Method for shutting off cylinders and reducing torsion of gasoline engines

A gasoline engine and cylinder cut-off technology, which is applied in mechanical equipment, engine control, machine/engine, etc., can solve the high cost of implementation, cannot apply to conventional gasoline engines to reduce torque and cut cylinders, and has no ideal solution to the fast response requirements of torque reduction. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] specific implementation plan

[0048] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

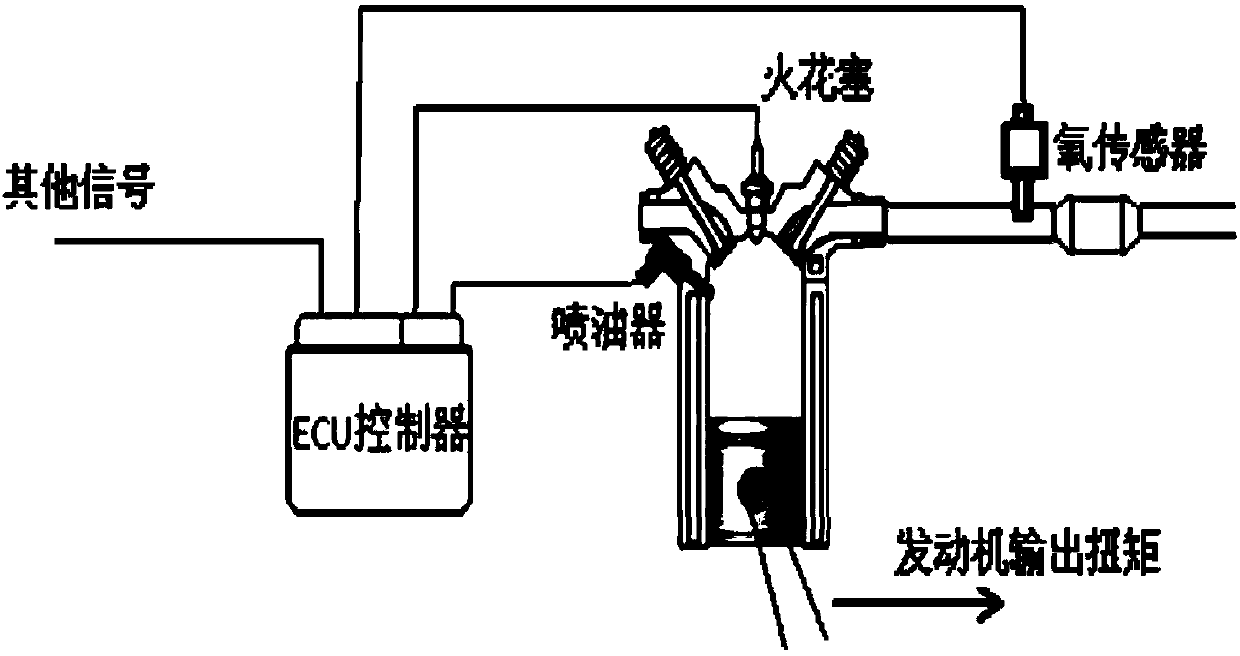

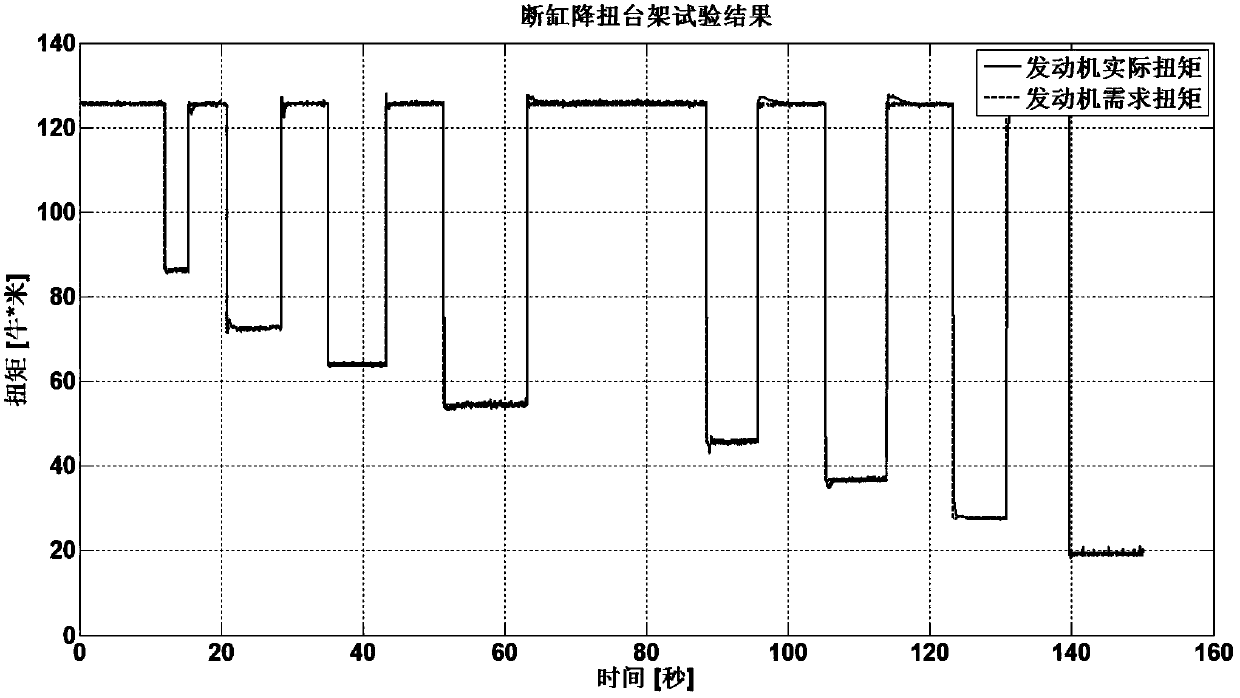

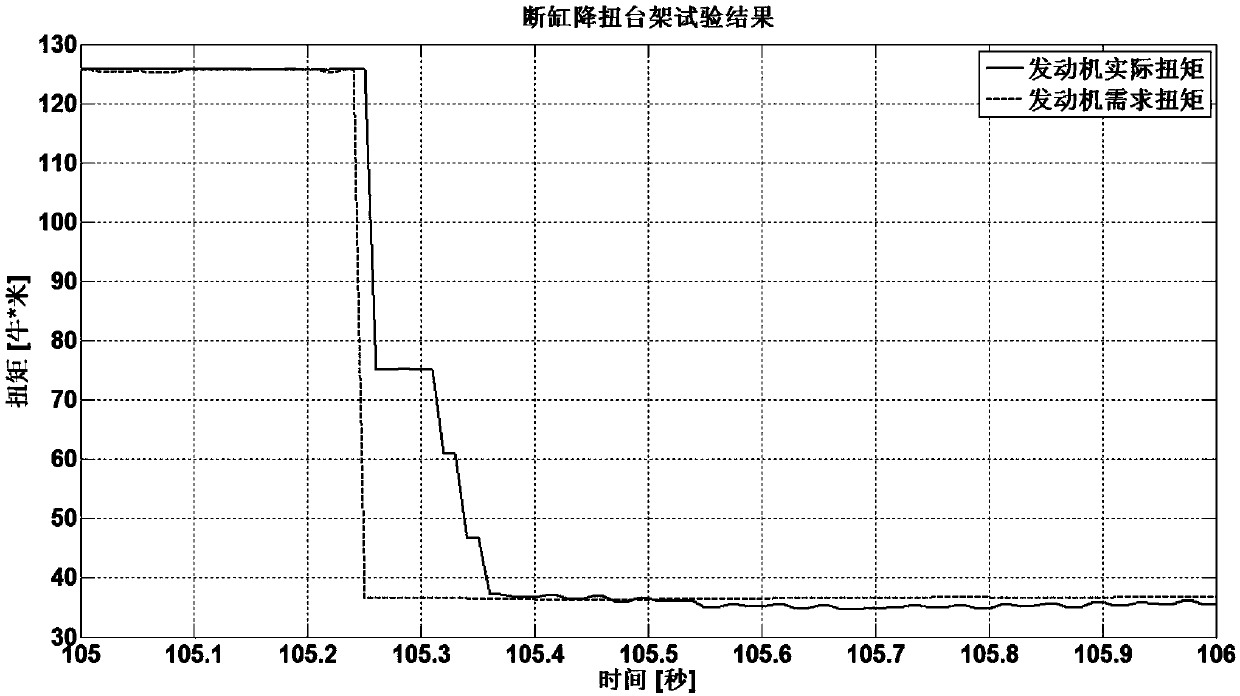

[0049] See attached figure 2 , 7 Summary of the invention: the present invention provides a kind of method for reducing torsion by disconnecting the cylinder of gasoline engine, which can reach better effect of reducing the torsion by cutting off the cylinder. Taking a 1.2L displacement four-cylinder direct injection gasoline engine as an example, the entire strategy implementation process uses the synchronization signal time as the calculation step;

[0050] Step 1. Judgment of the cylinder cut-off condition based on the relationship between the required torque and the minimum ignition angle torque in the ECU. If the output torque is less than the required torque of the engine, then no cylinder disconnection and torque reduction will be performed at this time; if the minimum engine output torque is grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com