Spinneret measuring pump mounting device

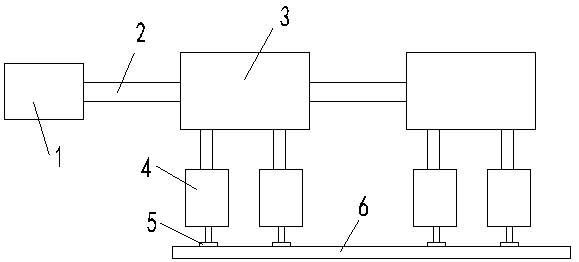

A technology for installing a device and a metering pump, which is applied in the field of metering pump devices, can solve the problems that the operating status of the metering pump cannot be observed in time, is inconvenient to replace, and the transmission box 3 is not easy to find, and achieves high practical value, convenient installation and disassembly, The effect of improving spinning stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

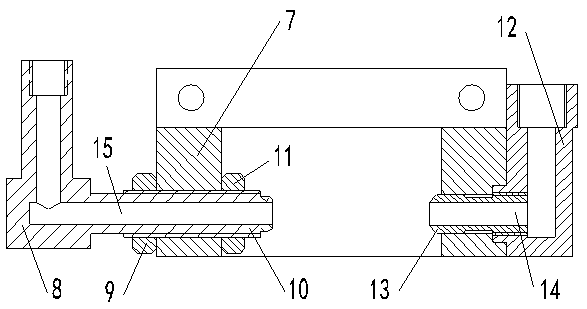

[0015] Such as figure 2 As shown, the installation device of the spinning metering pump of the present invention includes a mounting seat 7, an inlet seat 12 and an outlet seat 8, the mounting seat 7 is C-shaped, one side is open, and the outer side of the opening is respectively provided with an inlet seat 12 and an outlet seat 8 . The inlet seat 12 is provided with an inlet connecting screw 13, through which the entire inlet seat 12 is connected to the mounting seat 7, and the inlet connecting screw 13 extends into the opening of the mounting seat 7, and the inlet seat 12 is processed with a penetrating The feeding hole 14, the feeding hole 14 runs through and also includes the inlet connecting screw 13 (the inlet connecting screw 13 is hollow). The inlet connection screw 13 can be integrated with the inlet seat 12, or it can be as figure 2 As shown, it is processed separately and then assembled together.

[0016] The outlet seat 8 is provided with an outlet connecting ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap