Intramode injection molding thin film switch

A technology of membrane switch and in-mold injection molding, which is applied in the field of electronics, can solve problems such as inability to fit complex structural products, high glue requirements, and low product durability, and achieve excellent high temperature and high pressure resistance, simplified production processes, and long service life. prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

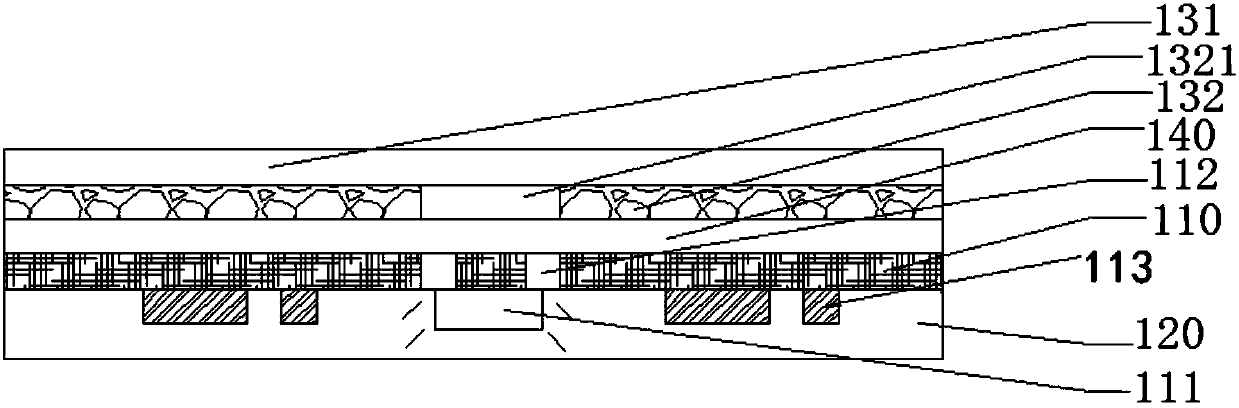

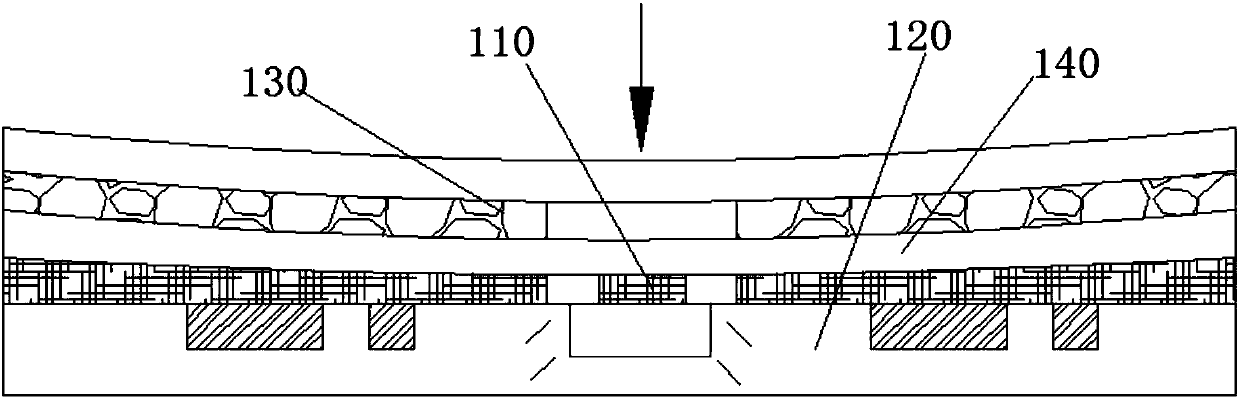

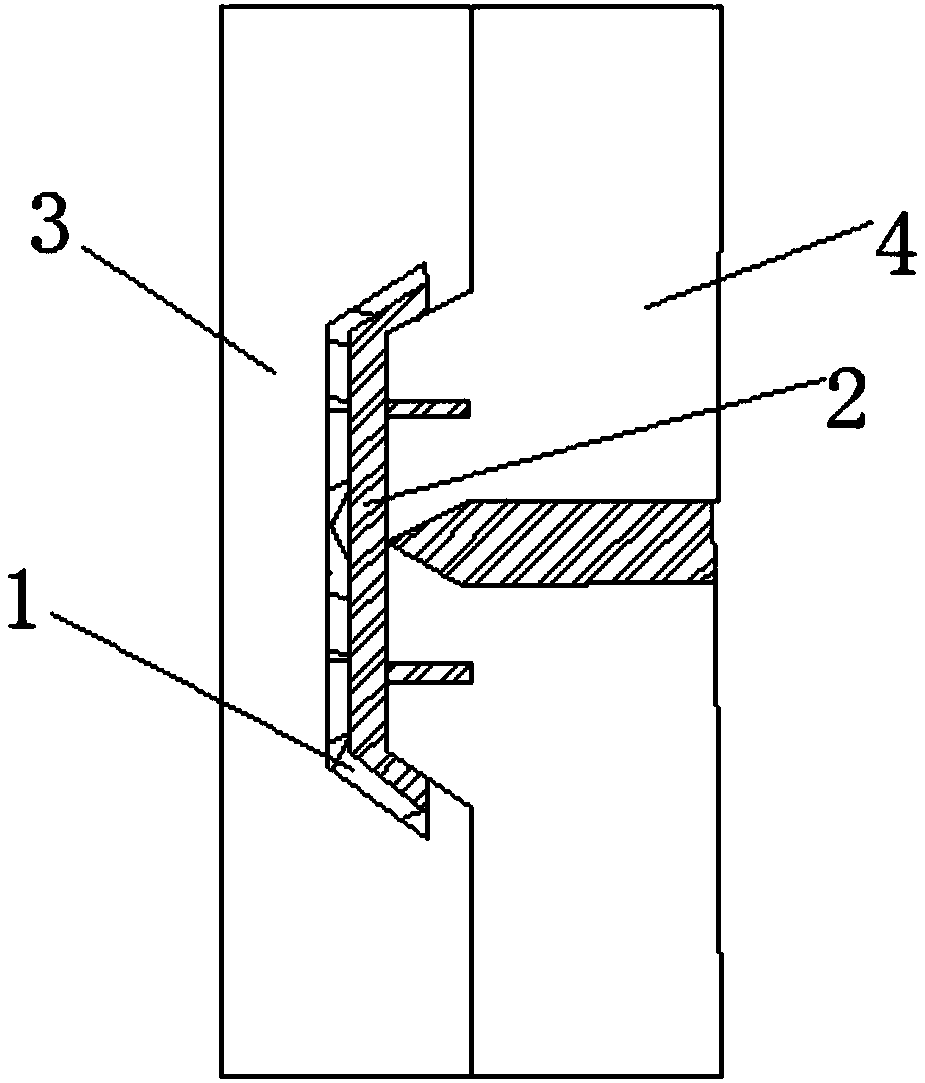

[0030] Such as figure 1 As shown, an in-mold injection molded membrane switch, the membrane switch 1 includes a conductive circuit layer 110, wherein the conductive circuit layer 110 is located at the bottom of the plastic membrane switch 1, the conductive circuit layer 110 is a flexible circuit board (FPC), and the flexible circuit board Injection molding compound layer 120 is provided on the lower surface of the body, the thickness of injection molding compound layer 120 is 0.2mm, the thickness of flexible circuit board is 0.6mm-0.8mm, and the base material of flexible circuit board is polyimide or polyester film.

[0031] The components on the flexible circuit board are arranged on the lower surface of the flexib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com