High-reliability multi-stage vibration reduction auxiliary support device, gearbox assembly and truck

A technology of auxiliary support and gearbox, which is applied in the field of vehicle parts, can solve the problems of reducing the reliability of rubber suspension blocks, is not conducive to the lightweight design of the whole vehicle, and limits the freedom of auxiliary supports, so as to improve the service life and ride comfort performance, avoid beam breakage, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific examples.

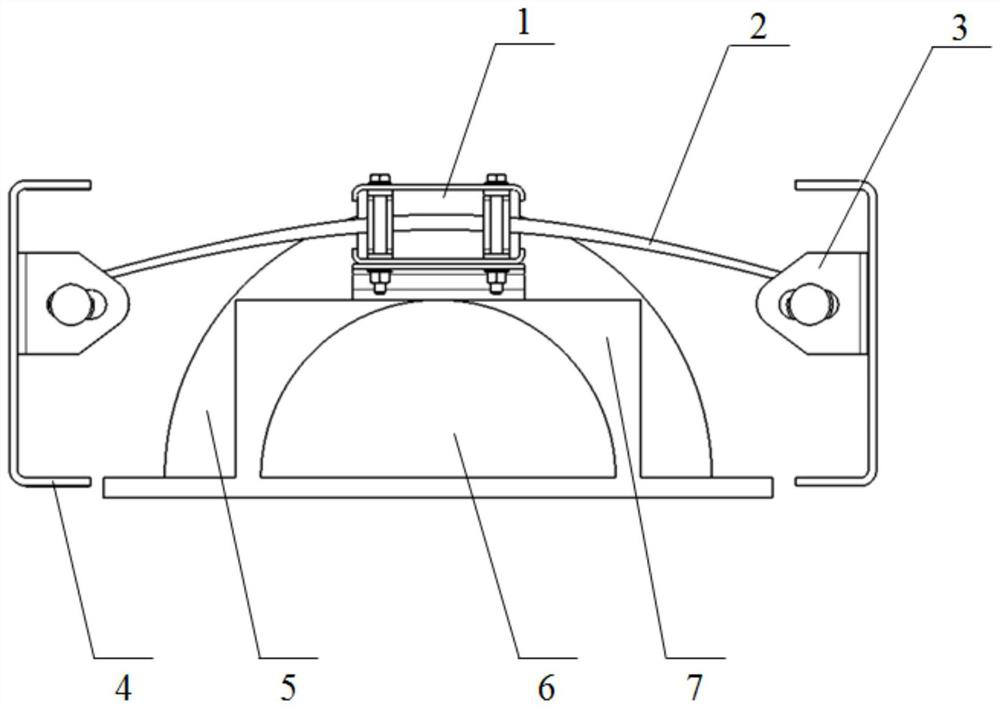

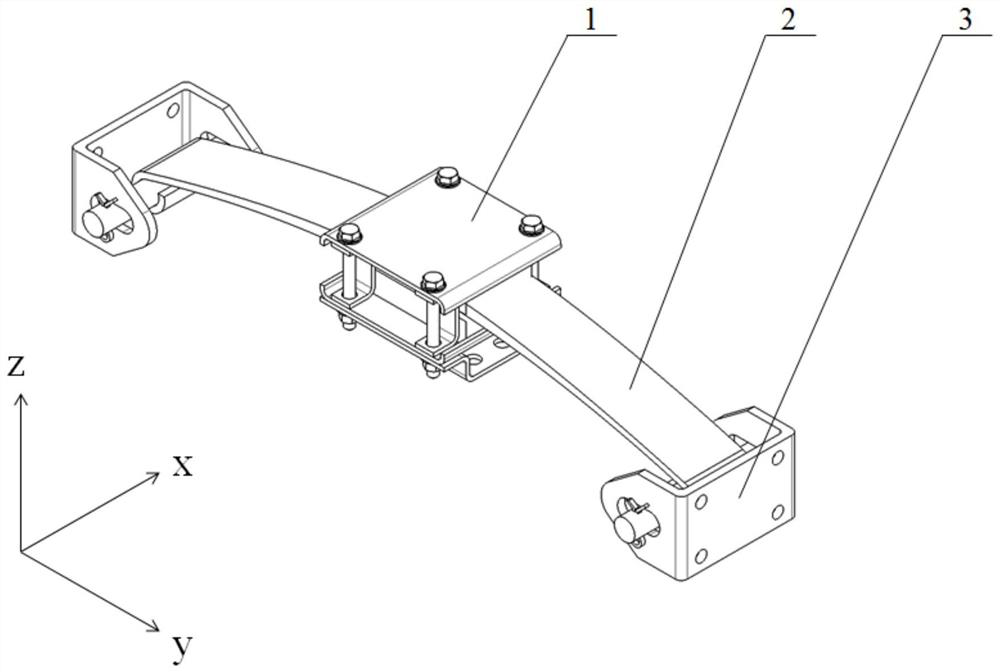

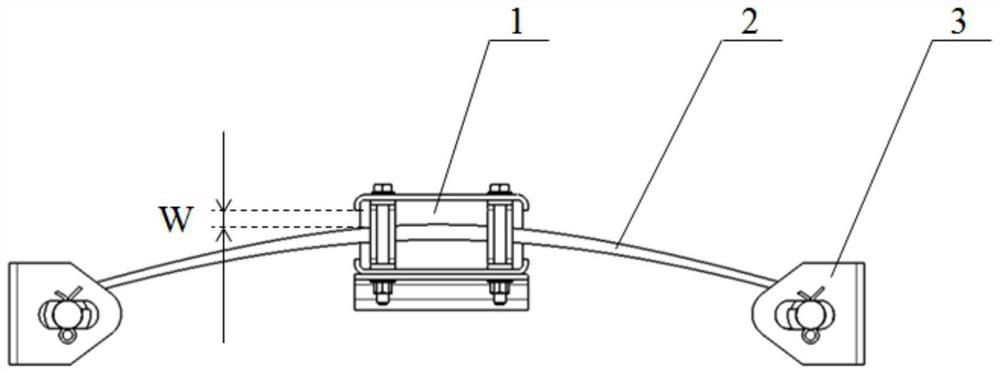

[0034] Such as Figure 1-Figure 3 As shown, it is a high-reliability multi-stage vibration reduction auxiliary support device, including a rubber suspension module 1, a variable-section leaf spring 2, and a bracket assembly 3. The rubber suspension module 1 is fixedly connected to the gearbox 6, and the bracket The assembly 3 is fixedly connected to the vehicle frame 4, the variable-section leaf spring 2 passes between the upper rubber cushion 12 and the lower rubber cushion 13 of the rubber suspension module 1, and the variable-section leaf spring 2 has ears at both ends. It is slidably connected with the bracket assembly 3 through a pin 31 .

[0035] Such as Figure 4 As shown, the rubber suspension module 1 includes an upper metal cover plate 11, an upper rubber cushion 12, a lower rubber cushion 13, a lower metal cover plate 14, a mounting plate 15, a suspension bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com