Coal transportation humidification system

A humidification system and coal technology, used in transportation and packaging, railway car body parts, fire rescue and other directions, can solve the problems of accelerated aging of carriages and carriage connection structures, decreased coal preservation effect, and increased coal surface humidity, etc. Convenience, preventing coal dust from scattering, and facilitating mutual adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

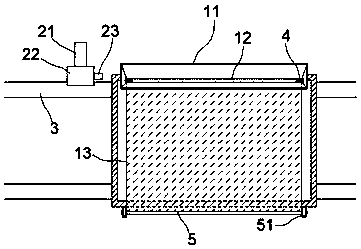

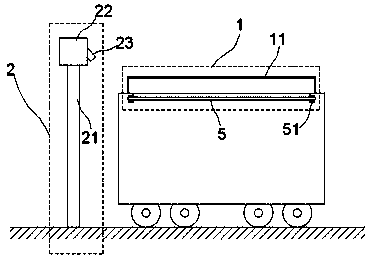

[0016] exist figure 1 , figure 2 In the shown embodiment, the coal humidification system includes a moisturizing device 1 and a water replenishing device 2, such as figure 2 Shown in the dotted line box in the middle; the moisturizing device 1 is installed on the top of a side wall of the compartment, and the water replenishing device 2 is equidistantly arranged on one side of the track 3;

[0017] The moisturizing device 1 includes a storage tank 11, and a strip-shaped outlet is provided at the bottom of the storage tank 11; a support shaft 12 parallel to the outlet is installed in the storage tank 11, and the support shaft 12 is connected to the outlet. The side walls of the storage tank 11 are connected by a return coil spring 4, and a lock is provided at the return coil spring 4; the support shaft 12 can rotate freely around its own axis relative to the side wall of the storage tank 11; A humidifying net 13 is coiled on the supporting shaft 12, one side of the humidify...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com