Adjustable type concrete beam pouring mold for experiment

A technology for concrete beams and pouring molds, which is applied to molds, mold auxiliary parts, manufacturing tools, etc., and can solve problems such as a large amount of manpower, time-consuming and labor-intensive work, and large volume and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

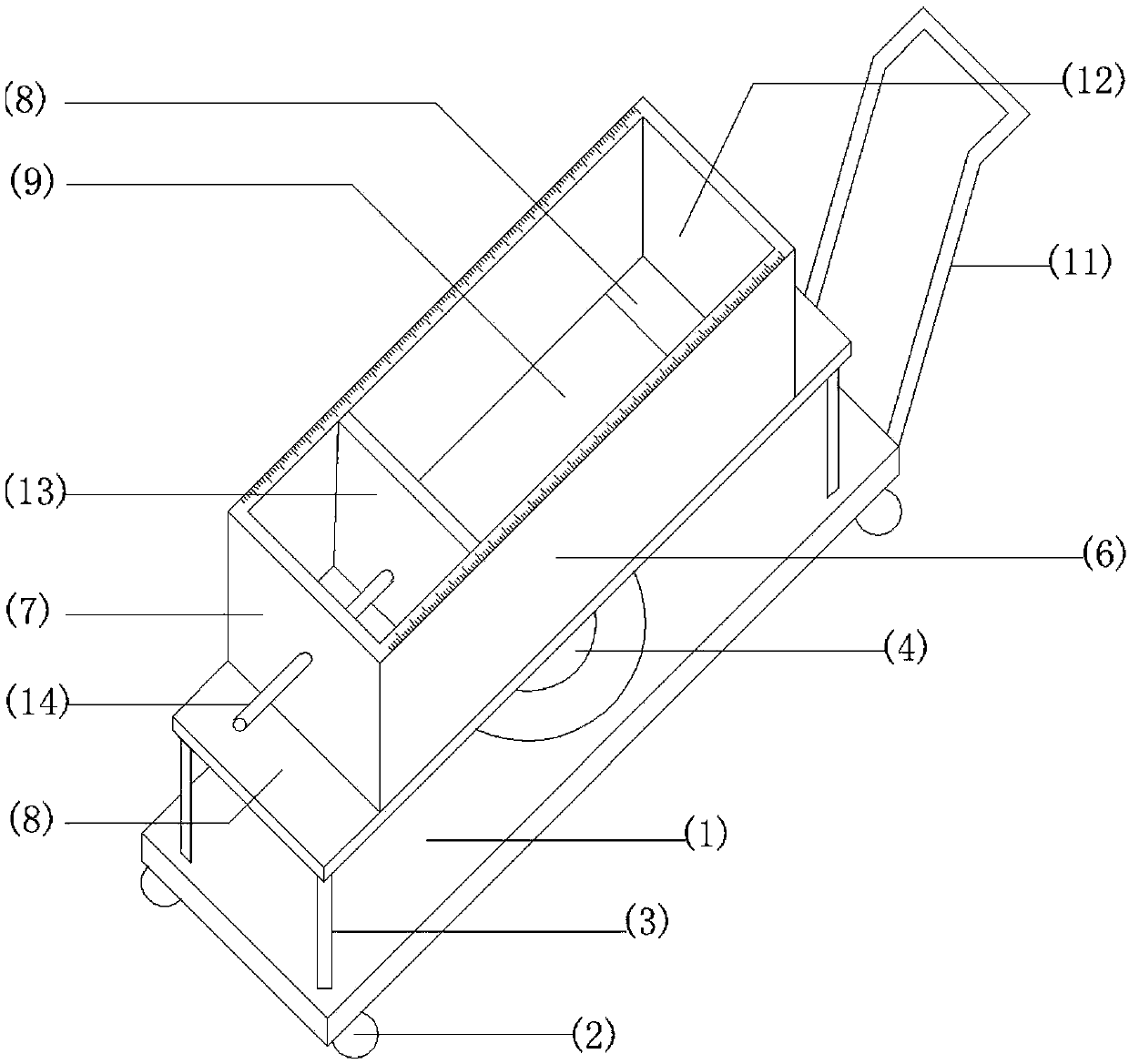

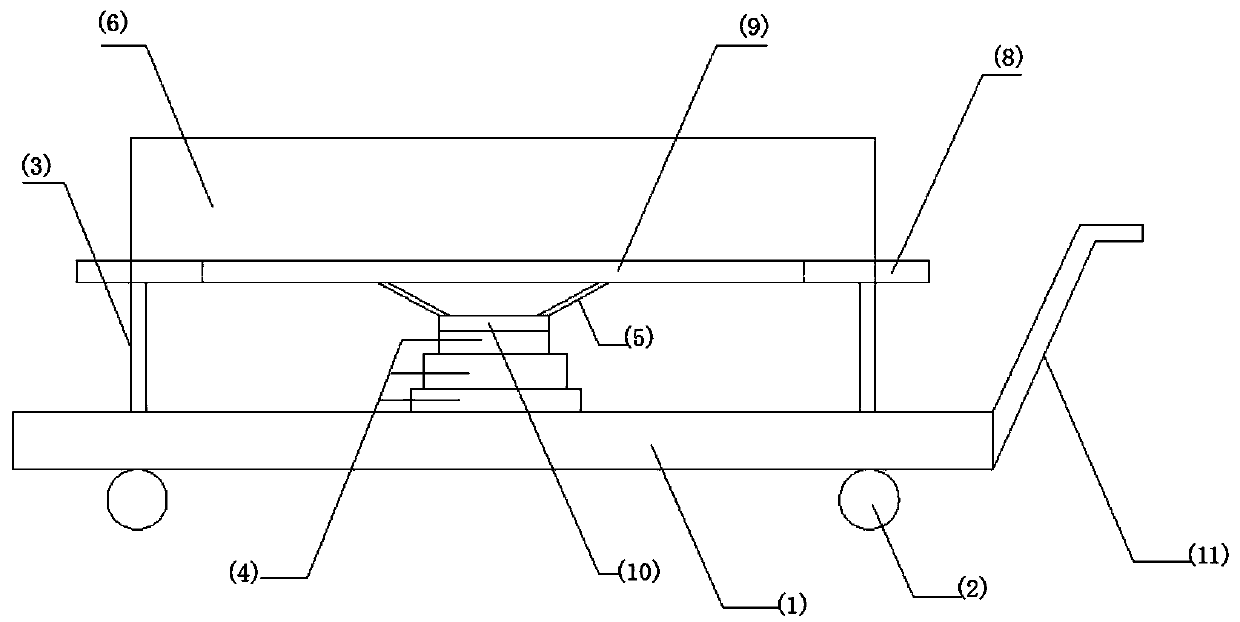

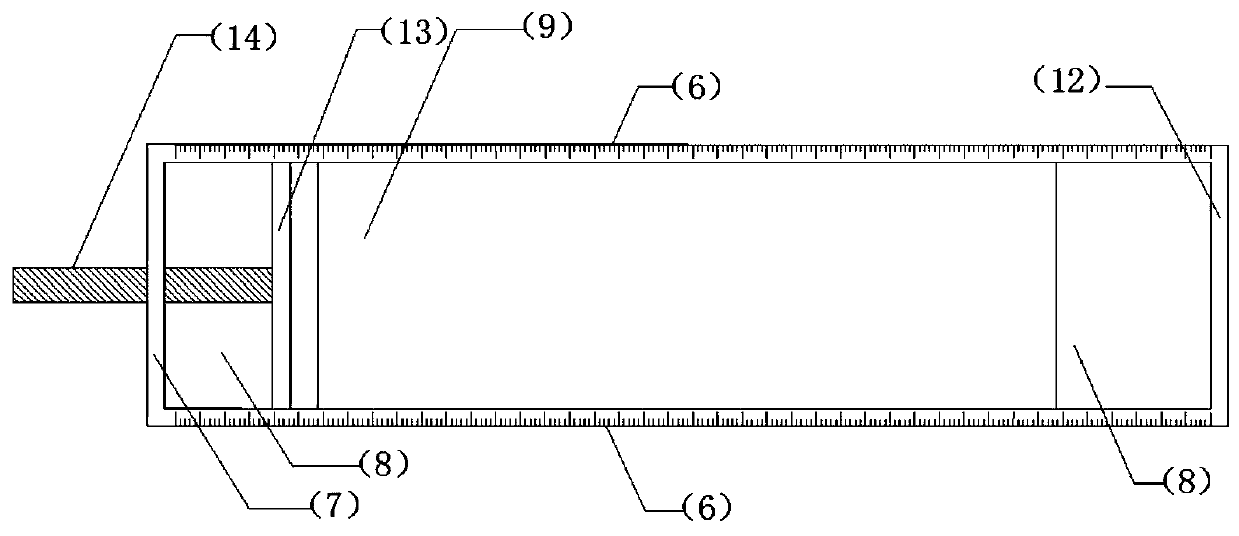

[0018] The base (1) is welded with a handle at one end, and 4 universal wheels are installed below it to facilitate the movement of the components; the lower ends of the four load-bearing rods (3) are welded with the base (1), and the upper ends are welded with the bottom plate (8) to form an integral frame; The load-bearing rod (3) is used to support the upper structure and transfer the load to the base (1). The jack (4) is fixed on the middle of the base (1) by bolts. The upper end of the jack (4) is connected with a rotating ring (10), which is convenient for adjusting the direction when the component is placed on the experimental equipment; the lower ends of the four support rods are welded on the rotating ring, The upper end is connected with the bottom plate (9) and forms a lifting system with the jacks (4). The lifting system receives force when lifting the components, and transmits the load of the components and the template to the base to the ground. The lifting system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com