Feeding equipment of reaction container of reaction kettle

The technology of reaction vessel and feeding equipment is applied in the field of feeding equipment of reaction vessel and reaction vessel, which can solve the problems of affecting product quality, uneven reaction, excessive reaction, etc., and achieve the effect of avoiding high rotation frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

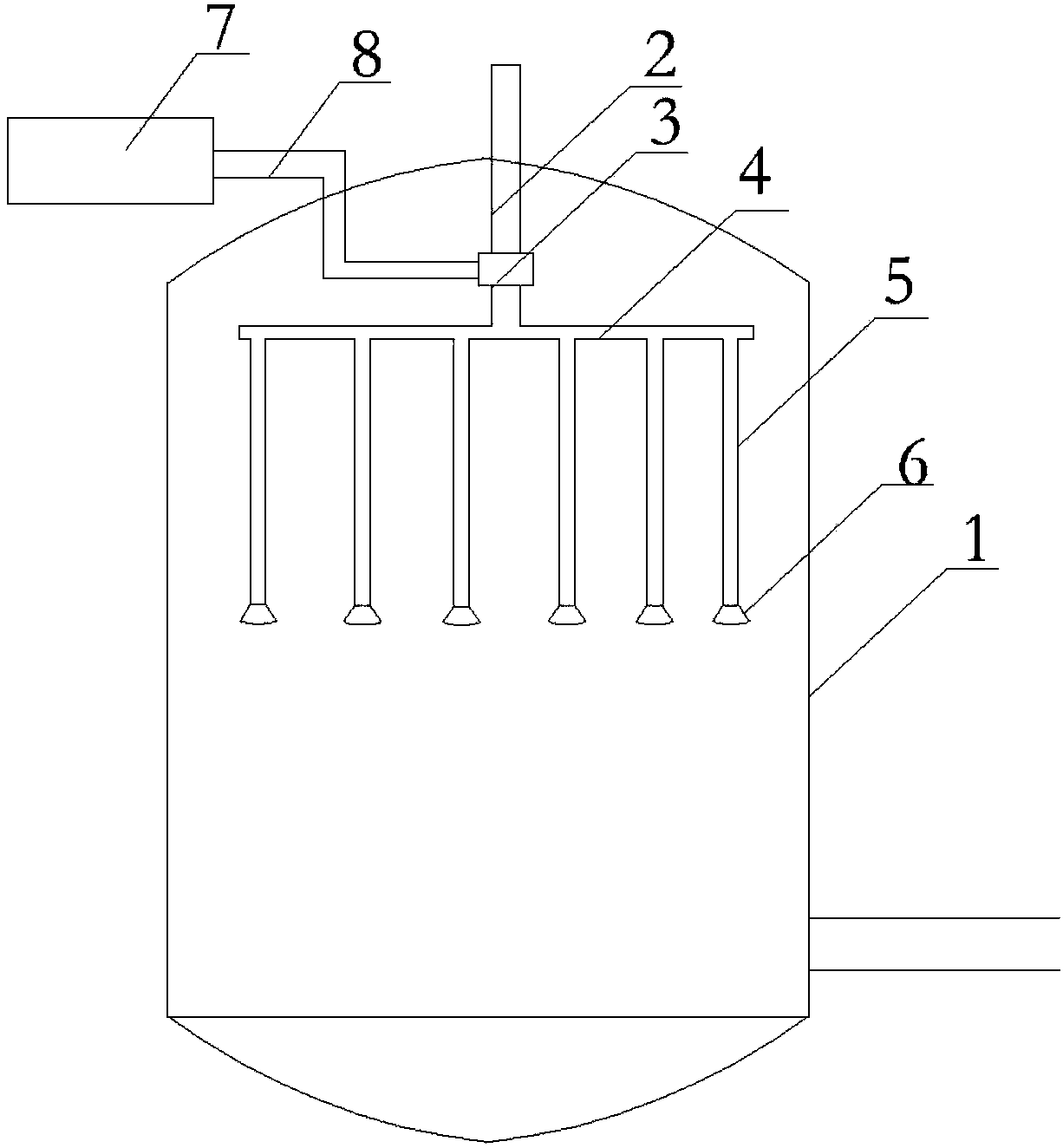

[0022] Such as figure 1 As shown, a reactor vessel feeding equipment includes a drive motor 7, a universal joint 3, an inlet pipe 2, a branch main pipe 4, a branch branch pipe 5, a reactor main body 1, and an inlet pipe 2 extends into the reactor main body 1. Inside, the inlet pipe 2 is connected with the branch main pipe 4. The branch main pipe 4 is provided with two or more branch pipes 5, and the branch branch pipe 5 communicates with the inside of the branch main pipe 4; the universal joint 3 is connected with the main shaft of the driving motor 7, and the universal joint The rotation of the joint 3 drives the rotation of the branch pipe 4.

[0023] Wherein, the drive motor 7 is connected to a frequency converter.

[0024] Wherein, the inlet pipe 2 is connected to the branch main pipe 4 through a universal joint 3.

[0025] Wherein, the lower end of the branch pipe 5 is provided with a spray head 6.

[0026] Wherein, the spray head 6 is provided with a plurality of spray holes o...

Embodiment 2

[0034] Such as figure 1 As shown, a reactor vessel feeding equipment includes a drive motor 7, a universal joint 3, an inlet pipe 2, a branch main pipe 4, a branch branch pipe 5, a reactor main body 1, and an inlet pipe 2 extends into the reactor main body 1. Inside, the inlet pipe 2 is connected with the branch main pipe 4. The branch main pipe 4 is provided with two or more branch pipes 5, and the branch branch pipe 5 communicates with the inside of the branch main pipe 4; the universal joint 3 is connected with the main shaft of the driving motor 7, and the universal joint The rotation of the joint 3 drives the rotation of the branch pipe 5.

[0035] Wherein, the inlet pipe 2 is fixed on the universal joint 3.

[0036] Wherein, the lower end of the branch pipe 5 is provided with a spray head 6.

[0037] Wherein, the spray head 6 is provided with a plurality of spray holes on the upper and lower sides.

[0038] Wherein, the main shaft of the driving motor 7 is connected to the uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com