Protective cover for a lathe

A protective cover and lathe technology, which is applied in the direction of maintenance and safety accessories, metal processing equipment, metal processing machinery parts, etc., can solve the problem of inability to adjust the height of the protective cover of the lathe, affect the sanitary environment of the protective cover of the lathe, and cannot clean the protective cover of the lathe Dirt and other problems, to achieve the effect of favorable operation, practical function and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

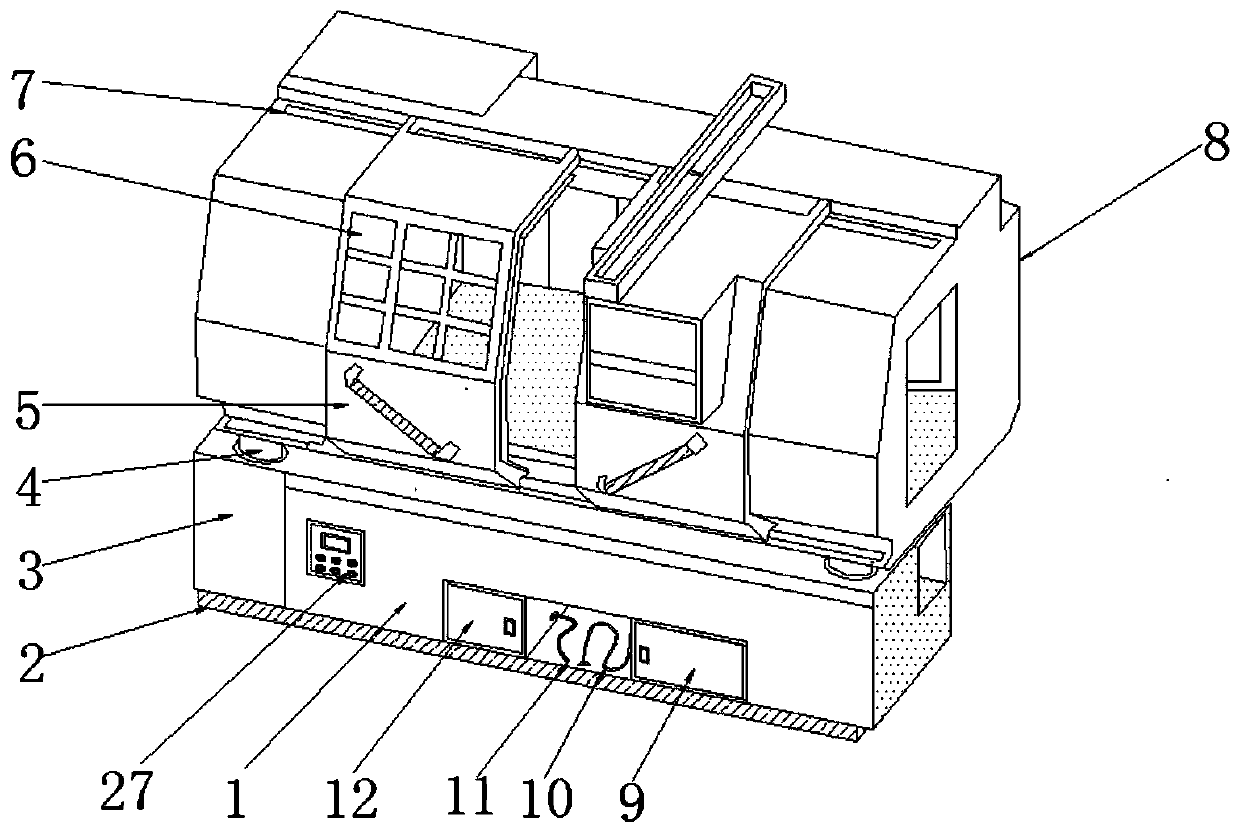

[0023] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a lathe protective cover, including a lathe protective cover body 1, a shock absorbing plate 2, a base 3, a first hydraulic lifting rod 4, a sliding door 5, an observation window 6, and a slide rail 7. Upper cover 8, dust collection box 9, dust suction port 10, nozzle 11, cleaning box 12, telescopic rod groove 13, handle 14, dust bag 15, filter screen 16, motor 17, air outlet 18, support rod 19, Fan blade 20, pressure frame 21, pulley 22, base plate 23, second hydraulic lifting rod 24, water tank 25, water pipe 26, control switch 27, fixed plate 28, water pump 29 and water inlet 30, lathe protective cover body 1 upper end setting There is an upper cover 8, and the lower end of the lathe protective cover body 1 is provided with a base 3, and the bottom end of the lathe protective cover body 1 is provided with a damping plate 2, and the lower end of the lathe protective cover body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com