Electronic candle

A technology for electronic candles and circuit boards, which is applied to electric light sources, circuit layouts, lighting devices, etc., can solve the problems of reduced assembly efficiency, easy to break wires, and circuit board de-soldering, etc., to facilitate manual assembly and avoid tearing. , the effect of small contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

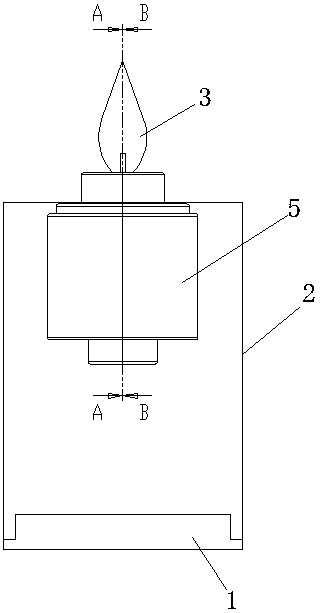

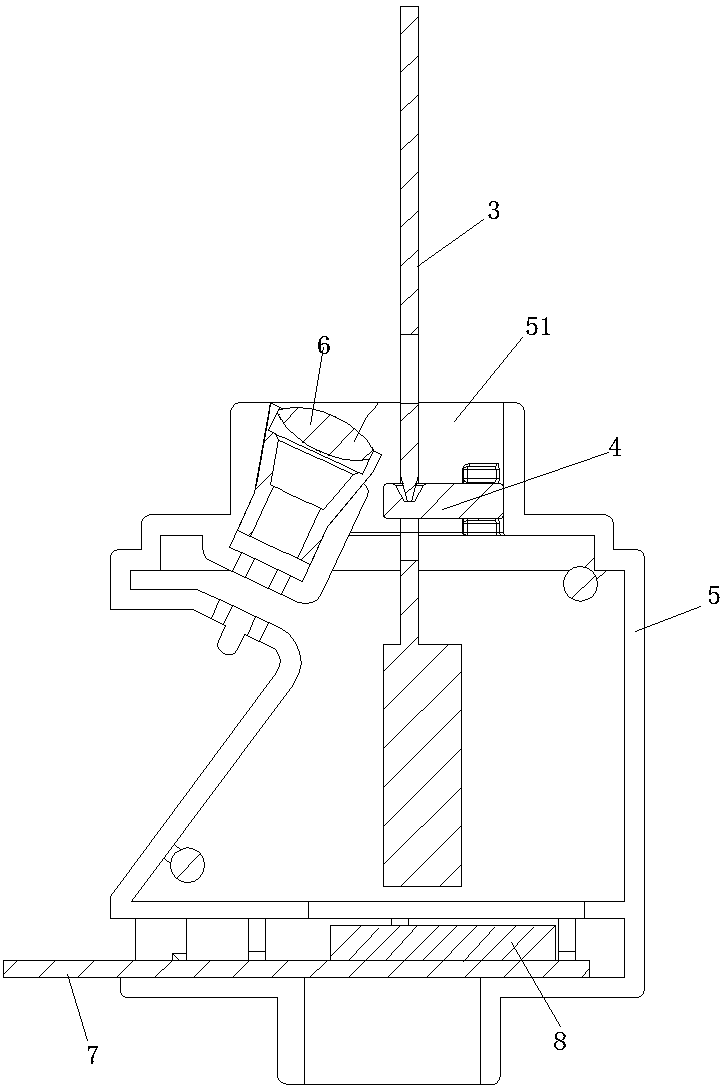

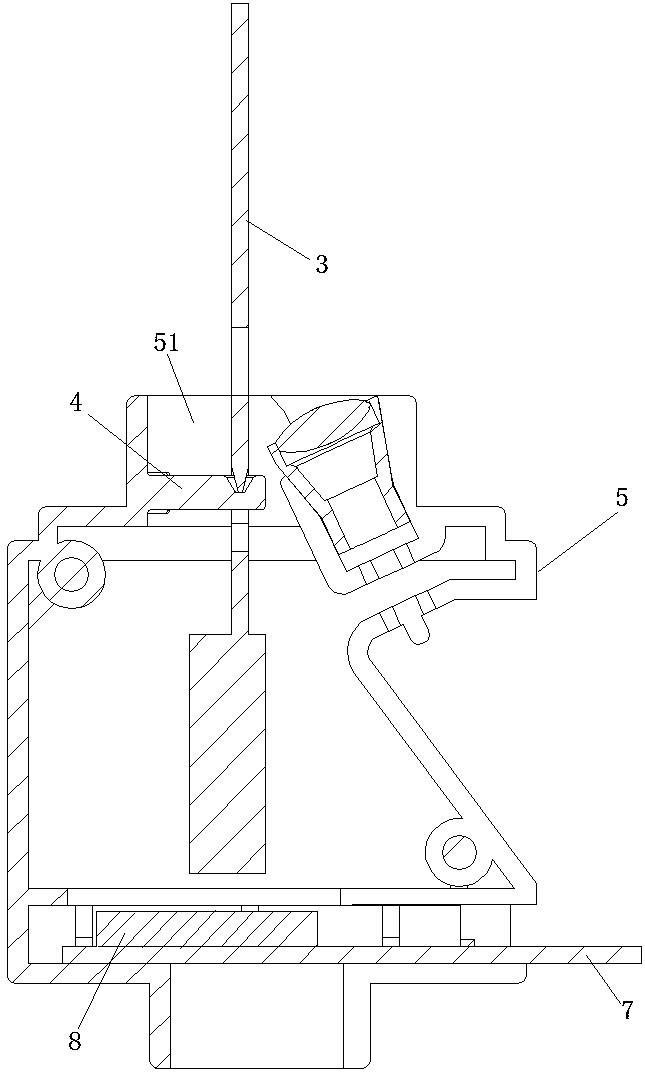

[0033] Such as Figure 1-9 As shown, an electronic candle includes a base 1, a hollow housing 2 installed on the base 1, a first through hole 21 arranged on the top of the housing 2, a flame sheet 3, a flame sheet support 4, and a A hollow mounting seat 5 in the inner cavity of the body 2, a light-emitting element 6 and a circuit board 7 installed on the mounting seat 5.

[0034] The top of the mounting base 5 is provided with a second through hole 51 , and the top of the mounting base 5 is assembled and fixed with the first through hole 21 . The lower part of the mounting base 5 is provided with a card slot 52 .

[0035] The flame sheet support 4 is integrally formed with the mounting seat 5 , and the flame sheet support 4 includes a horizontal cantilever seat 41 fixedly connected to the inner wall of the second through hole 51 . The front end of the cantilever seat 41 is provided with a groove 42, and the bottom of the groove 42 is a plane.

[0036] The flame sheet 3 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com