Online detecting device for liquid flow of gas-liquid mixture

A gas-liquid mixture, liquid flow technology, applied in the direction of volume/mass flow generated by mechanical effects, dynamic effects by detecting fluid flow, etc., can solve problems such as inability to accurately measure liquid flow, and achieve simple measurement principles and accurate measurement results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

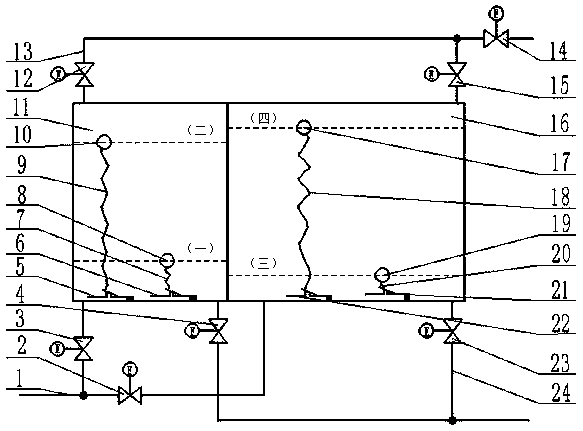

[0018] The present invention will be further described below in conjunction with the drawings.

[0019] Such as figure 1 As shown, a gas-liquid mixture liquid flow online detection device of the present invention includes a liquid inlet pipe (1), a second valve (2), a first valve (3), a third valve (4), and a second switch (5) , The first switch (6), the first flexible rope (7), the first floating ball (8), the second flexible rope (9), the second floating ball (10), the detection fuel tank (11), the fifth valve ( 12), exhaust pipe (13), seventh valve (14), sixth valve (15), auxiliary fuel tank (16), fourth float (17), fourth flexible rope (18), third float (19), the third flexible cord (20), the third switch (21), the fourth switch (22), the fourth valve (23), and the drain pipe (24).

[0020] The first valve 3 is installed on the branch pipe from the liquid inlet pipe 1 to the detection oil tank 11, and the second valve 2 is installed on the branch pipe from the liquid inlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com