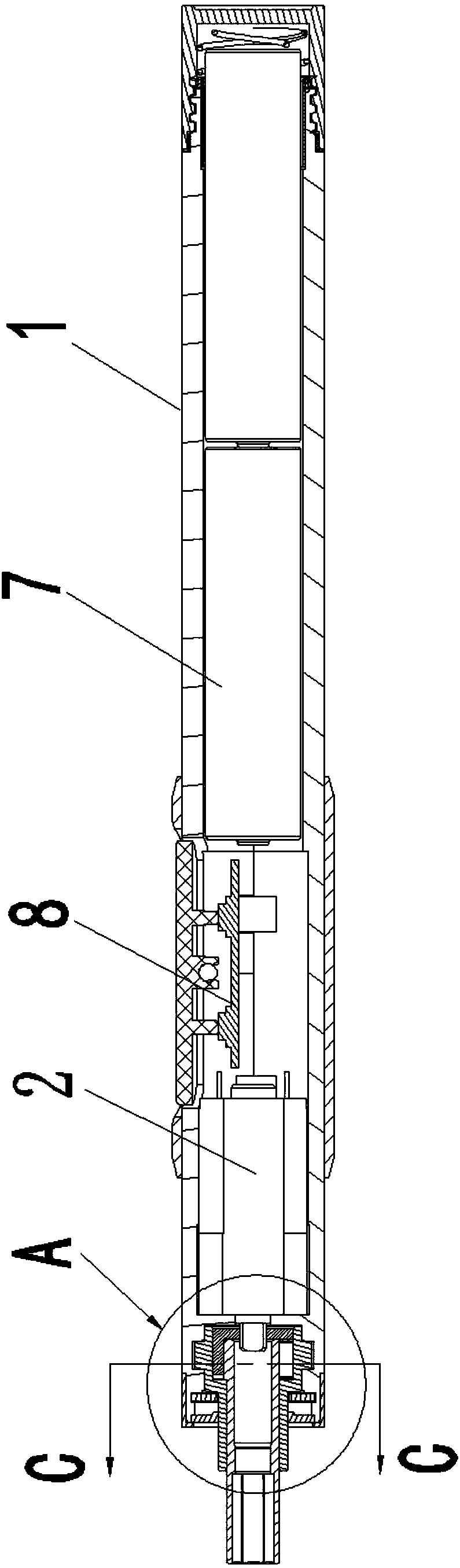

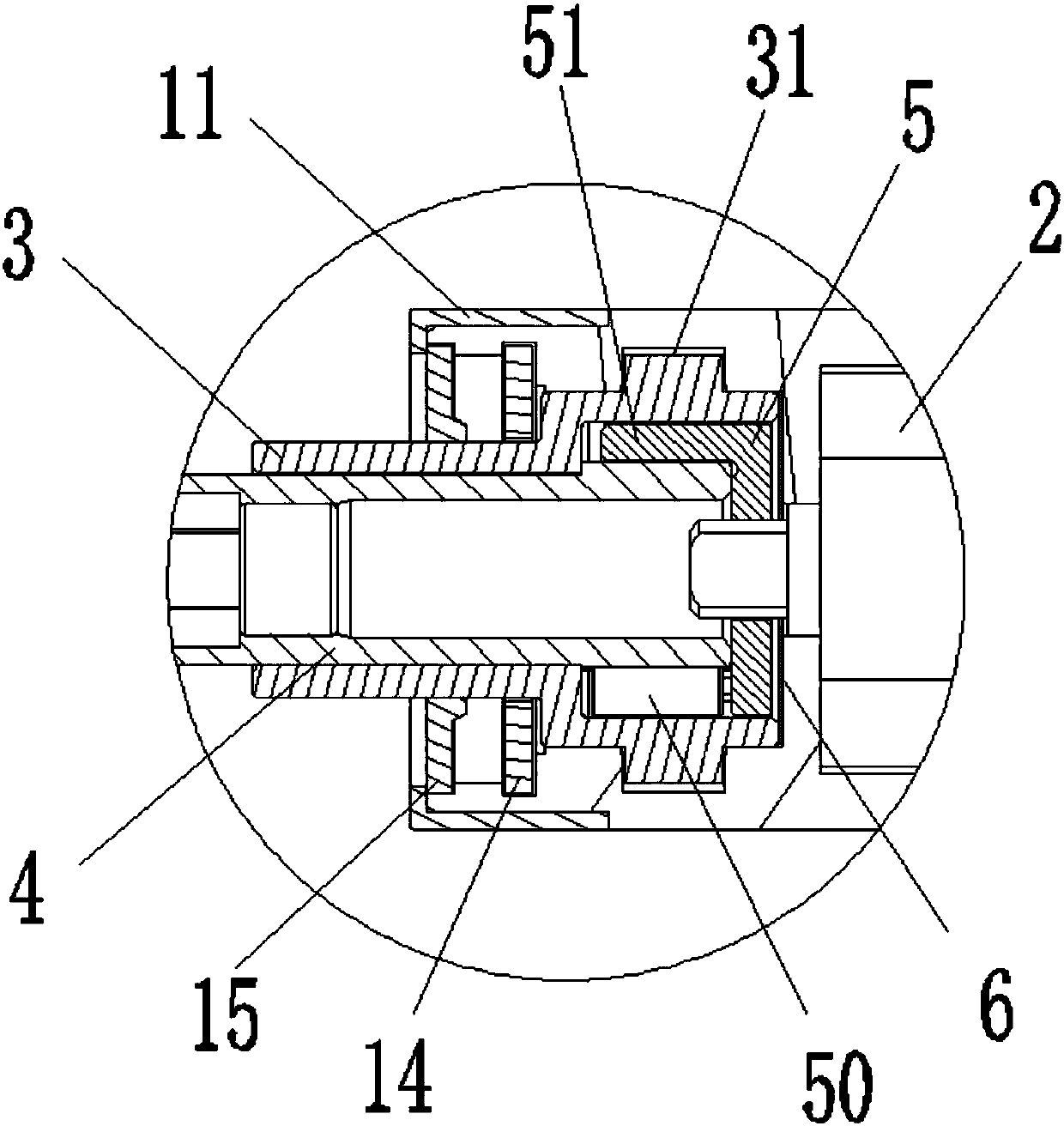

[0032] The invention discloses a precision electric screwdriver, such as Figure 1 to Figure 5 As shown, it includes a screwdriver bit and a housing 1. The housing 1 is a cylindrical structure with a storage space formed by fixing the first housing 101 and the second housing 102 together through a buckle mechanism 103, which is simple Convenient and more reliable. Of course, further ultrasonic welding is also possible.

[0033] The housing space of the housing 1 is provided with a motor 2, a battery 7 and a circuit board 8 with a switch, the housing is provided with a switch button 9 for controlling the switch, and the circuit board 8 is controlled by the switch button. 9. Start and drive the motor 7 to rotate forward or reversel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap