Self-fastening fabric

A velcro and fabric technology, applied in the direction of fabric and fabric surface trimming, knitting, etc., can solve the problems of losing the velcro function and reducing the velcro function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

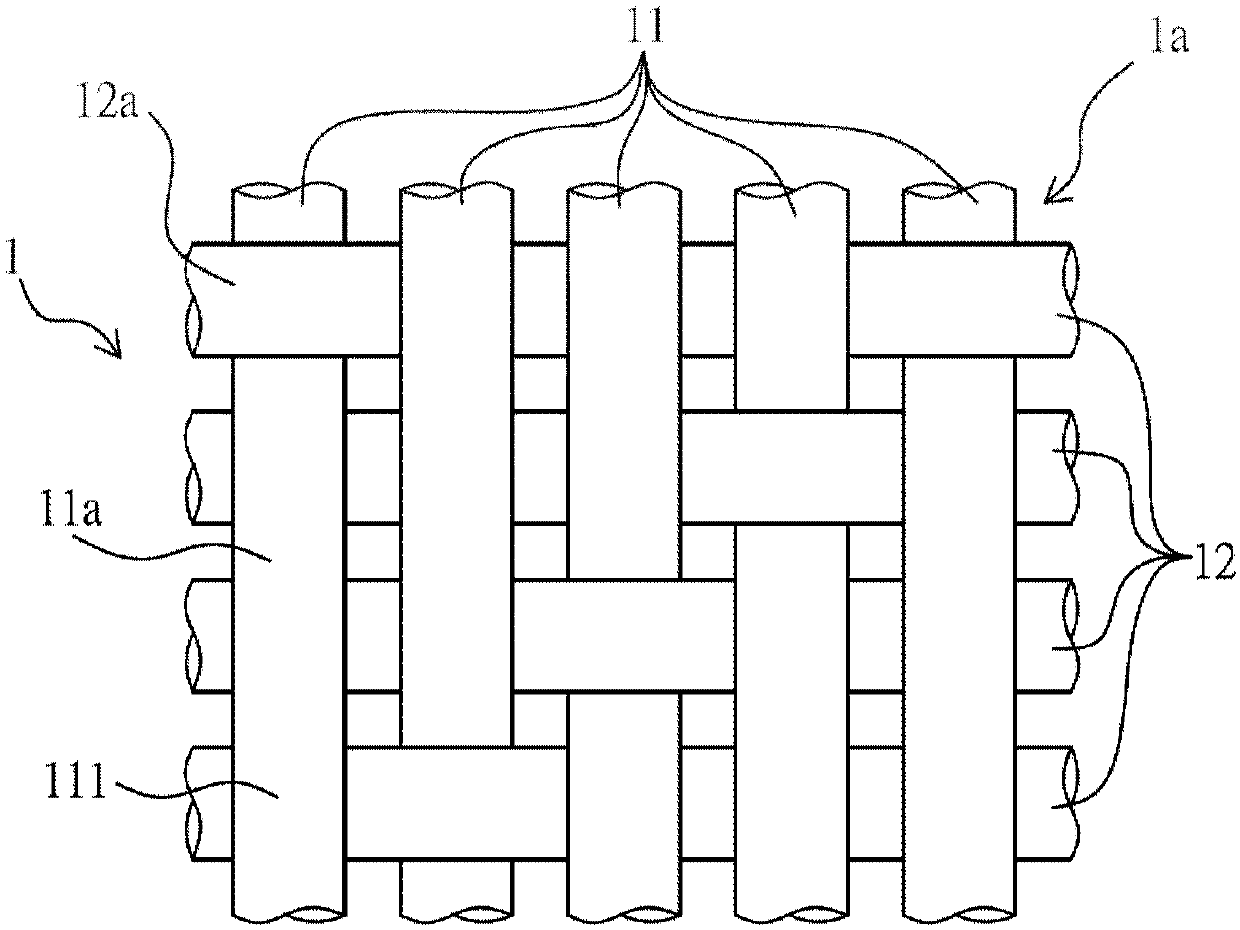

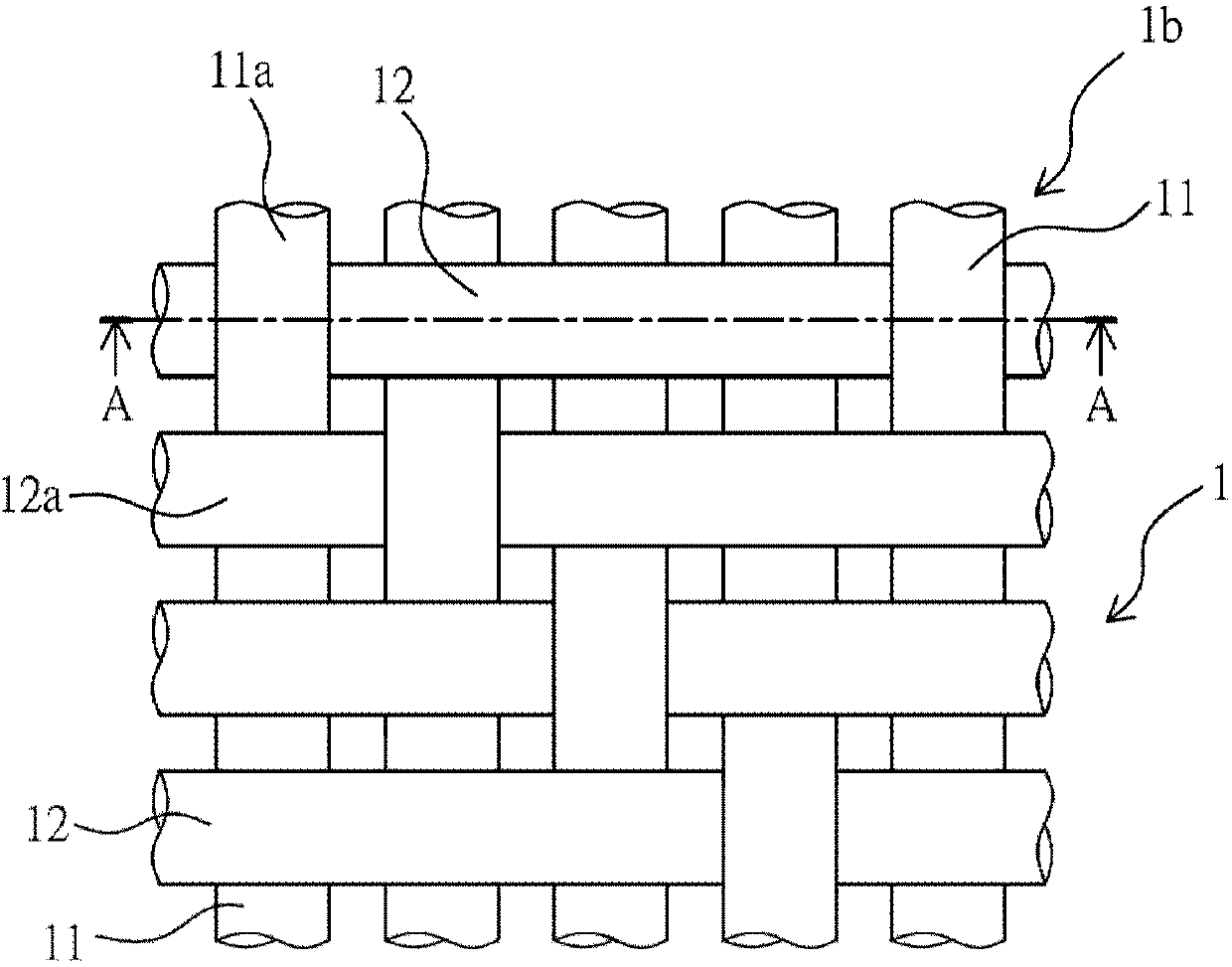

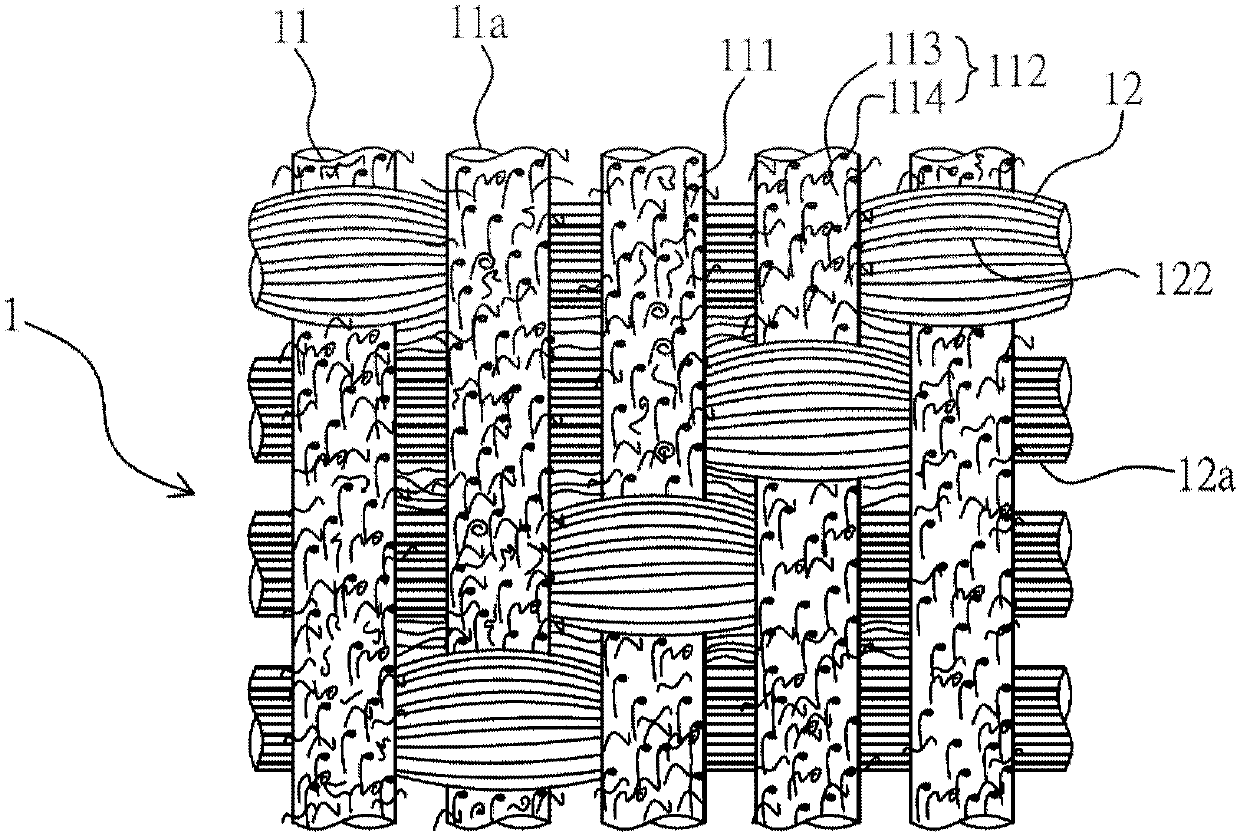

[0019] Basically, as in figure 1 Shown is a first embodiment of a self-gluing fabric 1, the self-gluing fabric 1 is a 3 / 1 warp-faced twill (3 / 1 warp-faced twill) structure woven by a shuttle loom. The warp yarn 11a of the hook and loop fabric 1 includes at least one heat-melt fiber yarn 111 , and the weft yarn 12a includes at least one heat-shrinkable fiber yarn 121 . A first surface 1 a of the 3 / 1 warp twill weave serves as the hook weave 11 , and a second surface 1 b serves as the loop weave 12 . Observing from this first side 1a of this self-gluing fastening fabric 1, it shows a kind of 3 / 1 warp face twill weave, and the floating number of these warp yarns 11a is 3 times of these weft yarns 12a; Now this first side 1a serves as A hook tissue surface. Therefore, the area occupied by the hook structure 11 on the first surface 1 a is three times that of the ring structure 12 . Therefore, after the 3 / 1 warp face twill weave, most of the heat-melt fiber yarn 111 appears on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com