Ore conveyer

A technology for conveyors and ores, which is applied in the directions of conveyors, transportation and packaging, loading/unloading, etc., and can solve problems such as ore rolling and ore falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described below.

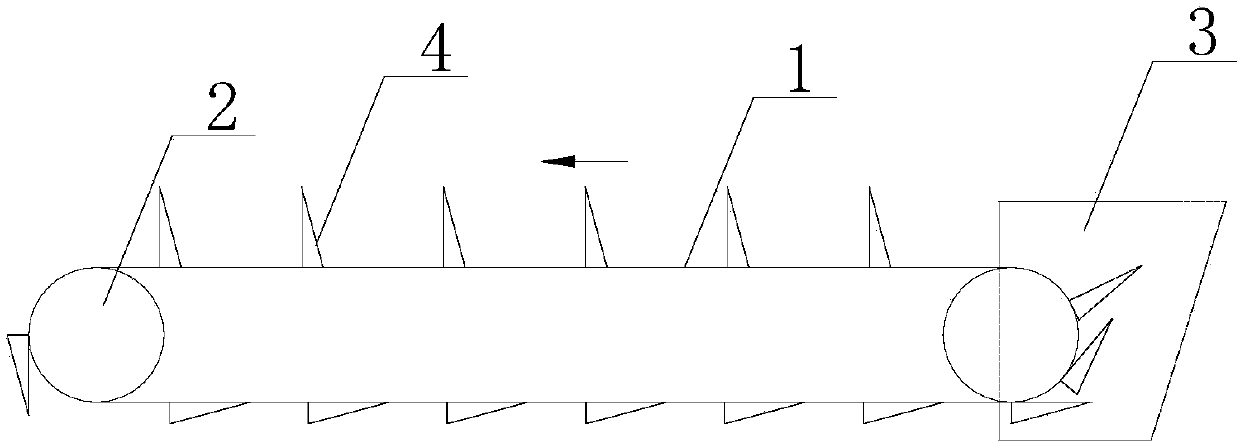

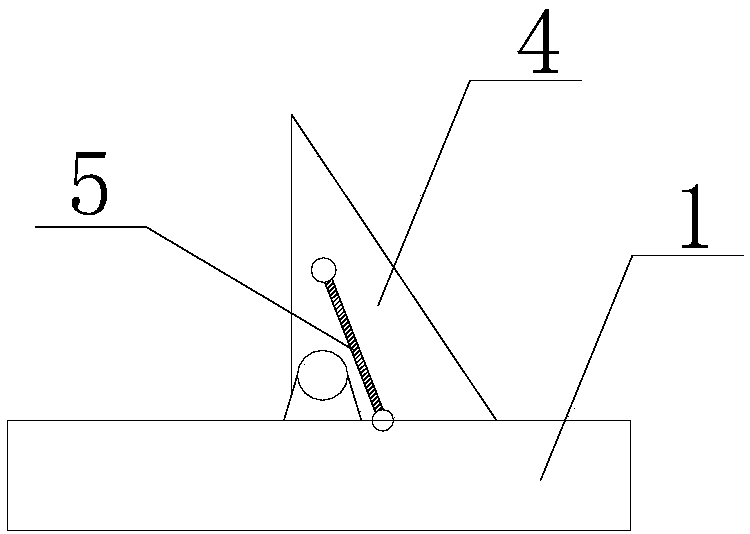

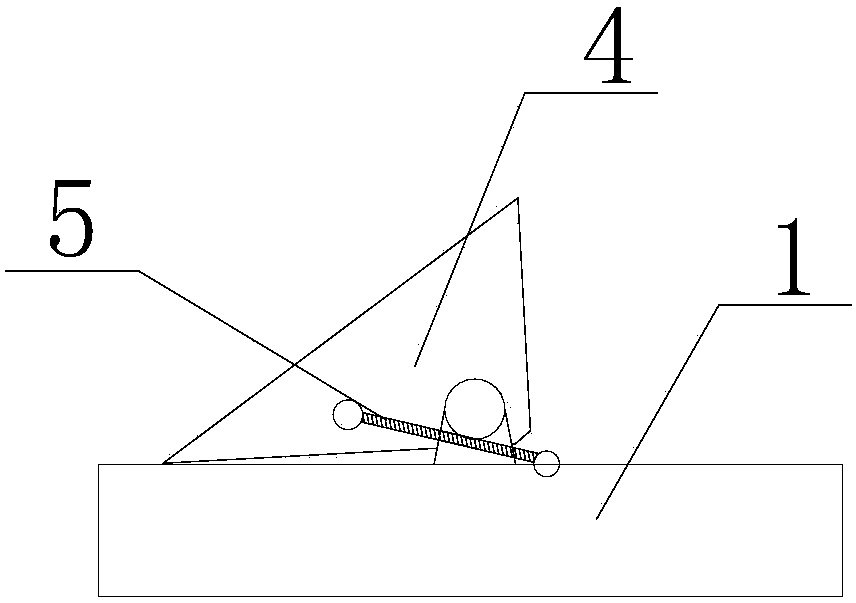

[0014] The ore conveyor disclosed in the present invention comprises a conveyor belt 1, a roller 2 and a feed hopper 3, the roller 2 is arranged at both ends of the conveyor belt 1, the feed hopper 3 is arranged at the feeding end of the conveyor belt 1, and the The conveyer belt 1 is arranged with a plurality of transverse propulsion plates 4 arranged along the conveying direction, and the vertical section of the transverse propulsion plate 4 along the axial direction of the conveyer belt 1 is a right-angled triangle structure, and the right angle position of the transverse propulsion plate 4 is in the same position as the conveyer belt. 1 is hinged, and a tension spring 5 is connected between the horizontal push plate 4 and the conveyor belt 1;

[0015] When one right-angled edge of the transverse pusher plate 4 is attached to the conveyor belt 1, the tension spring 5 is located outside the hinge point of the transve...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap