motor control unit

A motor control and motor speed technology, applied in motor control, motor generator control, AC motor control, etc., can solve the problems of mechanical system impact, torque constant change, output torque sudden change, etc., and achieve safe deceleration characteristics, Improved torque reduction and overcurrent prevention effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

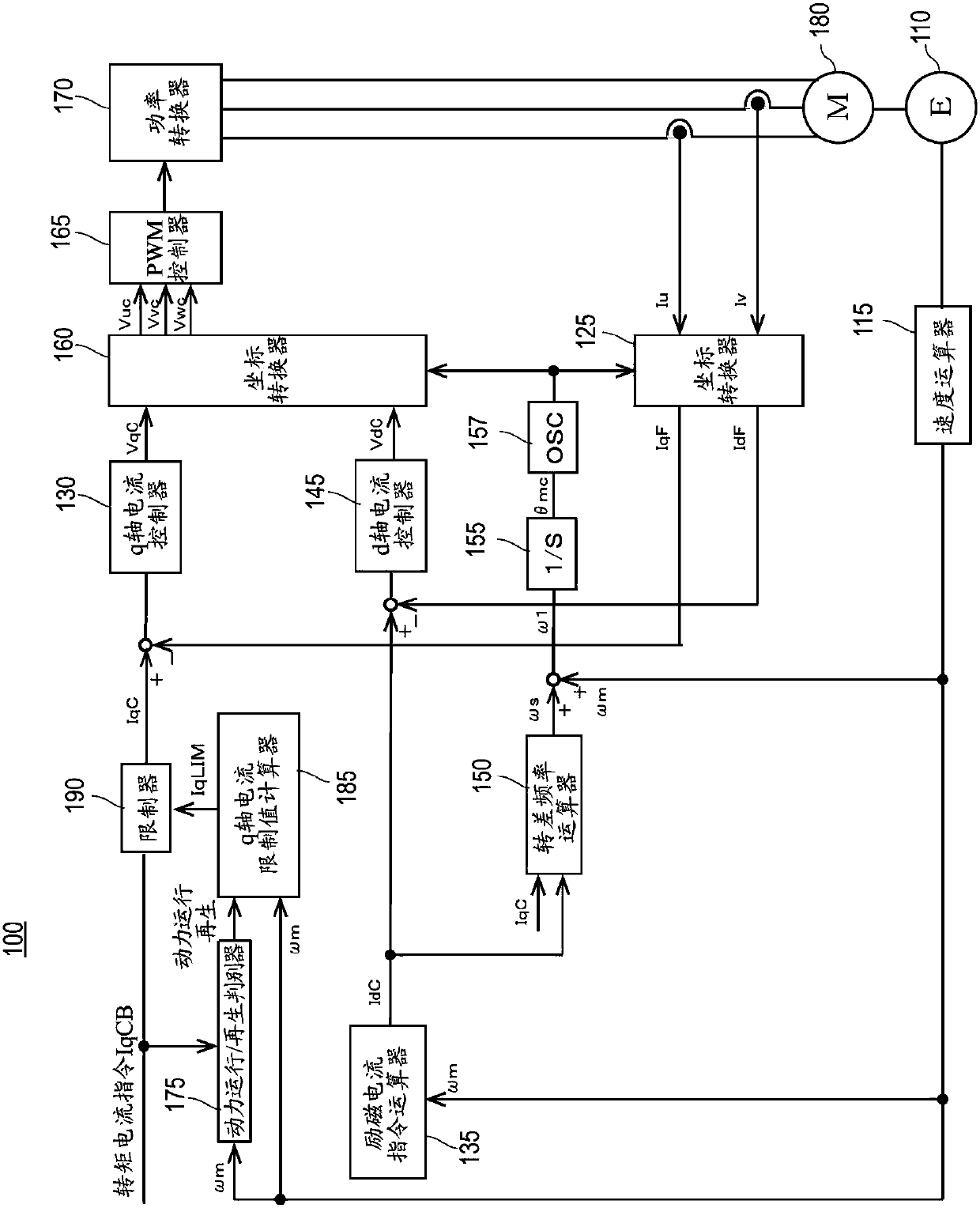

[0062] [Overall Structure of Motor Control Device 100]

[0063] figure 1 It is a block diagram of the motor control device 100 of Embodiment 1.

[0064] The motor control device 100 includes a q-axis current controller 130 , a power running / regeneration discriminator 175 , a q-axis current limit value calculator 185 , and a limiter 190 as a system for giving a q-axis voltage command VqC.

