Threading machine feeding cylinder with cutting structure

A feeding cylinder and wire threading technology, which is applied in the field of wire threading machines, can solve problems such as spark formation, large frame body, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

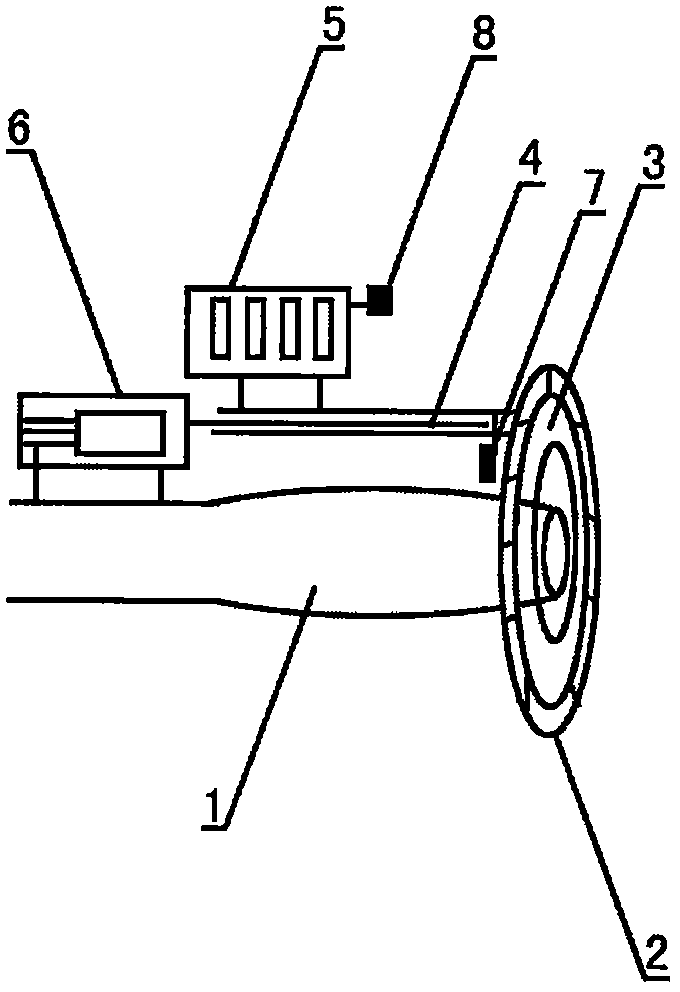

[0012] Embodiment: as shown in the accompanying drawing. The wire threading machine feeding cylinder with its own cutting structure includes a feeding cylinder body (1), and the front end of the cylinder body (1) is equipped with a cutting structure including a circular protective cover device (2) and a zoom cutting device (3). The distance between the support rods (4) is adjusted, and the main control panel (5) is installed on the outer end of the cylinder (1). During operation, the connection device (6) is positioned laterally on the side of the feeding cylinder, and the sensor module (7) is used for threading The operating frequency of the machine is dynamically monitored and the fixed-point position is adjusted to perform scaling cutting.

[0013] The feeding barrel of the wire threading machine with its own cutting structure is equipped with a prompting device (8), and a corresponding prompt is issued when the wire threading machine completes the equal-length threading op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com