Quick locking substrate of section aluminum assembly machine

A technology for positioning bases and aluminum profiles, applied to conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as insufficient self-regulation and long time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

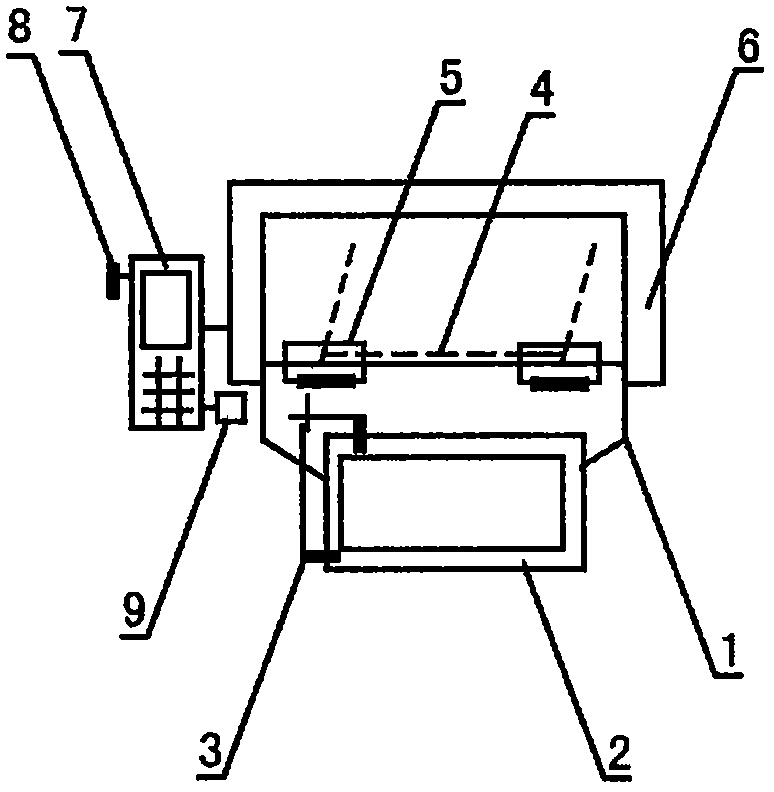

[0012] Embodiment: as shown in the accompanying drawing. The quick positioning base of the aluminum profile threading machine includes a frame body (1), the frame body (1) has a two-part structure design, and the front end is equipped with measuring components including a nozzle support frame (2), a movable measuring device (3) , the rear end is provided with a guide track (4), a positioning adjustment base block (5), a push device (6), a display device (7) is located on the side of the frame body (1), and the frame body (1) is positioned on the strip threading machine during operation At the inlet end, when the aluminum profile is placed horizontally on the conveyor table, it will be quickly positioned and guided by measuring the appearance of the component.

[0013] The quick positioning base of the aluminum profile threading machine is equipped with a prompting device (8), and the prompting information is displayed by sound or LED light.

[0014] The rapid positioning base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com