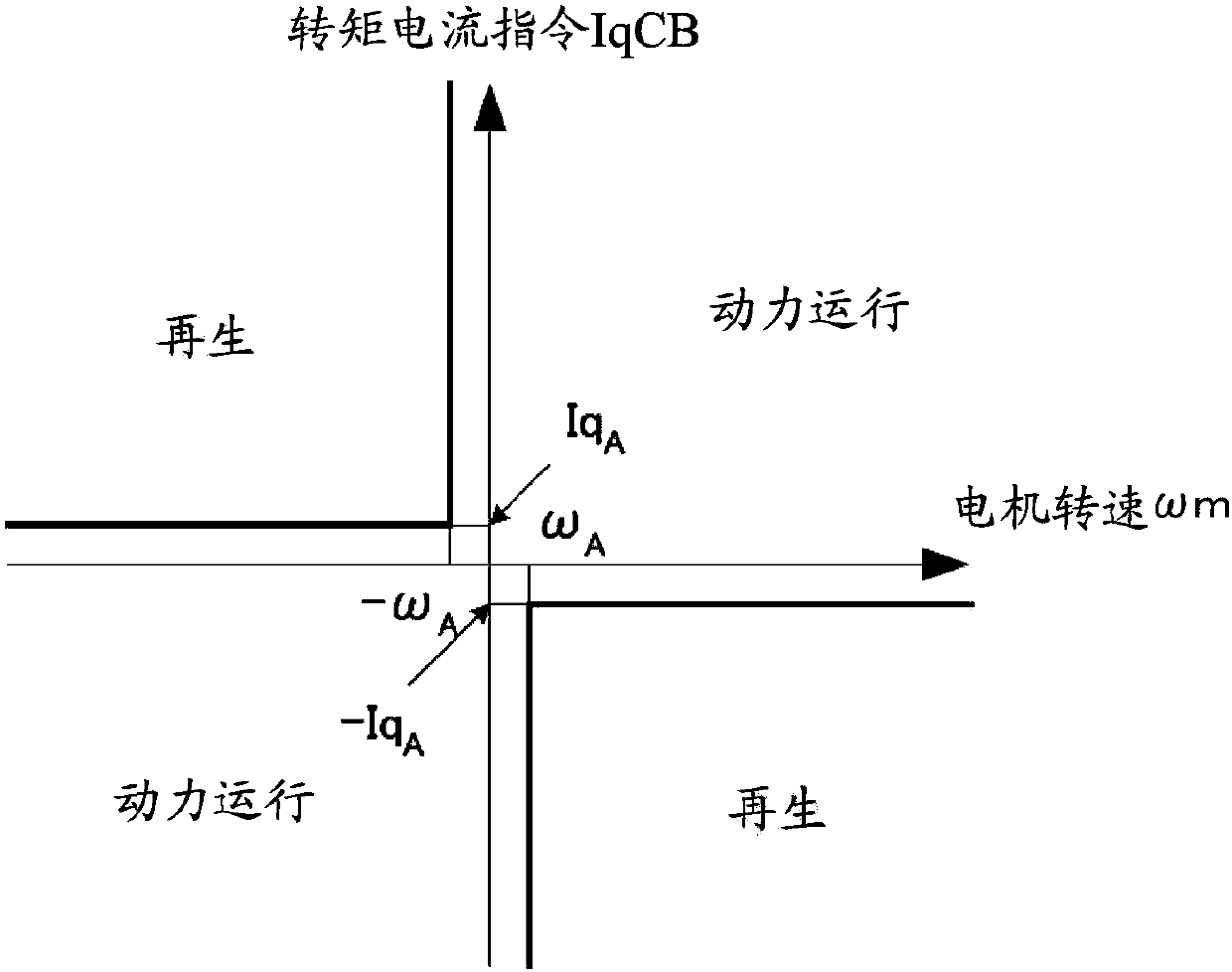

[0065] The power running / regeneration determiner 175 determines whether the motor 180 is in the power running state or in the regenerative state based on the torque current command IqCB and the motor rotation speed ωm. The motor rotation speed ωm is output by the speed calculator 115 . The speed calculator 115 calculates the motor rotational speed ωm using the position feedback detected by the encoder 110 . Note that the detailed operation of power running / regenerating determiner 175 will be described later.

