Fatigue test fixture

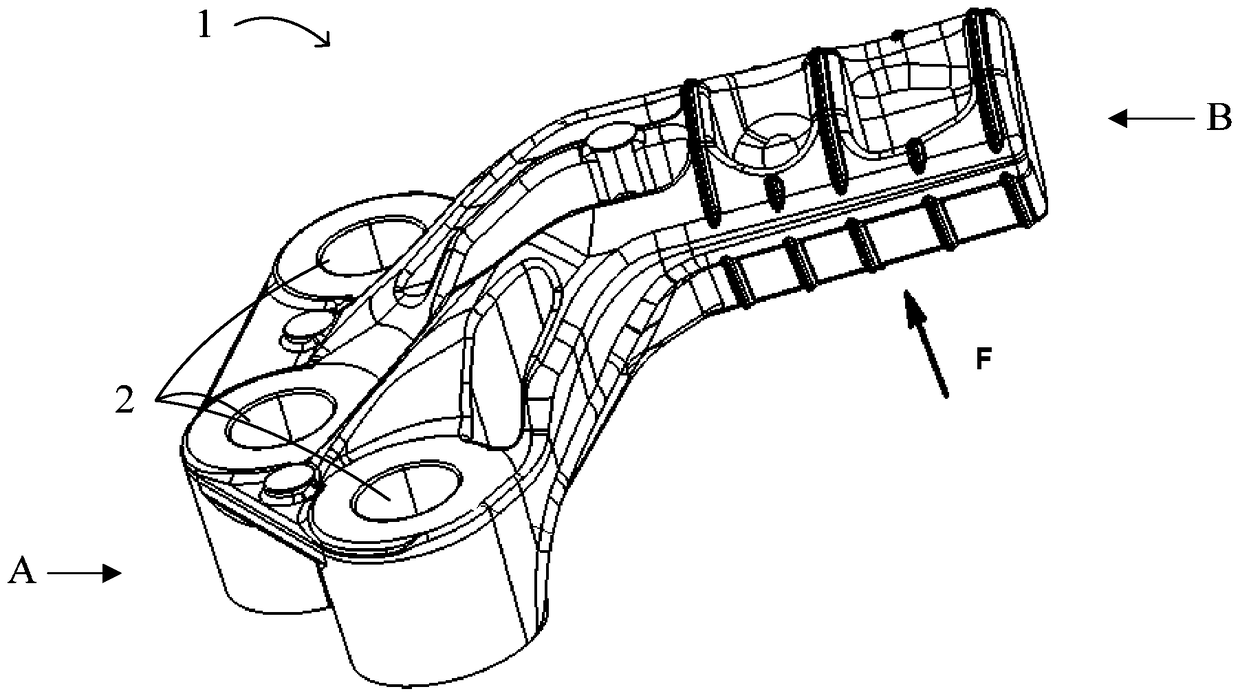

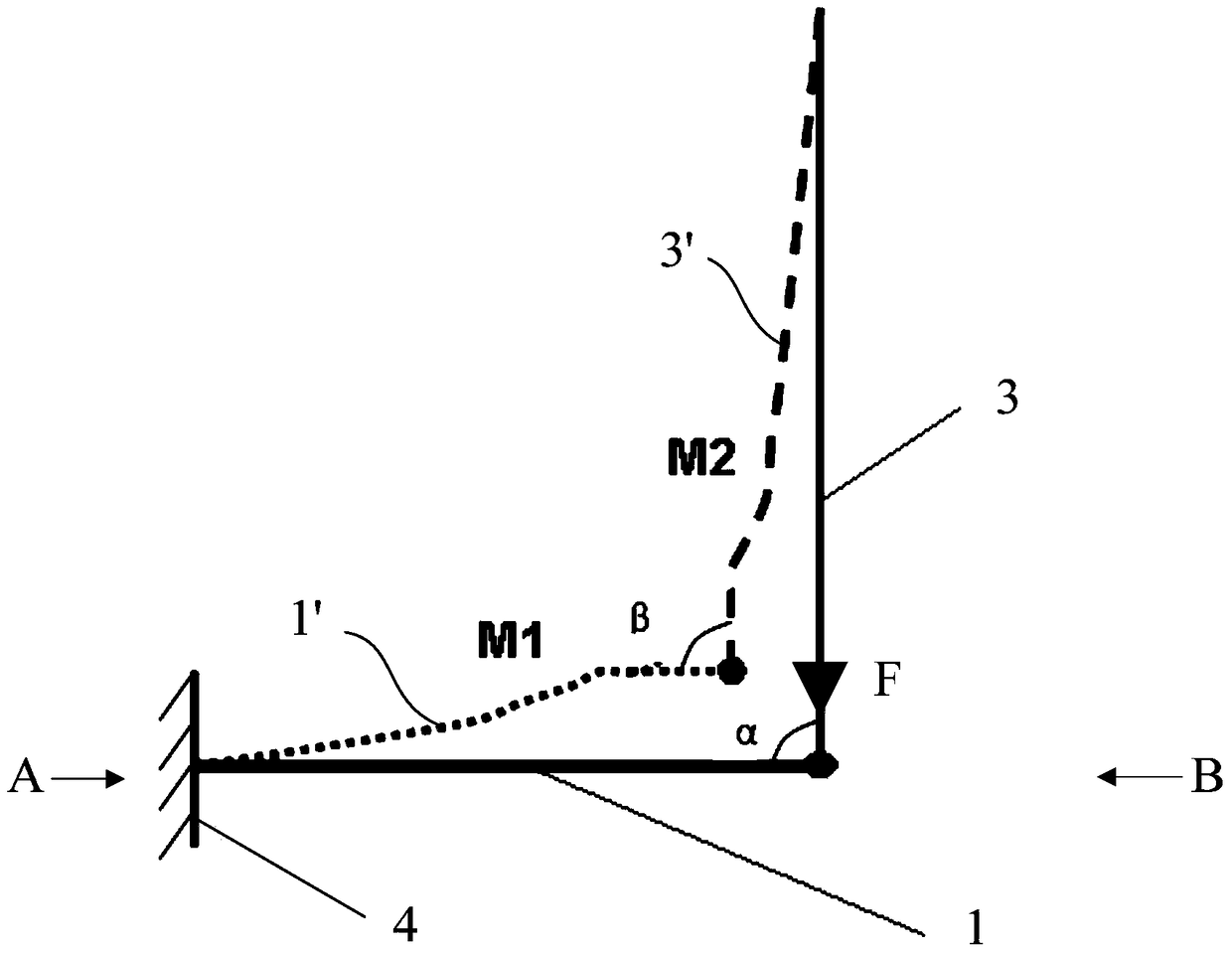

A fatigue test and fixture technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of damage to the force application equipment, accurately predict the fatigue life of the suspension arm 1, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

