Airport apron pipe network constant pressure control system simulation device

A technology of constant pressure control and system simulation, which is applied in electrical program control, program control in sequence/logic controllers, etc., and can solve problems such as difficulty in accurately judging hydraulic characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The simulation device for the ramp pipe network constant pressure control system provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

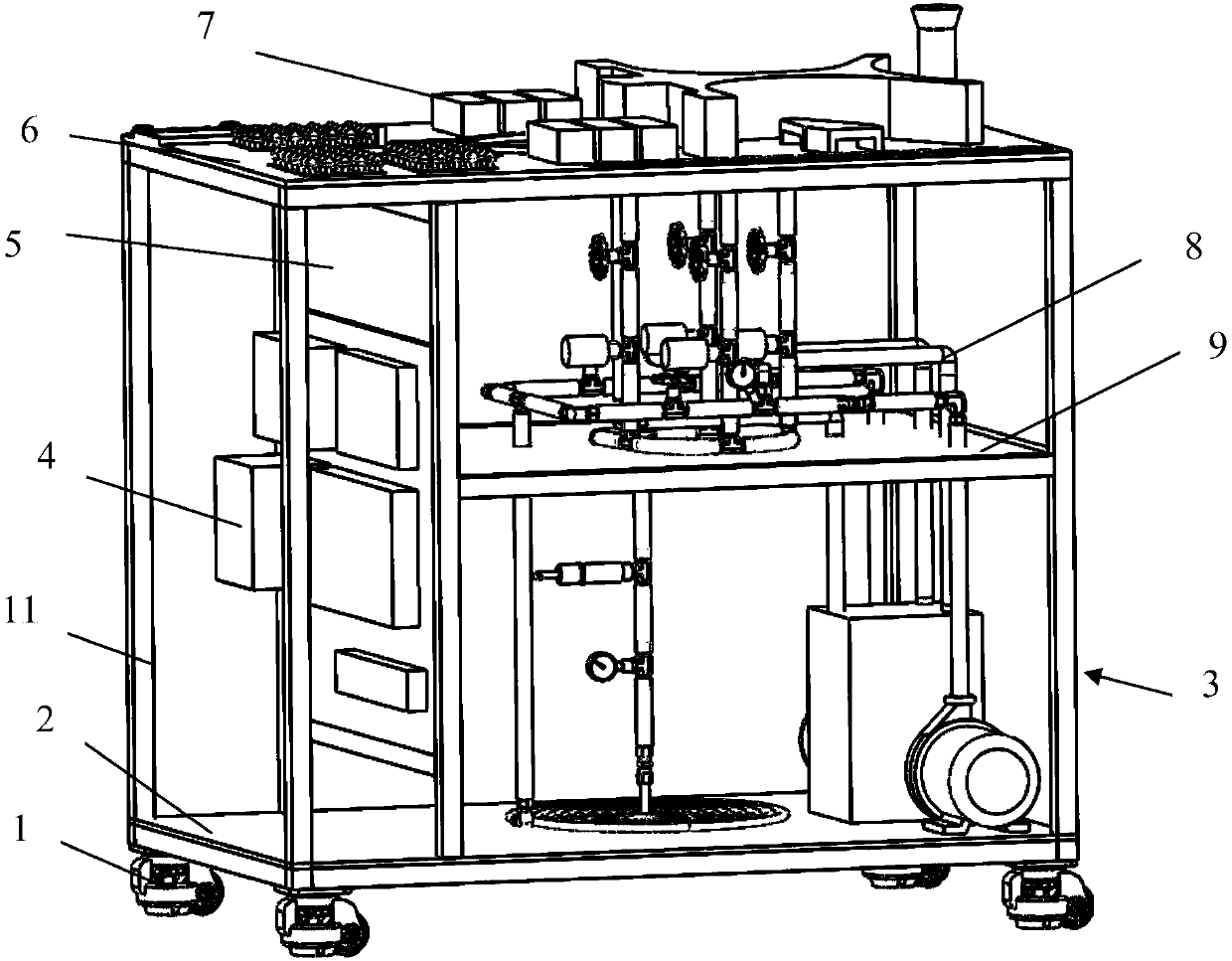

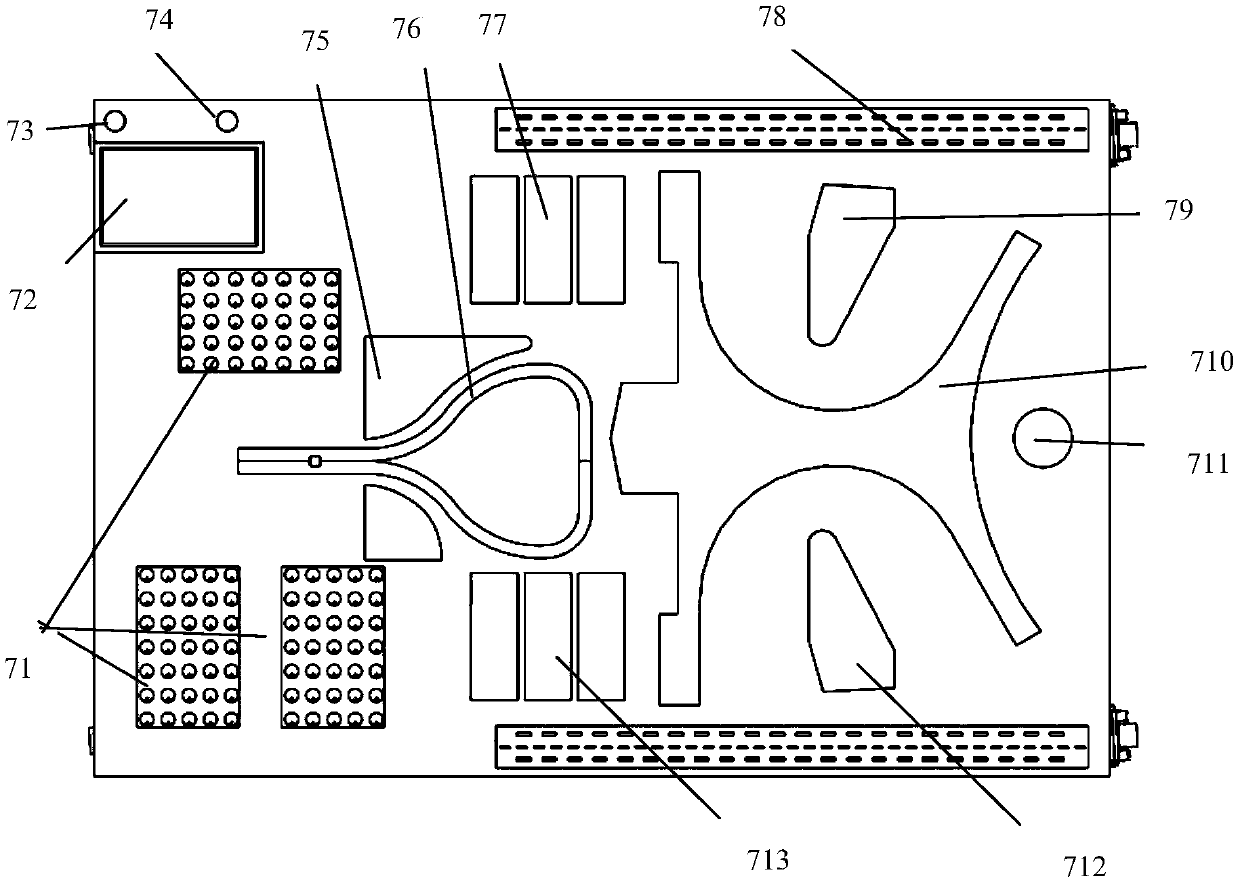

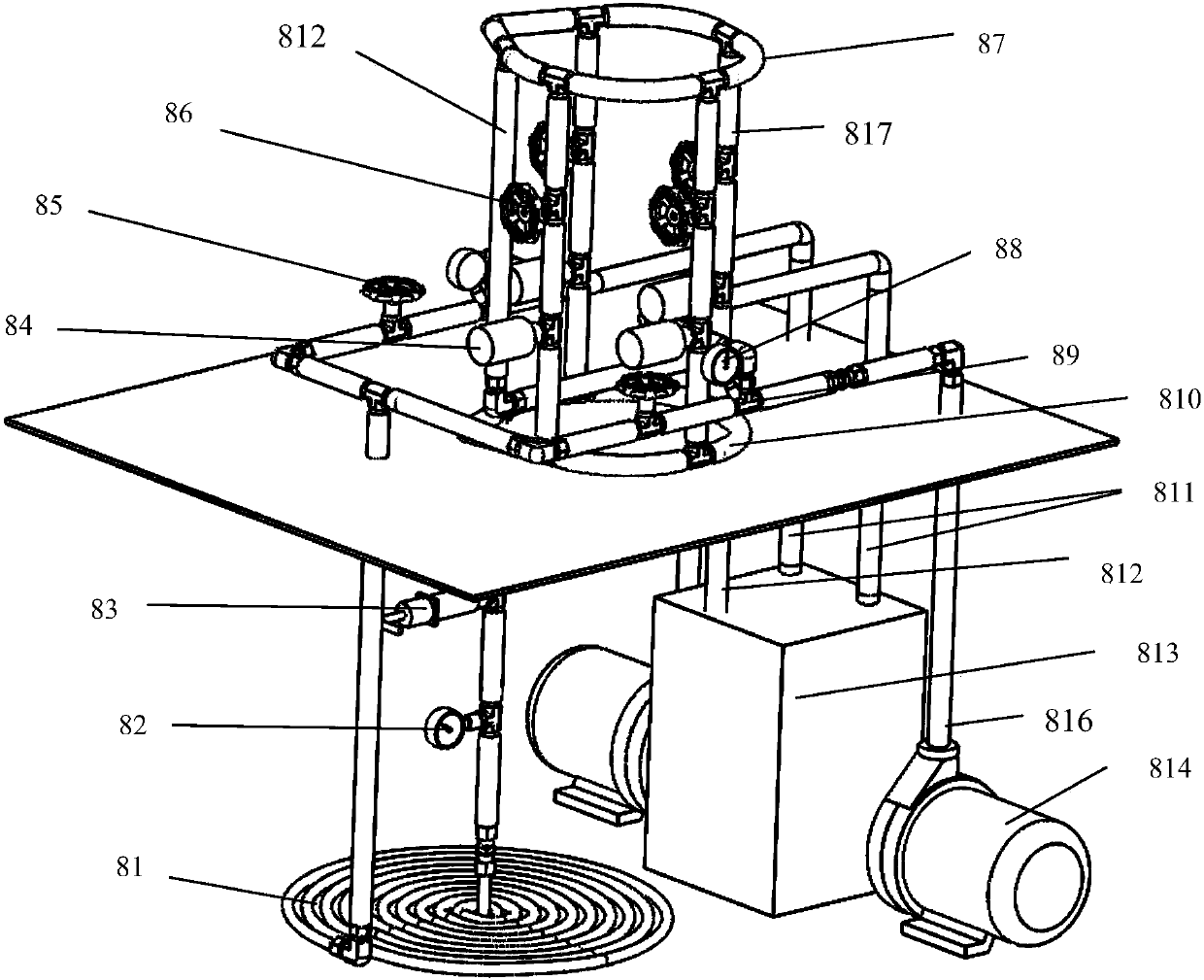

[0023] Such as Figure 1 to Figure 5 As shown, the simulation device of the ramp pipe network constant pressure control system provided by the present invention includes a background computer 10 and a simulation platform; wherein the simulation platform includes: casters 1, frame 3, colorful light system, PLC control system 4, and airport sand table demonstration model 7 and apron pipe network constant pressure liquid supply system 8; the frame 3 includes a base plate 2, a PLC mounting plate 5, a middle plate 9, a top plate 6 and a vertical connecting rod 11; The connecting rod 11 is installed above the bottom plate 2; the PLC mounting plate 5 is vertically arranged, and the upper and lower ends are respectively connected to the bottom surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com