Combined type symmetrical elevator balance block assembly

A balance weight and symmetrical technology, which is applied in the direction of transportation and packaging, lifting equipment in mines, etc., can solve problems such as easy shaking or bumping, shaking or bumping, and the influence of the stability of the counterweight and balance weight, so as to ensure stability stability, ease of transportation, and the effect of providing packing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

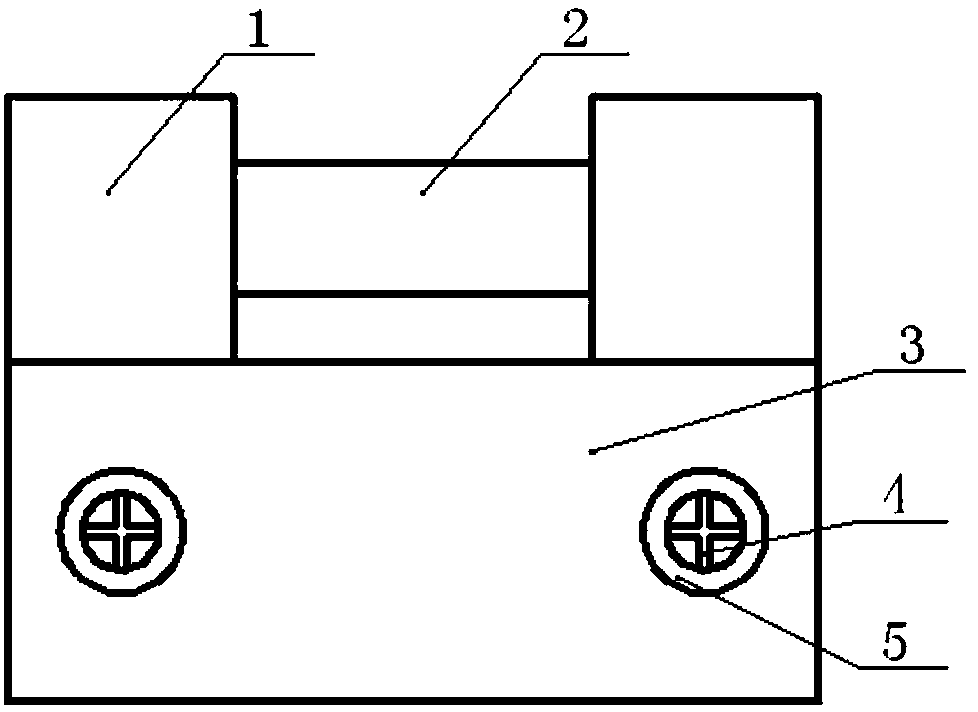

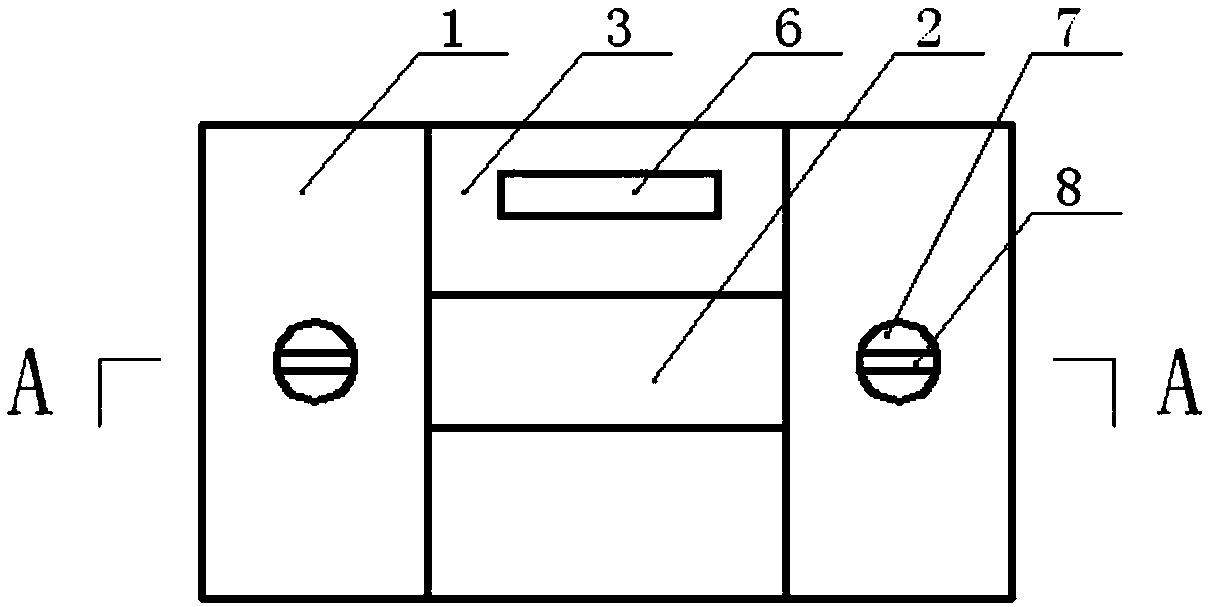

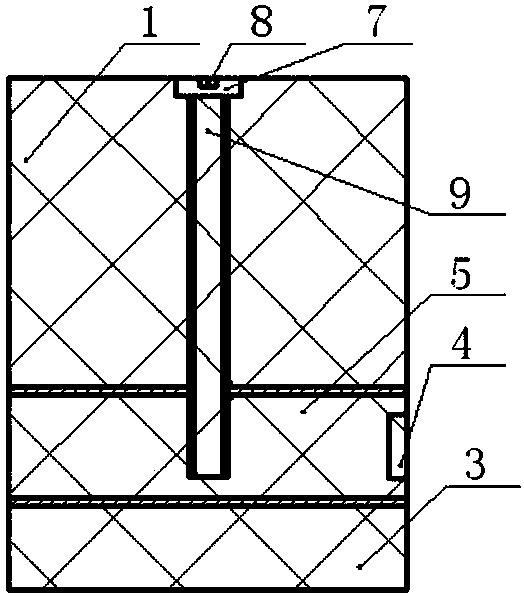

[0024] A combined symmetrical elevator balance block assembly, the base body 3 of the balance block is symmetrically formed with shoulders 1 on the upper end surface, and a handle 2 is fixed between the two shoulders.

[0025] Innovation point of the present invention is:

[0026] A through hole is horizontally arranged in the base of each balance weight, and threads are arranged in the through hole. The balance weight also includes a fixed shaft 5 and a plurality of positioning pins 9. The through holes of the balance weights arranged in parallel are provided with a downward positioning hole in the middle of the shoulder on each balance weight. The positioning pins are coaxially engaged and install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com