Processing process of fuel filter element

A technology of fuel filter element and processing technology, which is applied in the field of processing technology of fuel filter element, can solve the problems of affecting power effect, reduction of pump oil pressure, wrinkles, etc., and achieves good effect and smooth filter hole effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

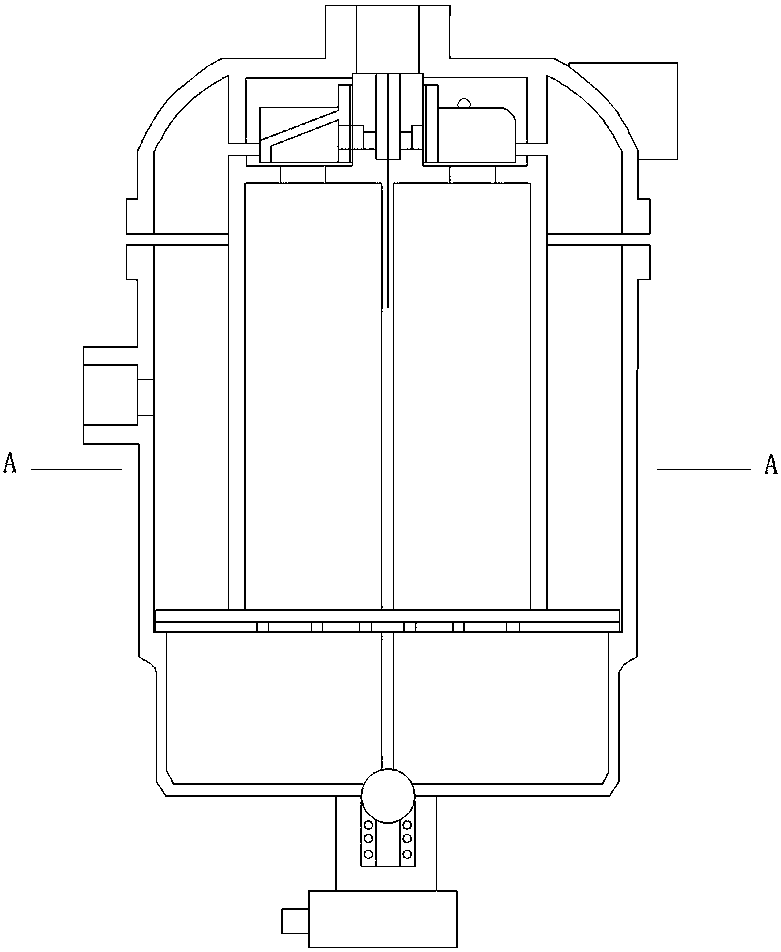

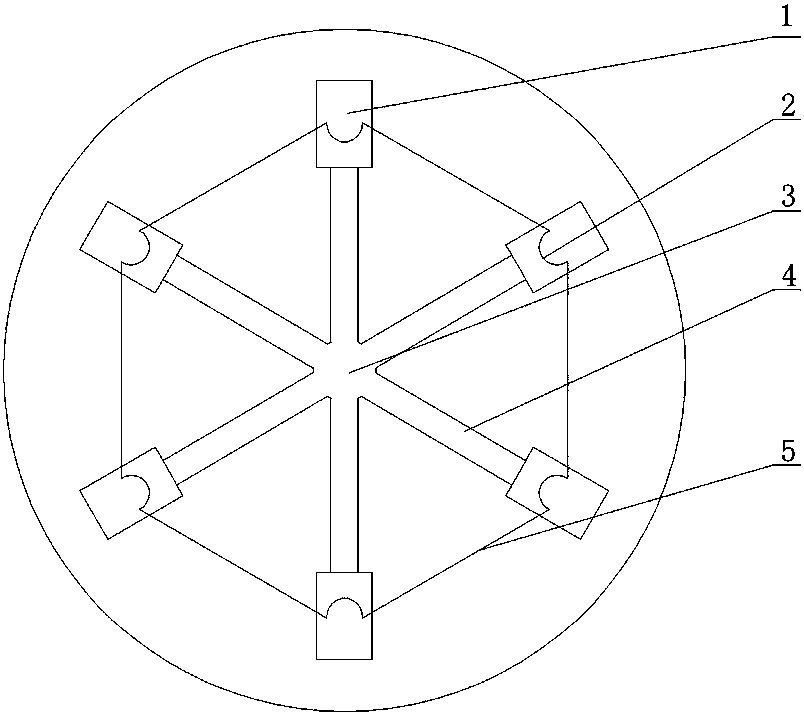

[0010] In the processing technology of the fuel filter element of the present invention, the fuel filter element includes a support frame, a protection frame 1 and a filter screen 5, and the end of the support frame is provided with a concave groove 2 to connect the filter screen 5 After being sleeved on the support frame, the protective frame 1 is connected to the support frame by injection molding, so that the filter screen 5 sinks into the groove 2 to form an integral filter element with a flat screen surface. The supporting frame is composed of a main body 3 and a radiating plate 4, the radiating plates 4 are evenly distributed on the main body 3, and the concave groove 2 is provided at the end of the radiating plate 4. When injection molding is performed on the groove 2, the filter screen 5 is simultaneously plunged into the groove 2, and the filter screen 5 is tightened. Without wrinkles, the pressure of the oil pump is not reduced due to the wrinkles of the filter screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com