Wet powder drying system based on closed-loop conveying

A drying system and wet powder technology, applied in drying solid materials, drying cargo handling, drying gas layout, etc., can solve problems such as bulkiness, leakage of organic waste, and complex recovery devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

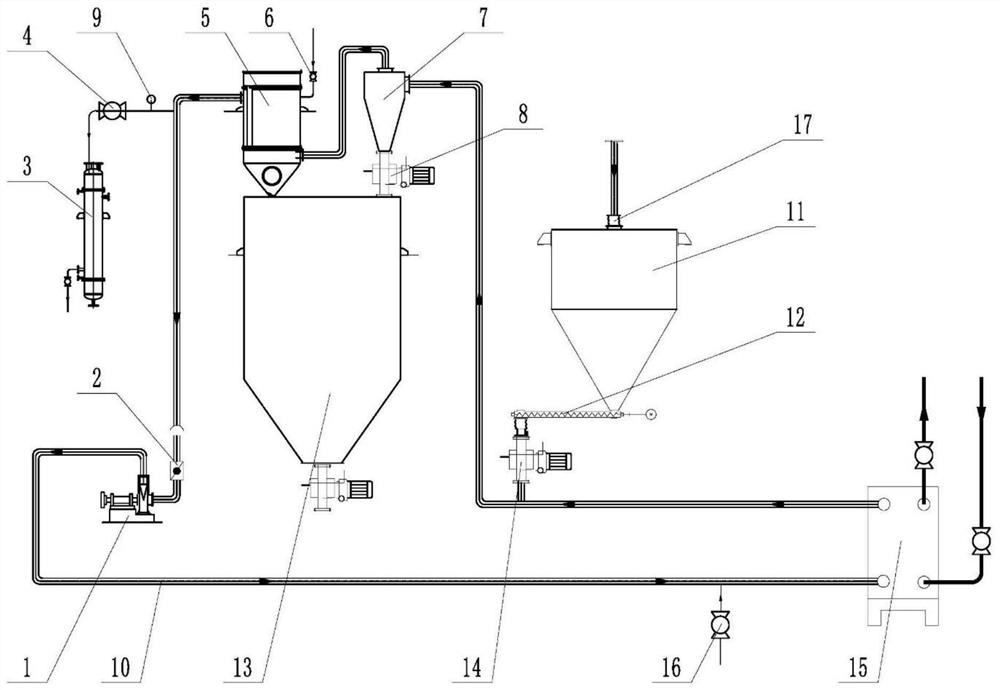

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The present invention is a wet powder drying system based on closed-loop conveying, such as figure 1 As shown, it includes a wet powder discharge bin 11 capable of holding wet powder, the bottom of the wet powder discharge bin 11 is connected to a screw conveyor 12, the outlet of the screw conveyor 12 is connected to a star-shaped discharge valve 14, and the outlet of the discharge valve passes through a feeding pipeline Connected to the inlet end of the cyclone separator 7, the feeding pipeline can not only transport the wet powder in the wet powder lower hopper 11 to the cyclone separator 7, but also connect the hot air unit to the feeding pipeline, which can provide hot air for the feeding pipeline, The wet powder is dried under the action of the hot air flow, the material outlet end of the cyclone separator 7 is connected to the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com