Electric pencil sharpener

A pencil sharpener and electric technology, which is applied in the field of stationery, can solve problems such as waste, time and energy consumption of users, and excessive use, so as to avoid excessive planing and achieve effective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

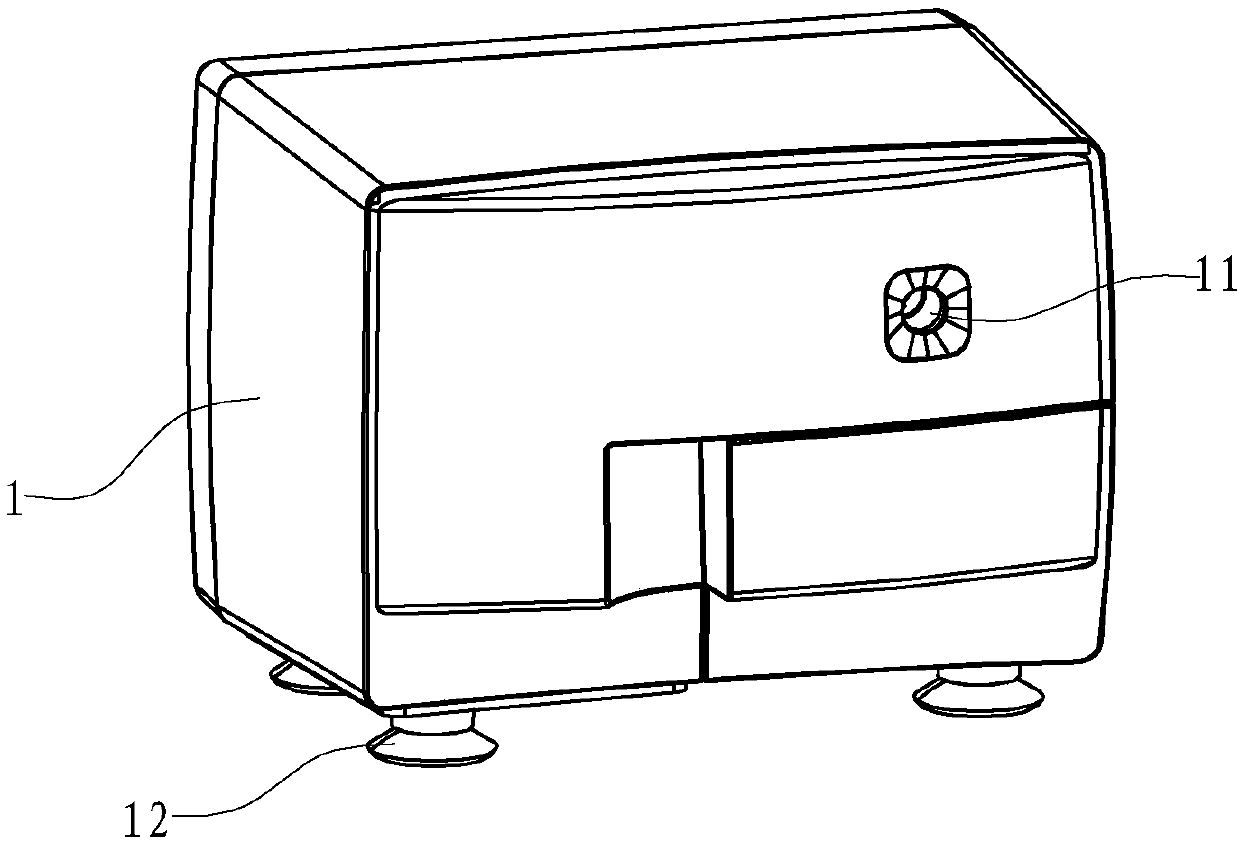

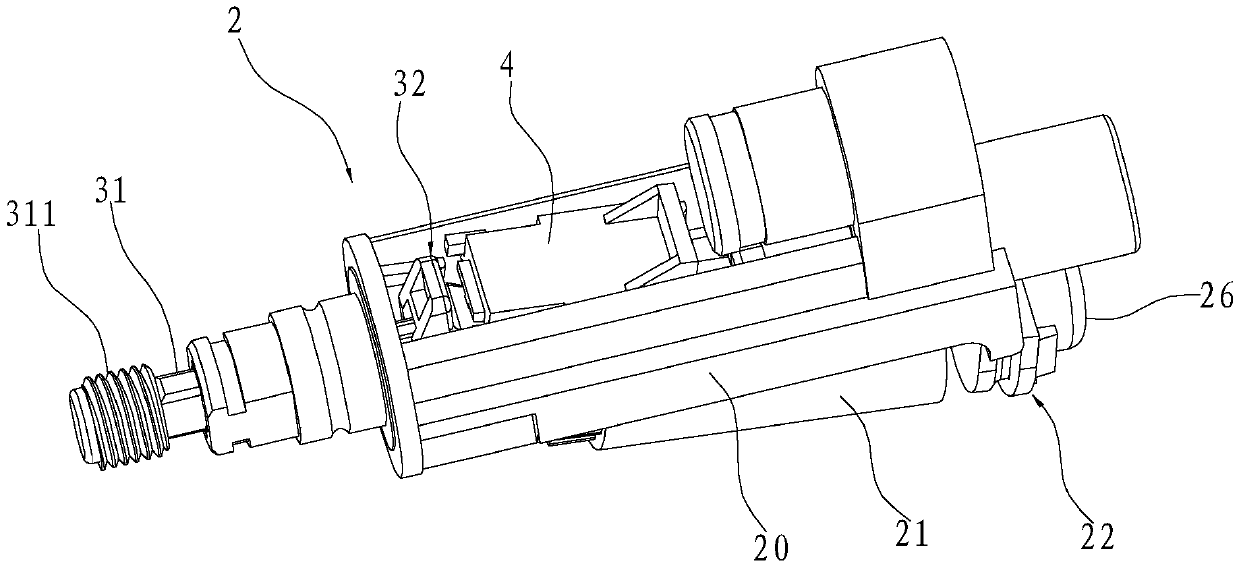

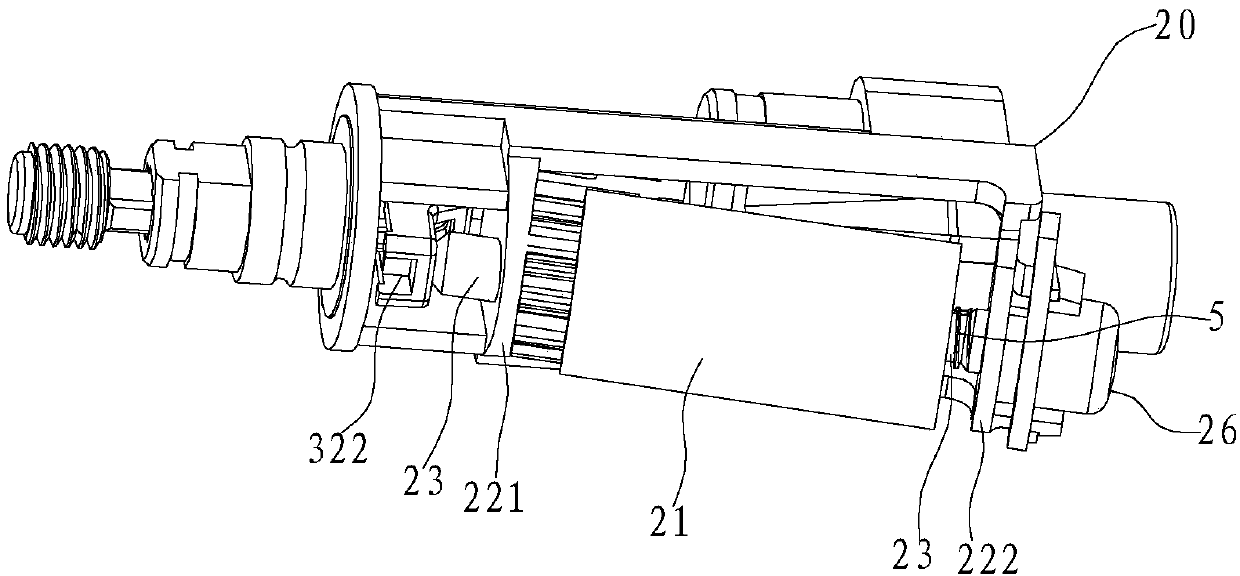

[0021] Such as Figure 1-7 As shown, an electric pencil sharpener includes a casing 1 and a pencil sharpening mechanism 2 arranged in the casing 1, and a suction cup 11 is respectively provided at the four corners of the bottom of the casing 2, so that the sharpening The pen holder is firmly placed on a plane, and the casing 2 is provided with a sharpener hole 11 for inserting a pencil. The pencil sharpening mechanism 2 includes a knife rest 20 and a hob 21. One end of the knife rest 20 is provided with a working hole 25 for inserting a pencil. The working hole 25 communicates with the above-mentioned pencil sharpening hole 11. A knife seat 22 is provided with a knife shaft 23 , the hob 21 is sheathed on the knife shaft 23 , and the hob 21 can rotate around the knife shaft 23 .

[0022] Further, the other end of the tool holder 20 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com