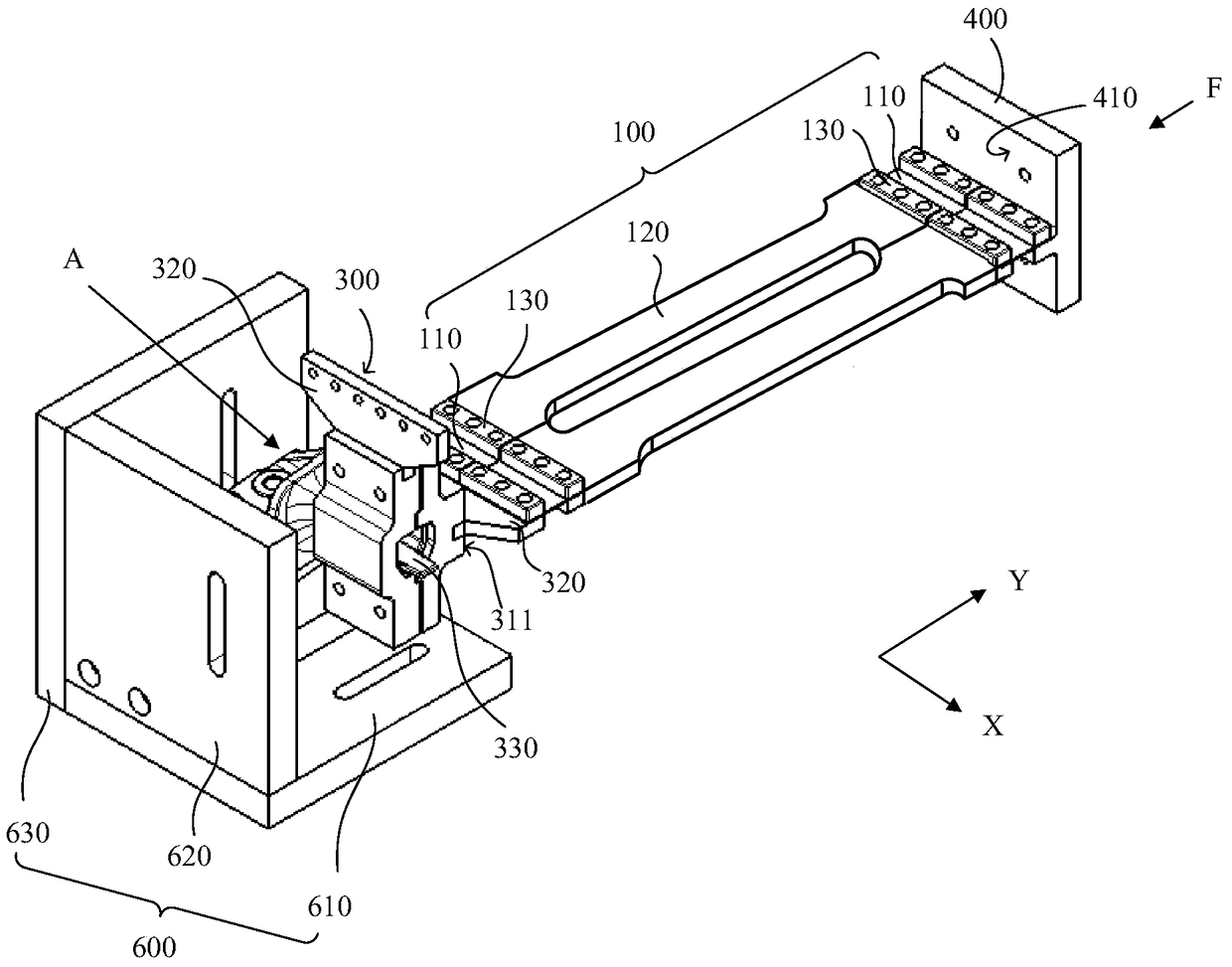

[0044] This embodiment provides a kind of fatigue test fixture, with reference to image 3 shown, including:

[0045] The clamping part 300 is formed with a clamping groove 330, and the clamping groove 330 has a side wall 340 extending along a first direction X, wherein the first direction X is perpendicular to the force direction F of the clamp during the test; the clamping part 300 For clamping the force-bearing end of the test part A, specifically, the force-bearing end of the test part A is clamped in the slot 330;

[0046] The coupling part 400 has a coupling surface 410; the coupling part 400 is used to connect a force applying device (not shown in the figure), such as a hydraulic servo actuator, etc., and the force applied by the force applying device is transmitted to the coupling surface 410 of the coupling part 400 , and then passed to the clamping part 300;

[0047] The first spring steel sheet group 100 is connected between the side wall 311 of the clamping part ...

no. 2 example

[0059] The difference between this embodiment and the above-mentioned embodiment is that, if Figure 5-6 As shown, the fatigue test fixture of this embodiment includes two first spring steel sheet groups 100, and also includes a second spring steel sheet group 200;

[0060] The second spring steel sheet group 200 includes two second spring steel sheets 210, and the second spring steel sheets 210 are perpendicular to the first spring steel sheets 110;

[0061] Two sets of first spring steel sheet groups 100 and the second spring steel sheet group 200 are connected in a staggered manner along the second direction Y, that is, the second spring steel sheet group 200 is connected to the above two groups of first spring sheets along the second direction Y. Between 100 steel sheet groups.

[0062] In this embodiment, each group of first spring steel sheets 100 includes a first spring steel sheet 110; the second spring steel sheet group 200 is a group, which includes two second sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com