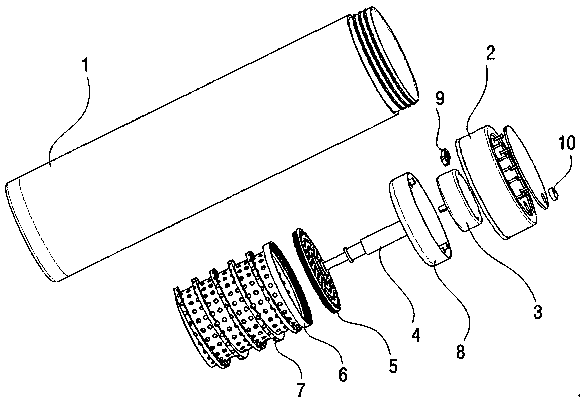

Cup cover spiral stirring type defluorination filtering cup

A technology of spiral stirring and cup cover, which is applied in the direction of filtration treatment, drinking water utensils, water pollutants, etc., can solve problems such as skeletal fluorosis, and achieve the effect of improving the effect and improving the effect of water body filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

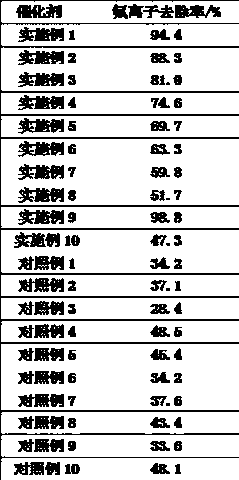

Embodiment 1

[0022] A method for preparing a fluoride-removing filter material, the method comprising the following steps:

[0023] Step 1. Put 2kg of NDA900 type resin raw materials into the filter car, add 2kg of methanol solution, stir intermittently at 45°C, let it stand for 1 hour, then filter out the methanol solution by gravity filtration, return the filtered methanol solution to the distillation system for distillation and repeat Use; then the resin is transferred to a vacuum dryer, heated to 60°C with a water bath, while maintaining a vacuum of 0.2MPa, and unloaded when the water content is reduced to 15%, to obtain a cleaned NDA900 resin; step 2, in Add 2Kg anhydrous FeCl to the 6L reactor 3 and 20% hydrochloric acid to make 3LFeCl 3 solution, wherein the equivalent iron weight content is 10%, and the pH value is 2; the NDA900 type resin after washing, drying and pretreatment is added in batches at a feeding rate of no more than 1 / 10 of the resin addition amount within 15 minute...

Embodiment 2

[0025] Step 2, add 2Kg anhydrous FeCl in 6L reactor 3 and 20% hydrochloric acid to make 3LFeCl 3 solution, wherein the equivalent iron weight content is 10%, and the pH value is 2; the NDA900 type resin after washing, drying and pretreatment is added in batches at a feeding rate of no more than 1 / 10 of the resin addition amount within 15 minutes. 3 In the reaction kettle of the solution, NDA900 type resin and FeCl 3 The solid-to-liquid weight ratio of the solution is 1:1. At 35°C, keep stirring for 2 hours to prepare the FeCl-loaded 4 - Strongly basic anion resin intermediate; All the other steps are with embodiment 1.

Embodiment 3

[0027] Step 2, add 2Kg anhydrous FeCl in 6L reactor 3 and 20% hydrochloric acid to make 3LFeCl 3 solution, wherein the equivalent iron weight content is 10%, and the pH value is 2; the NDA900 type resin after washing, drying and pretreatment is added in batches at a feeding rate of no more than 1 / 10 of the resin addition amount within 15 minutes. 3 In the reaction kettle of the solution, NDA900 type resin and FeCl 3 The solid-to-liquid weight ratio of the solution is 2:1, and at 35°C, keep stirring for 2 hours to prepare FeCl-loaded 4 - Strongly basic anion resin intermediate; All the other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com