Modular sealing apparatus with failure detection unit

A technology for sealing equipment and fault detection, which is used in protection equipment, metal processing equipment, and by measuring the acceleration and deceleration rates of fluids to increase operation duration, improve reliability and replaceability, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

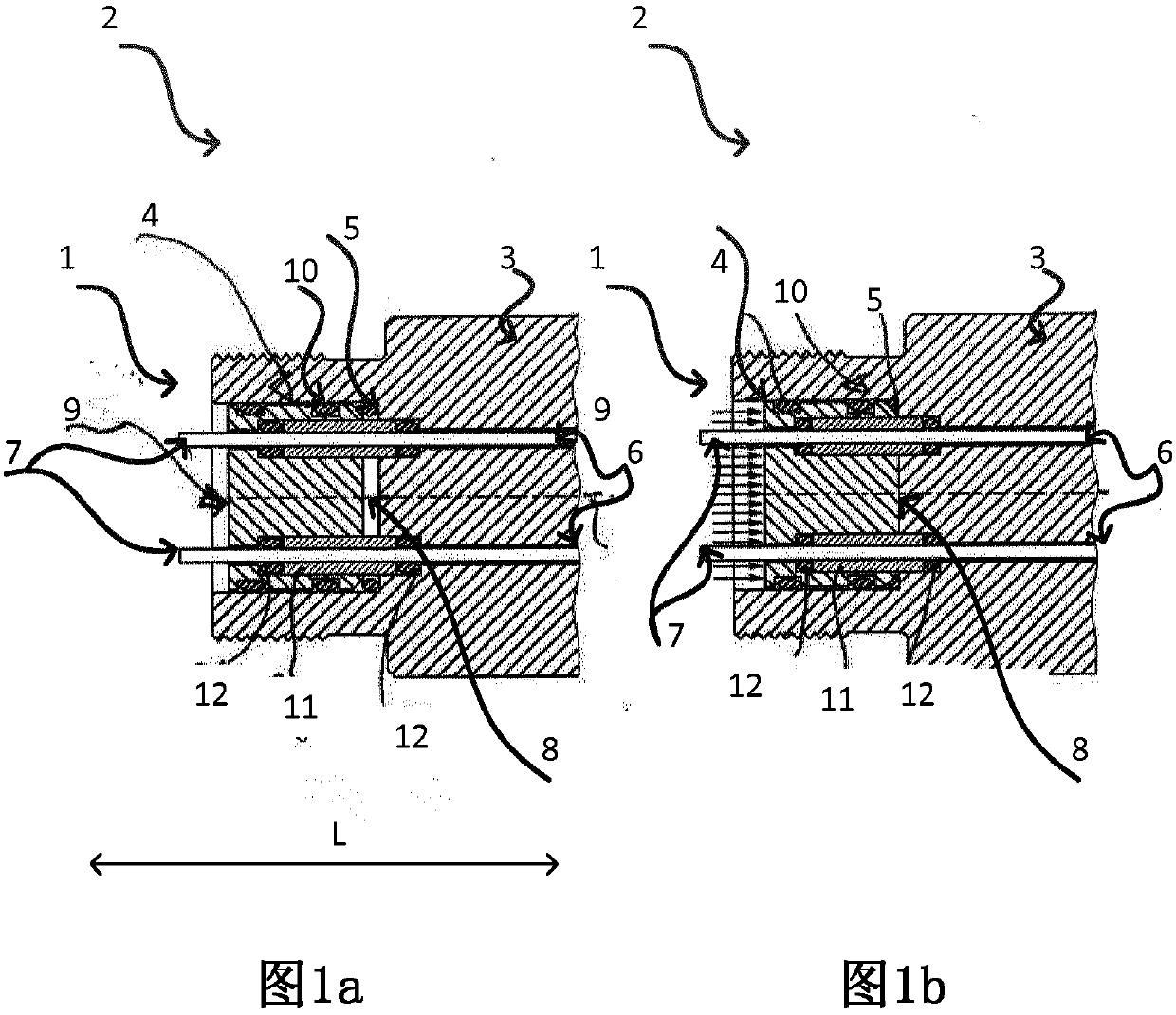

[0047] FIG. 1 shows a schematic representation of a modular sealing device 1 integrated into a mounting assembly 2 according to the prior art described in DE 10 2011 088 736 A1. The mounting assembly 2 is fastened to a process connection 3 , such as a mount on a container such as a tank or pipe, to which the first housing part 4 is connected. Preferably, the first housing part 4 is embodied such that it fits the process connection 3 exactly, such that the transition between the process connection 3 and the first housing part 4 is substantially between the two parts 3, 4 occurs without any offset between them, but instead the two parts 3, 4 may be precisely oriented to fit and preferably aligned relative to each other. Furthermore, on the joint surface A between the first housing part 4 and the process connection 3 a seal 5 , for example an O-ring, can be placed in a recess in the process connection 3 .

[0048] The mounting assembly 2 additionally comprises at least one boreh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com