Spiral falling device of full-automatic bamboo pipe production line

A production line, fully automatic technology, applied in transportation and packaging, conveyors, conveyor objects, etc., can solve the problem of lack of automatic transportation and automatic arrangement, and achieve the effect of reducing labor costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

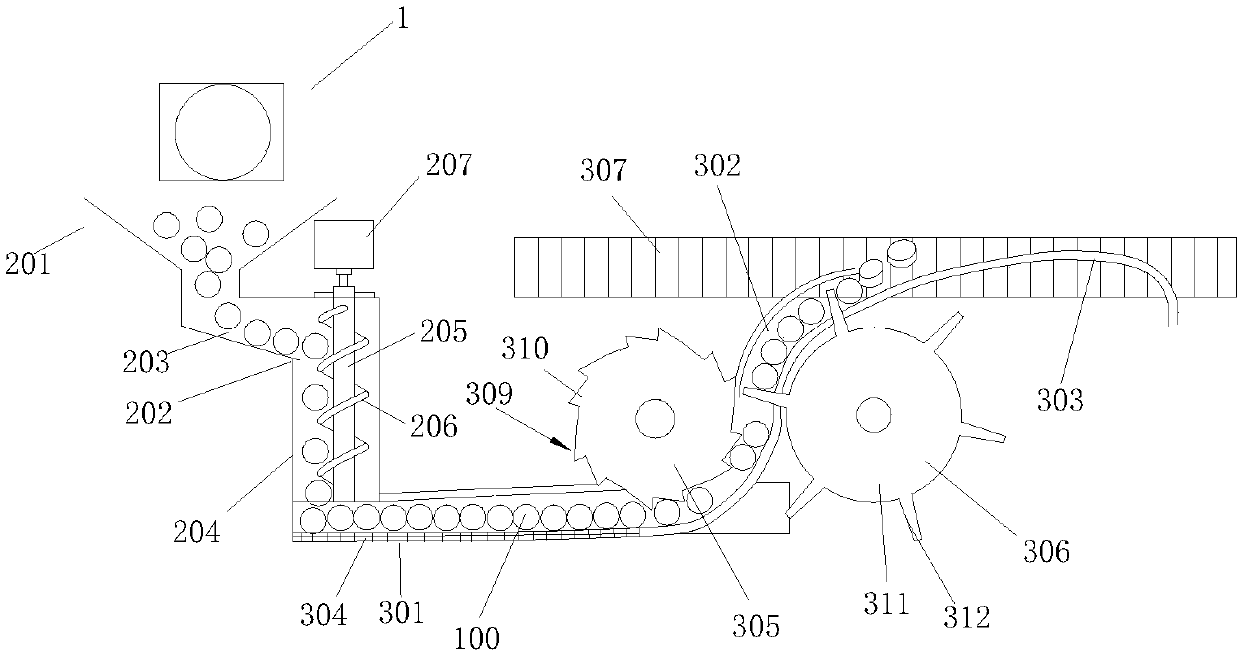

[0010] Embodiment: a kind of spiral falling device of bamboo tube full-automatic manufacturing production line, constitutes as figure 1 Shown, comprise the blanking mouth 201 that is arranged on the bamboo tube processing device 1 below, the blanking bin 202 is provided with the blanking bin 202 below, and the blanking bin 202 includes the blanking inclined cavity 203 that links to each other with the blanking port 201, and the blanking inclined The bottom of cavity 203 is provided with blanking vertical chamber 204, and vertical shaft 205 is arranged in blanking vertical chamber 204, and the surface of vertical shaft 205 is provided with blanking thread 206, and the surface of blanking bin 202 is provided with blanking motor 207, and the blanking motor The output end of 207 links to each other with vertical shaft 205;

[0011] The specific working principle: the bamboo tube falls from the blanking opening into the blanking inclined cavity, and automatically rolls down on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com