Manufacturing method of sound barrier unit plate through prestressed reactive powder concrete

A technology of active powder and concrete, which is applied in the direction of noise absorption devices and buildings, can solve the problems of unit panel damage, endangering the safety of trains, and insufficient fatigue resistance, and achieves improved crack resistance, increased rigidity, and simple methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below, and the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0018] Example:

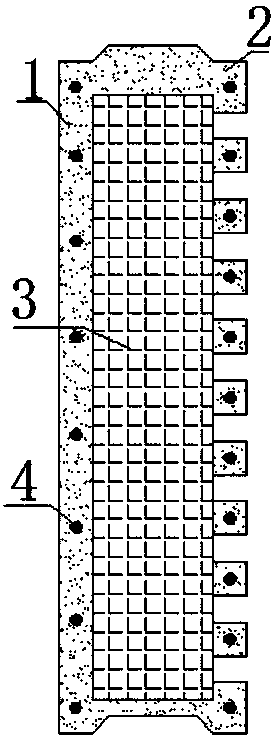

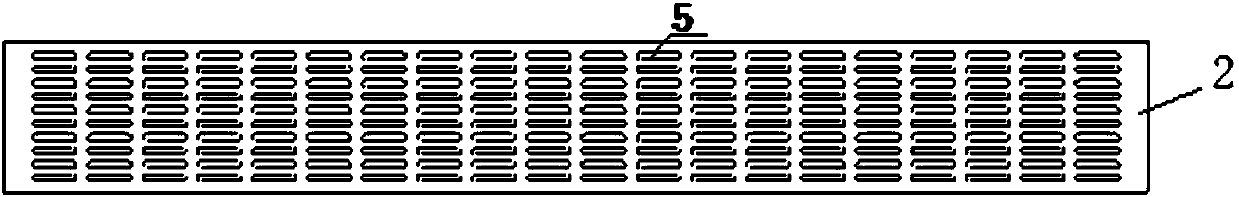

[0019] Such as Figure 1-4 shown.

[0020] 1. Reserve two rows of upper and lower holes on the end plates 7 at both ends of the steel formwork, the hole diameter is 6mm, and the upper and lower holes are arranged at equal intervals. The spacing of the upper row of holes is 65mm, and the spacing of the lower row of holes is 45mm.

[0021] 2. Pass the high-strength steel wire 4 with threads at both ends through the holes on the end plates 7 at both ends of the steel formwork. The diameter of the high-strength steel wire 4 is 4mm, and the high-strength steel wire is stretched by tight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap