Manual-pneumatic control system for packaging machinery

A technology of pneumatic control system and packaging manipulator, applied in the field of machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

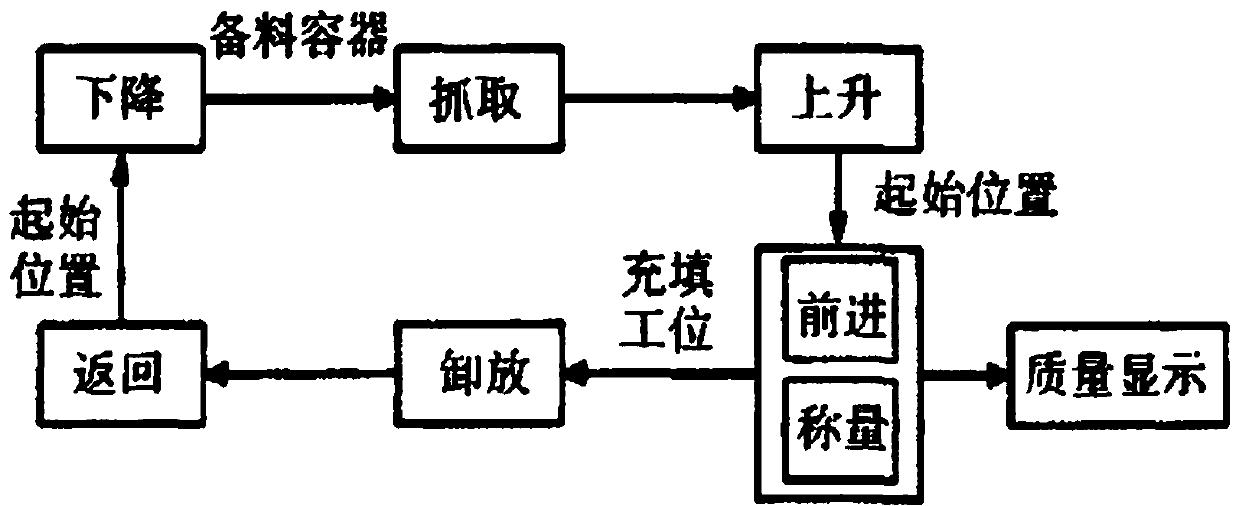

[0015] Such as figure 1 , the design goal is to realize continuous automatic packaging filling and metering of short and small filamentary materials, and the executive parts make cyclical linear horizontal and vertical movements, and the speed must be adjusted during the movement.

