Novel high-speed switch valve

A high-speed on-off valve, a new type of technology, used in fluid pressure actuation devices, servo motor components, mechanical equipment, etc., can solve the problem of not being able to handle large flow and high response at the same time, and achieve good high-speed response performance, stable operation, Good high flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

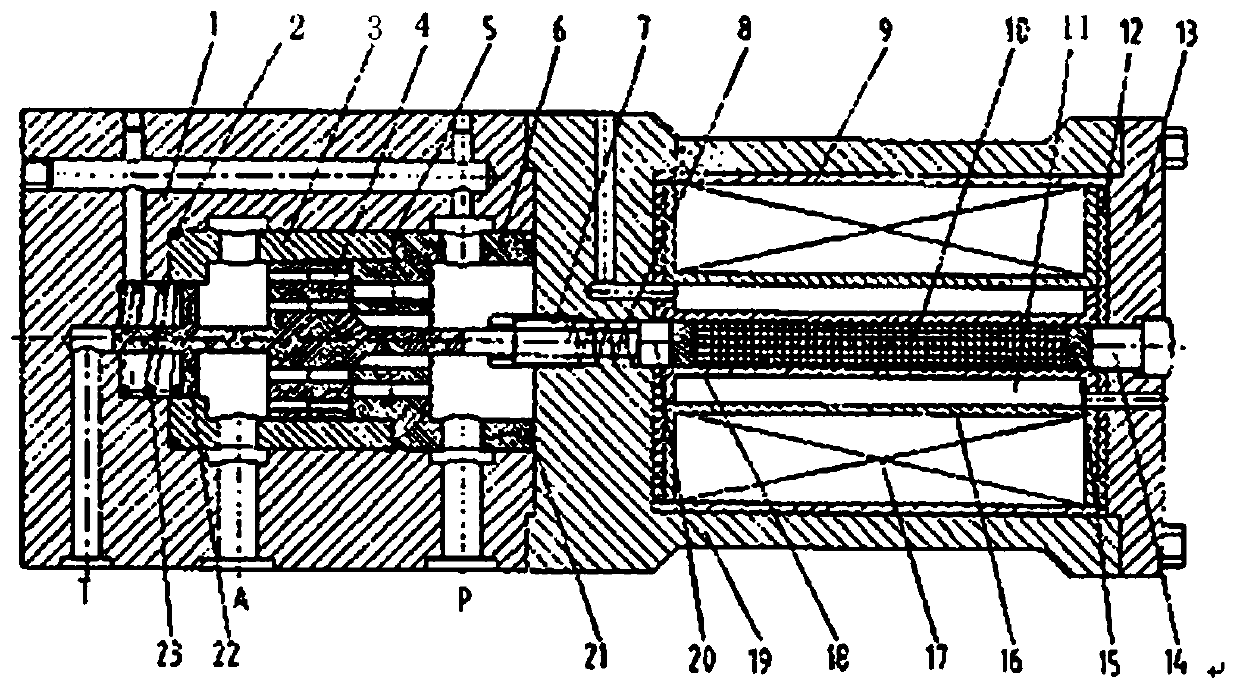

[0011] Preferably, when the valve port is closed, the imported hydraulic oil acts on the matching taper surface of the valve core and the valve seat, and at the same time, the imported pressure oil is guided to the force balance plate on the left side of the valve core through the oil passage on the valve body, and the force balance plate The area on the left is equal to the sum of the areas of the taper surfaces where the spool and seat fit. At this time, the hydraulic pressure at both ends of the spool is balanced and is only affected by the force of the return spring.

[0012] Preferably, when the coil 17 is energized, a magnetic field is generated in the GMM rod 10, and the GMM rod is axially elongated, and the output force overcomes the pre-compressed spring force, the hydraulic power of the valve port, the return spring force and the frictional force, and the valve port is opened instantly, P Port and A port are connected.

[0013] Preferably, when the valve port is open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com