A method for controlling the top temperature of a blast furnace

A temperature control method and blast furnace technology, applied to blast furnaces, blast furnace details, furnaces, etc., can solve problems affecting blast furnace stability, forward movement, increased water consumption, unfavorable blast furnace forward movement, etc., to reduce the amount of water drawn from the top of the furnace, increase The effect of generating electricity and reducing the frequency of fetching water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

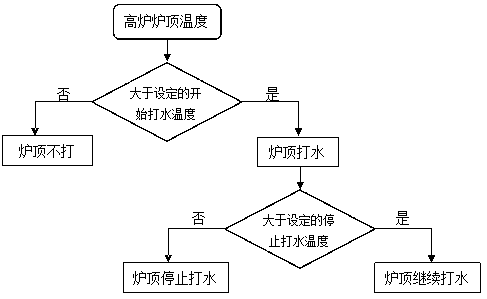

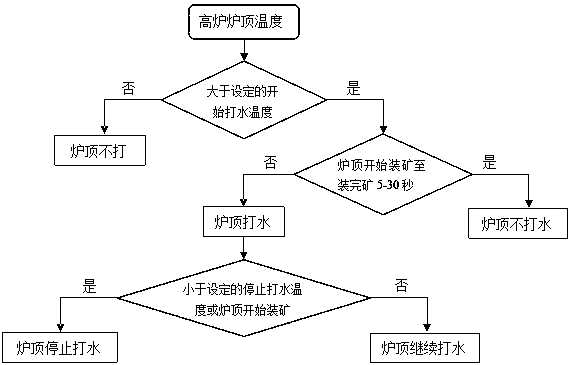

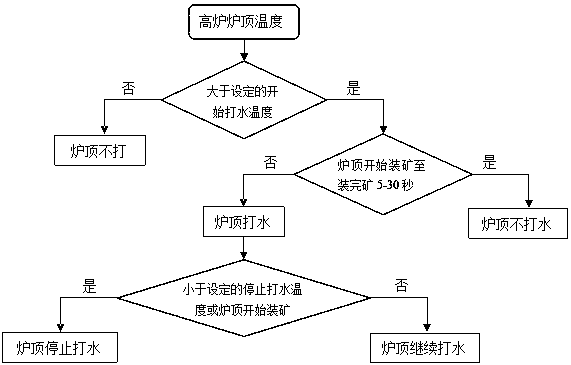

Image

Examples

Embodiment 1

[0020] The water fetching from the top of the 6# blast furnace in Taiyuan Iron Works is controlled by the first-level system of the blast furnace. After the first-level system sets the interlocking conditions, the program will automatically run according to the interlocking conditions, which can realize automatic water fetching. The trial process includes the following steps:

[0021] Step 1: Set the linkage between the furnace top water pumping and charging: when the top temperature is higher than the set starting water pumping temperature of 210°C, the furnace The top does not start water fetching; only when the top temperature is greater than the set start water fetching temperature, and the furnace top is loaded with ore 10 seconds before the next time before the next time the ore is loaded, the furnace top water fetching is started;

[0022] Step 2: The conditions for stopping the top water pumping are: when the top temperature is lower than the set stop water pumping temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com