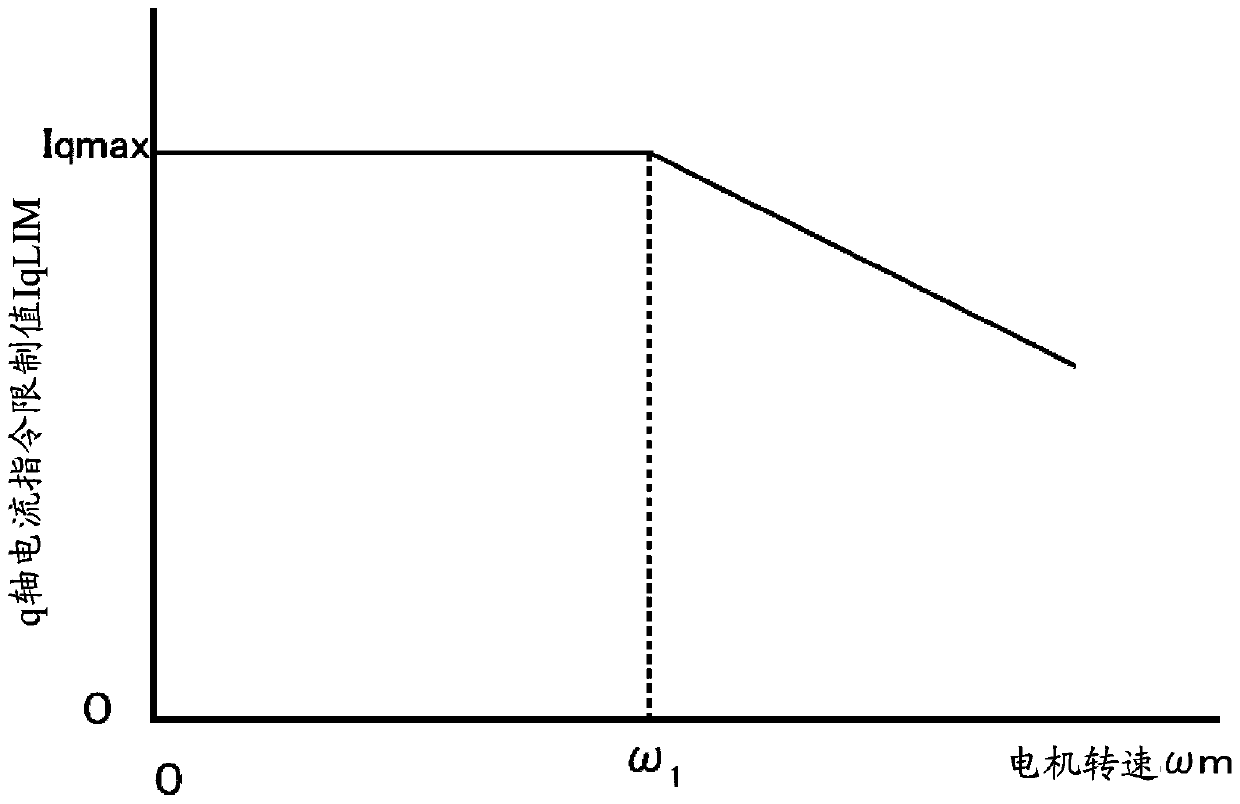

[0066] The q-axis current limit value calculator 185 calculates the q-axis cu...

Embodiment approach 2

[0126] [Overall Structure of Motor Control Device 200]

[0127] Image 6 It is a block diagram of the motor control device 200 of Embodiment 2. The motor control device 200 of Embodiment 2 adds a magnetic flux controller and a magnetic flux calculator to the configuration of the motor control device 100 of Embodiment 1, and includes a magnetic flux command calculator instead of the field current command calculator 135 .

[0128] The motor control device 200 includes a q-axis current controller 230 , a power running / regeneration discriminator 275 , a q-axis current limit value calculator 285 , and a limiter 290 as a system for giving a q-axis voltage command VqC. The q-axis current controller 230, the power running / regeneration discriminator 275, the q-axis current limit value calculator 285, and the limiter 290 are the same as the q-axis current controller 130, the power running / regeneration discriminator 175, and the q-axis current The limit value calculator 185 and the lim...

Embodiment approach 3

[0177] [Overall Structure of Motor Control Device 300]

[0178] Figure 9 It is a block diagram of the motor control device 300 of Embodiment 3. The motor control device 300 of the third embodiment adds a maximum primary current command calculator, a torque limit value calculator, and a q-axis current calculator to the configuration of the motor control device 200 of the second embodiment.

[0179] The motor control device 300 is a system that provides a q-axis voltage command VqC, and includes a q-axis current controller 330 , a power running / regeneration discriminator 375 , a maximum primary current command calculator 383 , a torque limit calculator 385 , and a limiter 390 and a q-axis current calculator 395 . The q-axis current controller 330 and the power running / regeneration discriminator 375 are the same as the q-axis current controller 230 and the power running / regeneration discriminator 275 of the second embodiment.

[0180] The maximum primary current command calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com