Assembled constant pressure cabin

A prefabricated and ballasted technology, applied in medical science, hospital equipment, treatment rooms, etc., to reduce manufacturing and transportation costs and facilitate transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

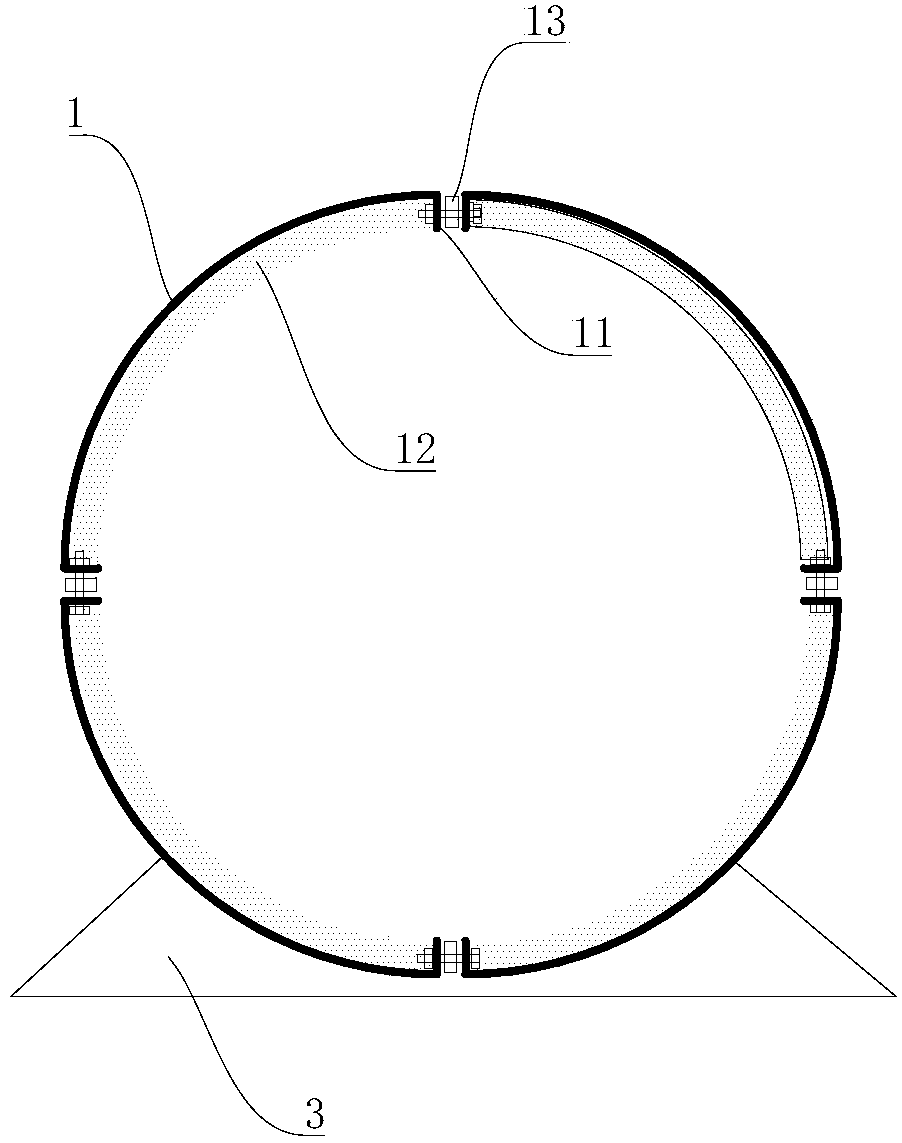

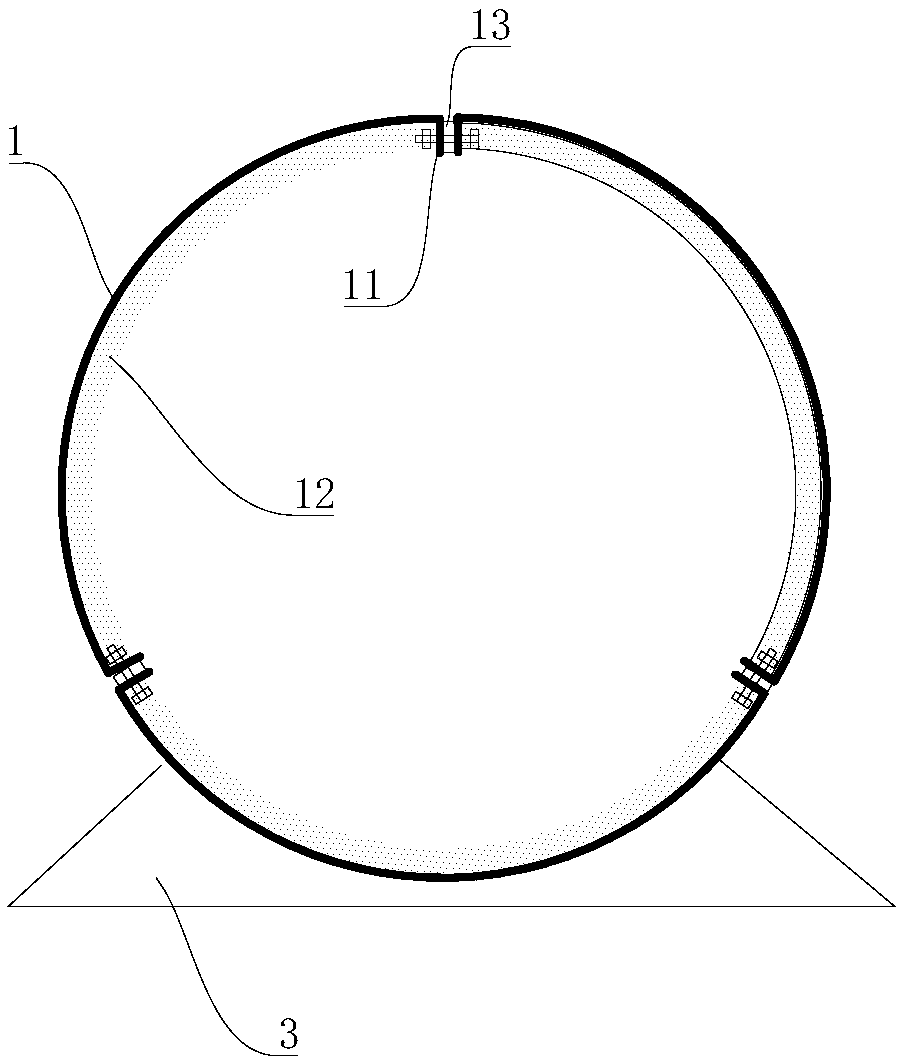

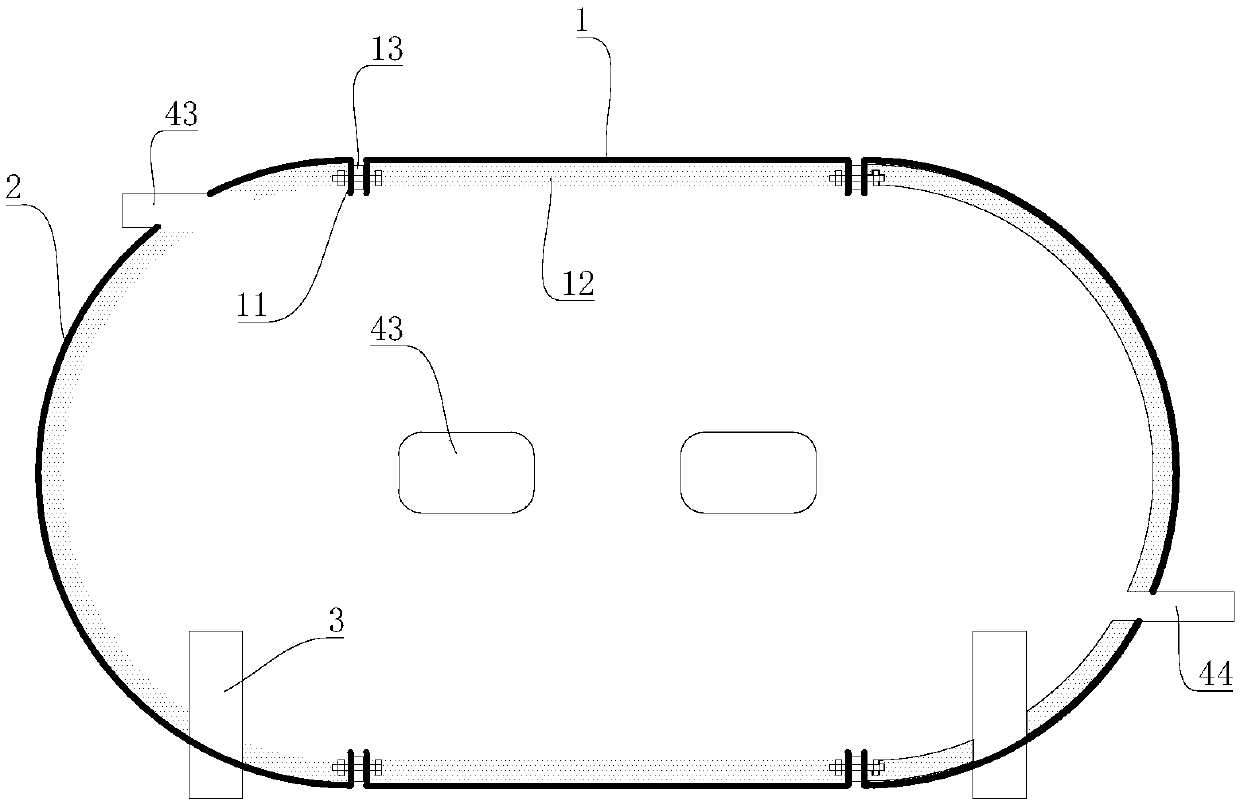

[0021] The prefabricated constant pressure cabin includes at least two independent tank panels. The edge of the tank panels has a connecting surface 11, and the adjacent connecting surfaces 11 of adjacent tank panels are pressed by locking parts, so that all the cabin panels Assembled to form a closed cabin body, a seal 13 is also provided between adjacent connecting surfaces 11; the cabin body is provided with a door 41, a seal is provided at the gap on the edge of the door 41, and the cabin body is also provided with an air intake port 43 and air outlet 44.

[0022] The constant-pressure cabin of the present invention is suitable for providing a normal air pressure environment for patients with altitude sickness, which is beneficial to the treatment and recovery of the patients.

[0023] The constant pressure chamber is formed by assembling the tank shell plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com