Position detection device and method for steel roll system

A detection device and detection method technology, applied in the direction of measurement device, measurement instrument, surveying and mapping, and navigation, can solve the problems of imperfect design of measurement device and data processing algorithm, and achieve fast data processing speed, convenient assembly and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

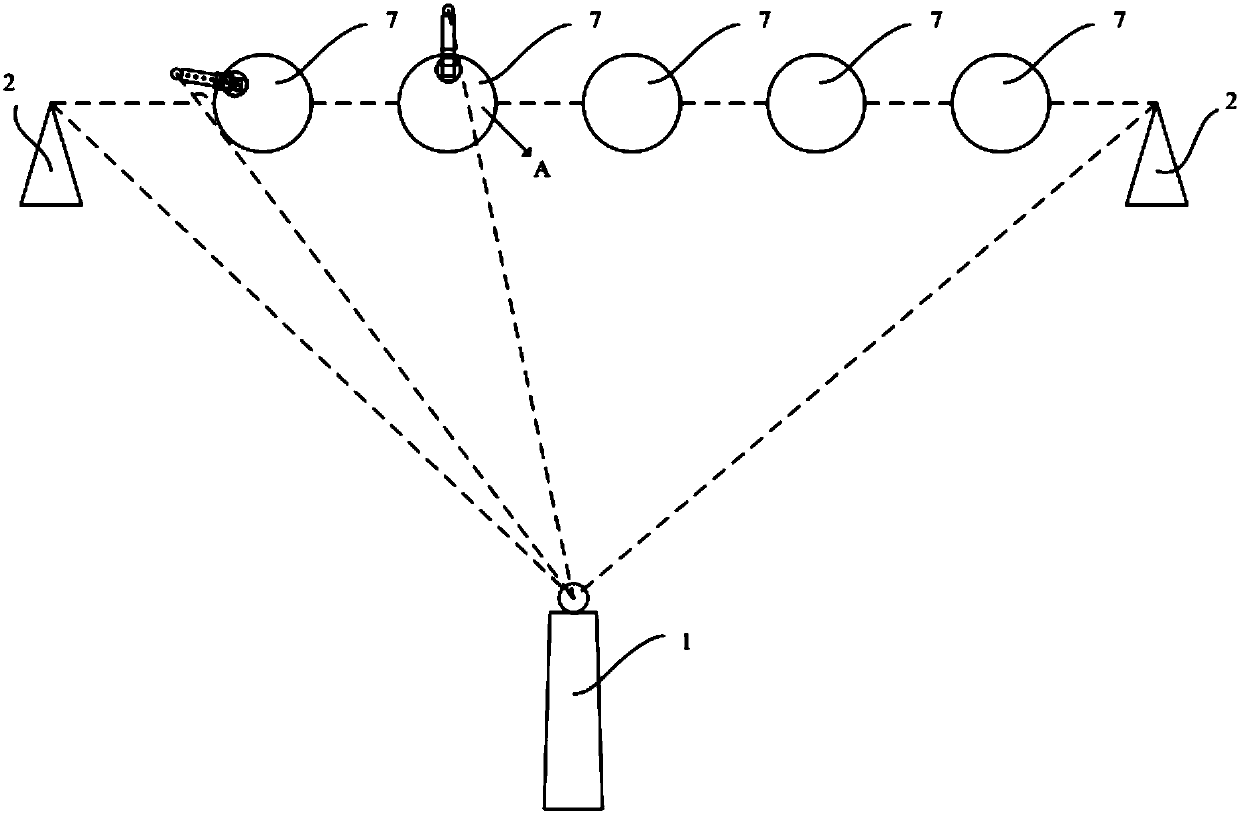

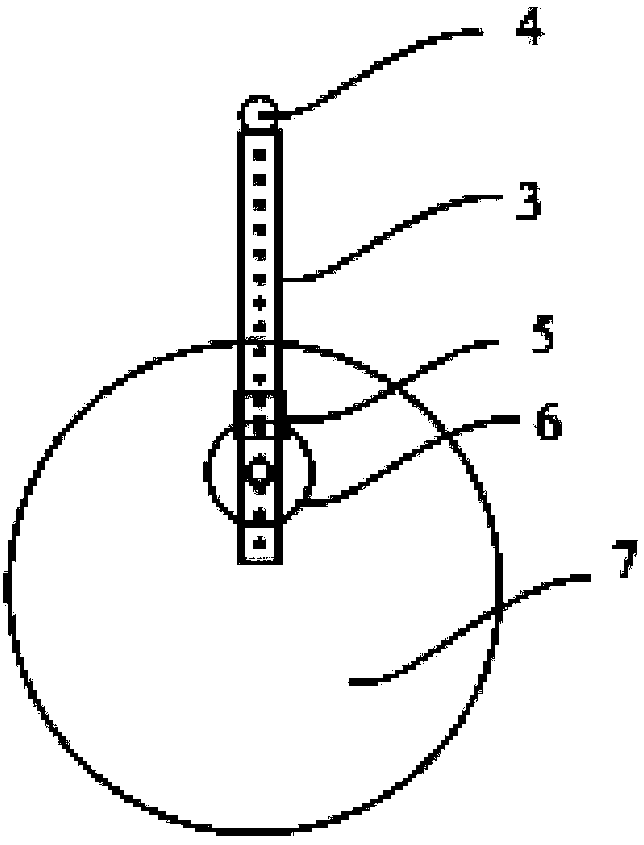

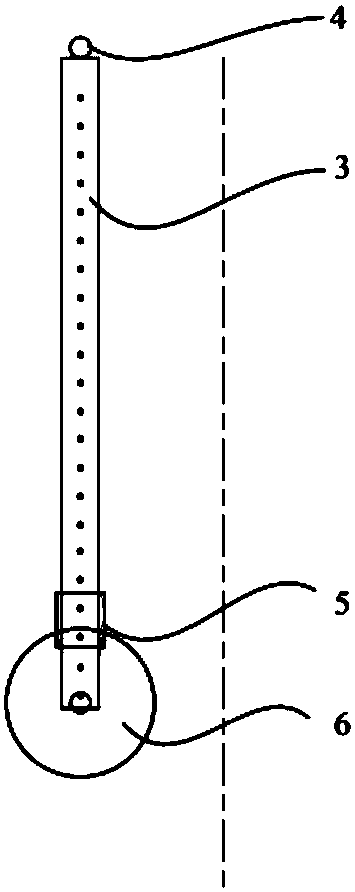

[0060] like Figure 1-5 As shown, the present invention discloses a steel roller system position detection device, the device includes a total station 1, a reference landmark 2 and a benchmark, the benchmark includes a benchmark arm 3, a prism 4, a slider 5 and a vacuum suction cup 6, the total station 1 is erected on the left and right sides of the roller system and on the side of the two reference landmarks 2, and the specific measurement position is adjusted according to the actual operation. The spherical prism 4 is fixedly connected to the top of the benchmark 3, and can be fixedly connected through screw holes. The total station 1 is used to obtain the roll to be tested 7 The coordinates of the center position of the prism 4 when the end surface rotates meet the requirements that the center of the prism 4 can be aligned when all the benc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com