Basement-roof-post-pouring-belt pre-closing structure and construction method

A technology for basement roof and post-casting belt, which is applied to underwater structures, infrastructure projects, artificial islands, etc., can solve problems such as affecting project development, structural quality, and inability to seal, so as to solve the problem of poor waterproof effect and reduce construction costs. cost, the effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the examples. The following examples are provided only to aid the understanding of the present invention. Those skilled in the art can make improvements to the present invention without departing from the principles of the present invention, and these improvements also fall within the protection scope of the claims of the present invention.

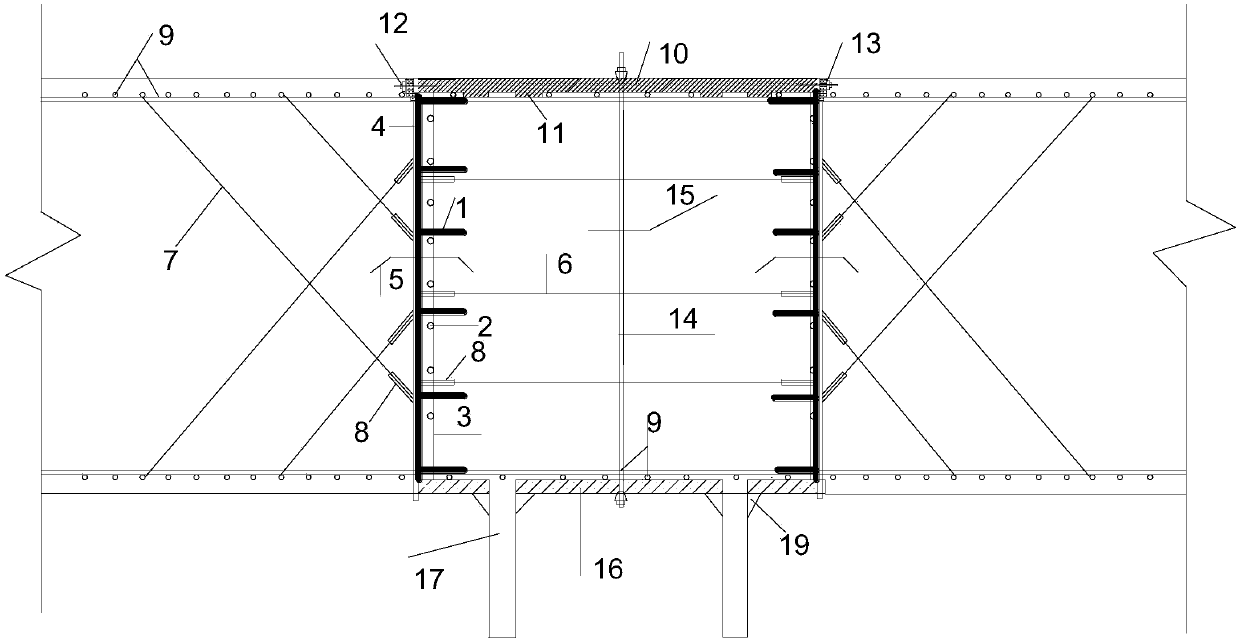

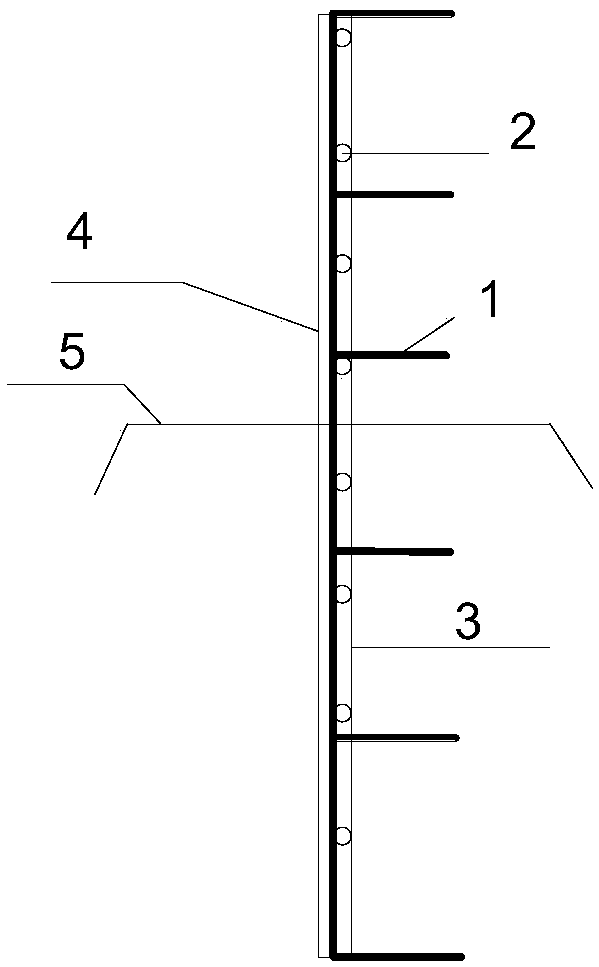

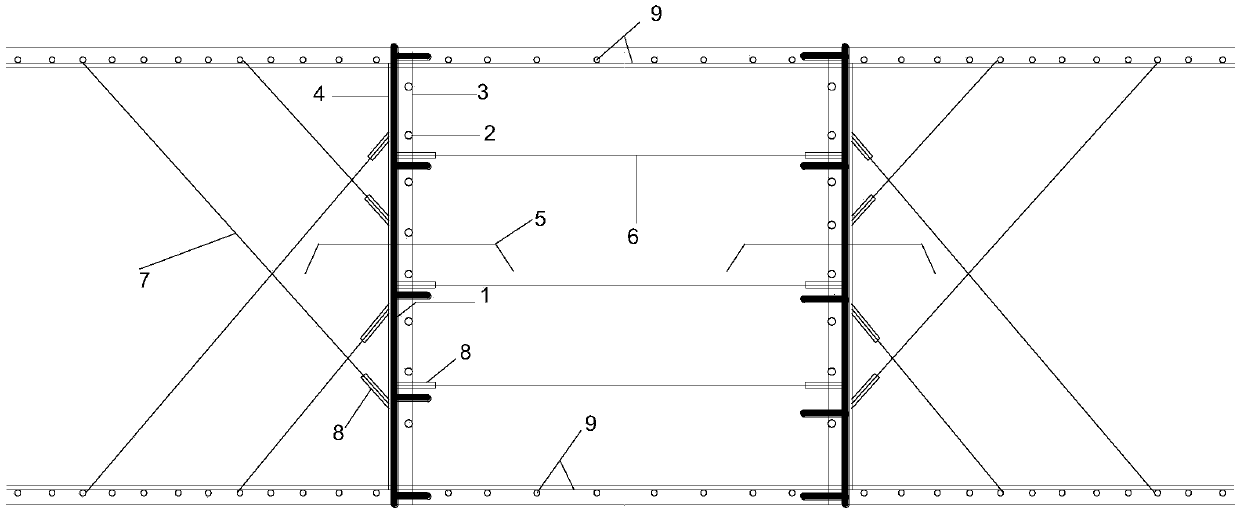

[0034] Such as Figure 1 to Figure 4 As shown, the basement roof pre-closed post-cast belt structure includes: comb-shaped lattice structure 1, diamond-shaped steel mesh 2, steel wire mesh 3, vertical reinforcement steel plate 4, water-stop steel plate 5, horizontal support rod 6, Oblique iron wire brace rod 7, straight thread sleeve 8, post-cast main reinforcement 9, ribbed upper prefabricated plate 10, rib beam 11, connecting screw 12, deformation adjusting gasket 13, lifting screw 14, water stop ring 15. Ribbed lower prefabricated plate 16, pump pipe 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com