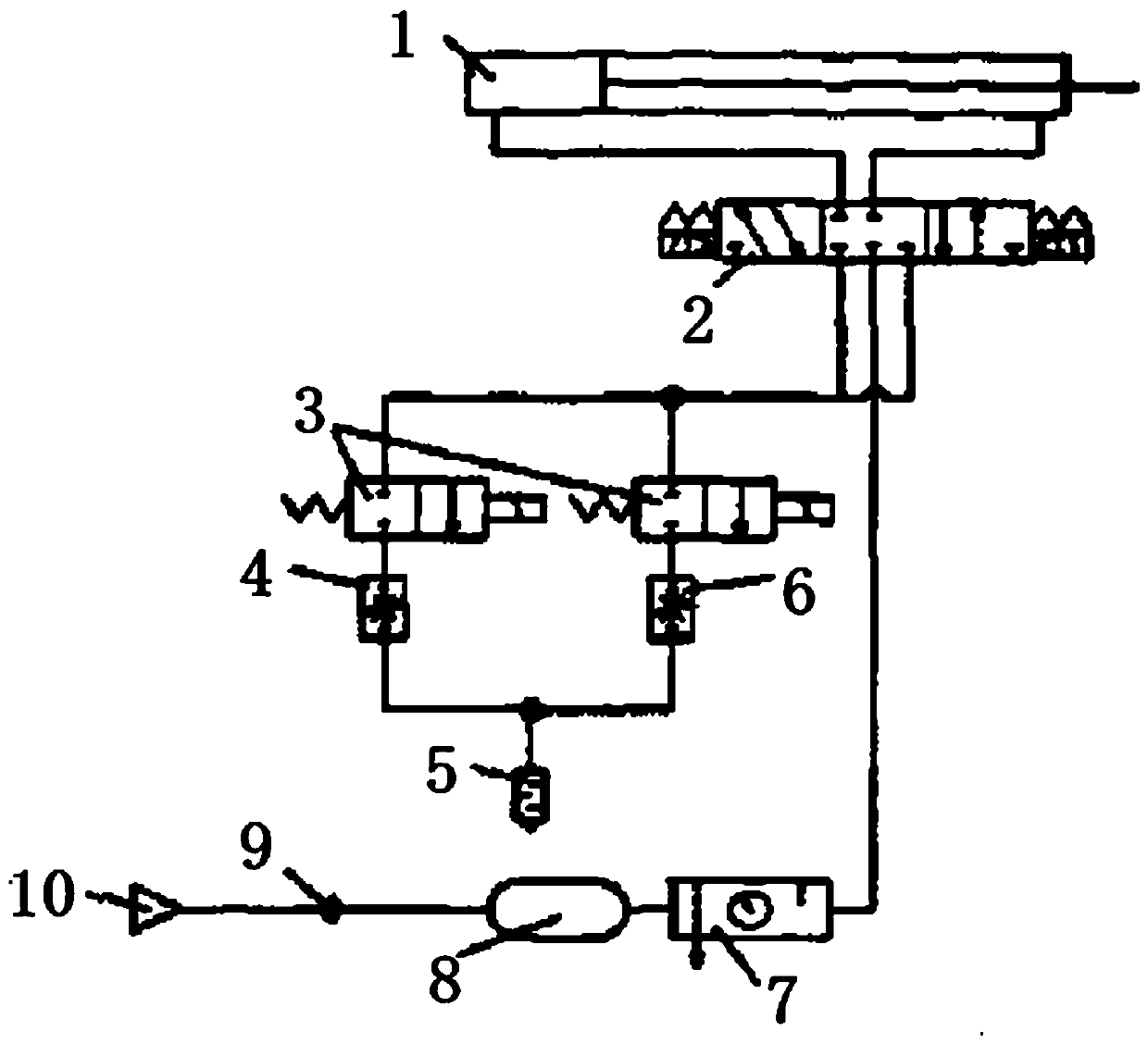

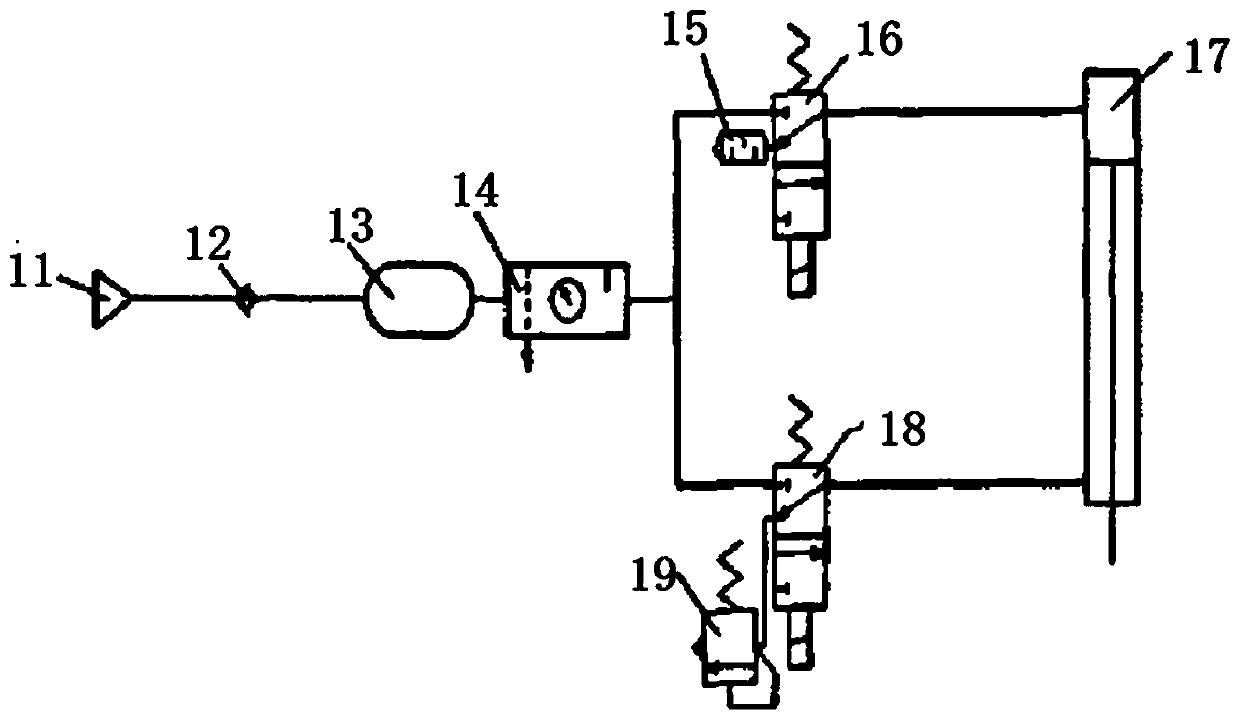

[0016] Such as figure 2 , The pneumatic control system includes the horizontal motion drive system of the packaging filling manipulator, the vertical motion drive system and the extension and contraction drive system of the material hand. The packaging and filling manipulator needs to make fixed-distance circular reciprocating motion between two fixed points in the horizontal direction, and the speed should be fast under the acceptable impact. Therefore, a double-acting cylinder with a buffer and an inductive switch is used as the actuator. The pilot-operated 3-position 5-way double sole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com