Upstream propellant temperature control device used after stopping of attitude and orbit control engine

A temperature control device and engine technology, applied in rocket engine devices, jet propulsion devices, machines/engines, etc., can solve problems such as the inability of traditional methods to be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

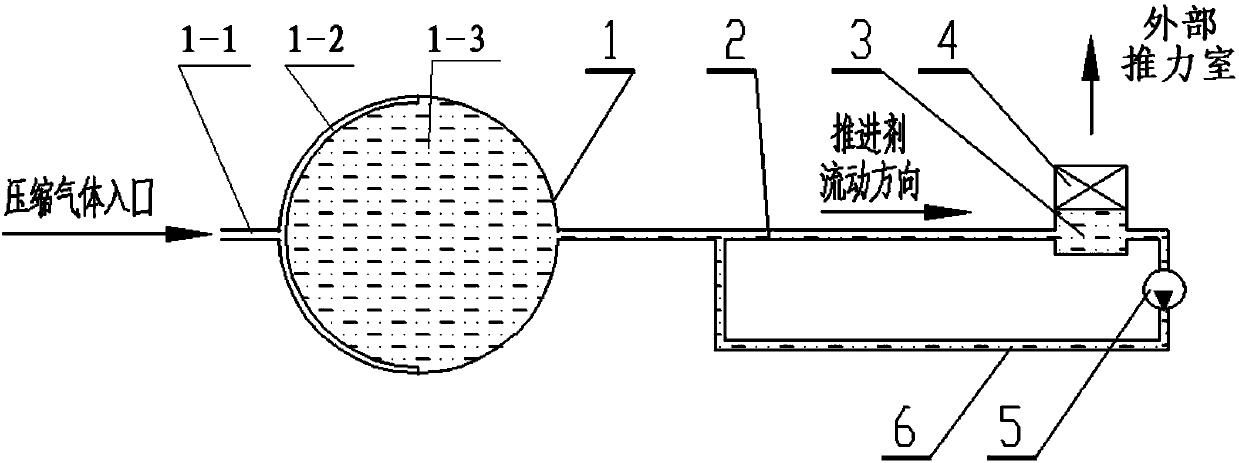

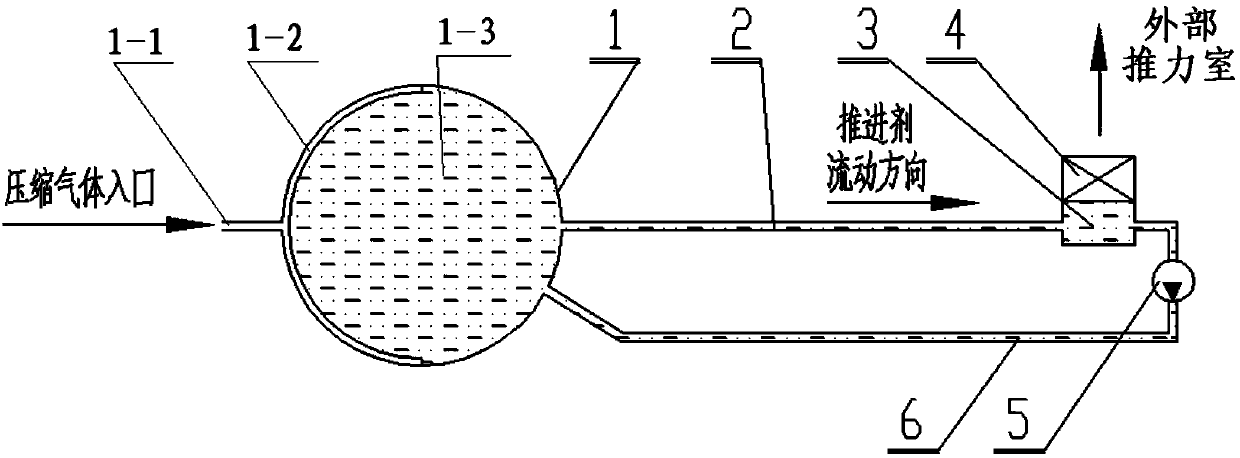

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0024] The purpose of the present invention is to control the temperature of the pre-valve propellant (including the propellant in the cooling channel of the regenerative cooling engine) after the orbit attitude control engine is stopped within a safe range in as many applications as possible.

[0025] The present invention proposes a new device for controlling the temperature of the pre-valve propellant (including the propellant in the cooling channel of the regenerative cooling engine) after the rail attitude control engine stops, which can replace the above-mentioned traditional propellant temperature control device in function, and can adapt to More applications. The method is characterized in that by setting the circulation pump 5, when the engine electromagnetic valve 4 is closed, the circulation pump 5 is started to circulate the propella...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com