Hydraulic pump

A technology of hydraulic pump and liquid inlet, applied in the field of hydraulic pump, can solve the problems of inconvenient hydraulic pump installation, increase in size of hydraulic pump, high manufacturing cost, etc., and achieve the effect of improving efficiency, saving energy consumption and ensuring balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

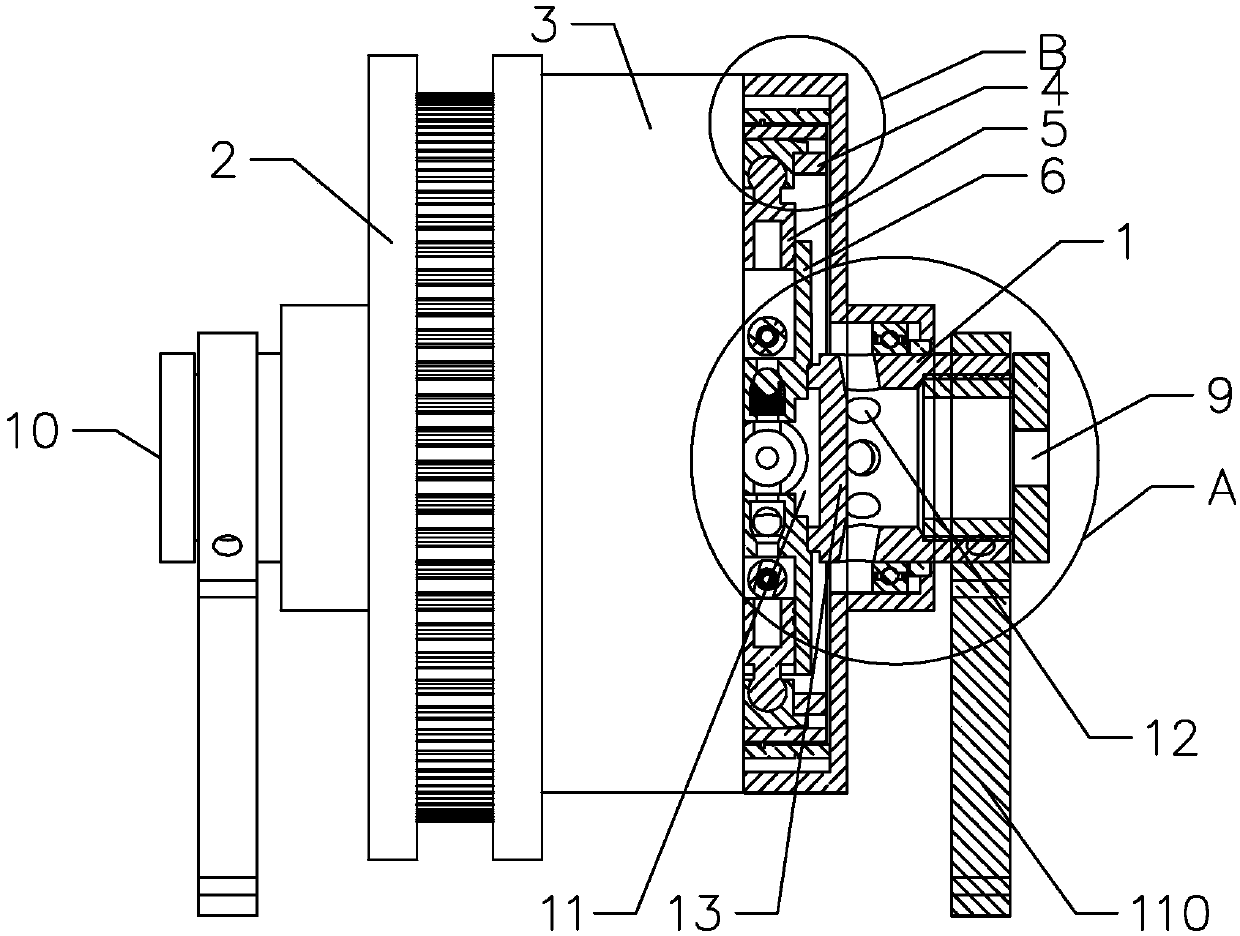

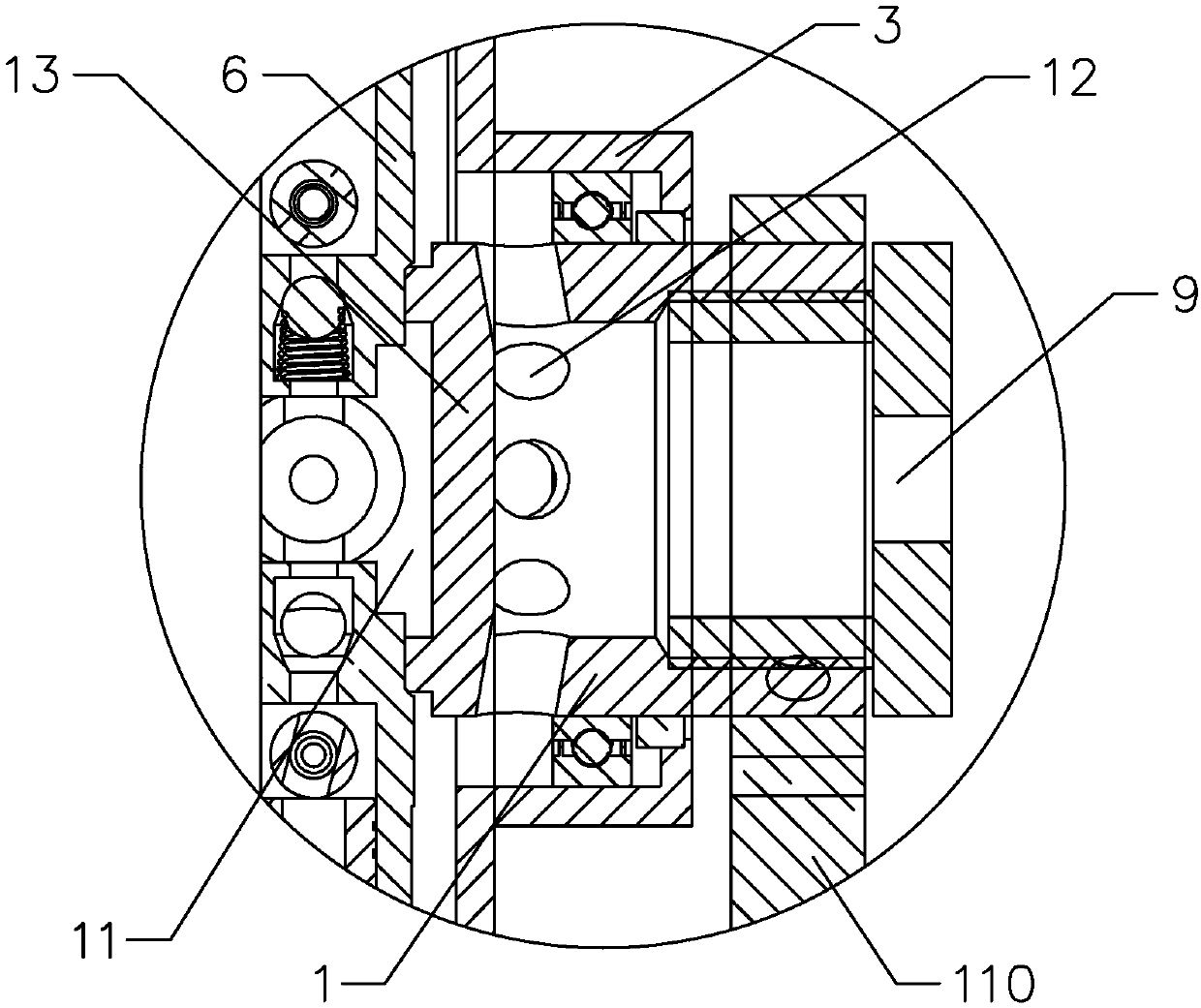

[0035] Such as Figure 1 to 4 As shown, the present invention provides a hydraulic pump including a central shaft with a hollow cavity 11, a transmission wheel 2 rotatably connected to the central shaft 1, and an eccentric sleeve 3 connected to the transmission wheel 2, and the central shaft 1 is sleeved There are ball bearings, and the transmission wheel 2 is sleeved on the ball bearings to realize the rotational connection to the central shaft 1. The central shaft 1 is a metal central shaft, specifically a stainless steel shaft, which improves the durability of the central shaft. Improve the overall durability of the hydraulic pump; the transmission wheel 2 is connected to an external power source for transmission. The eccentric sleeve 3 is provided with a steel ring 4 and a push rod assembly. The push rod assembly includes a push rod 5 arranged on the steel ring 4 and located in the center A push rod sleeve 6 on the shaft 1 and matched with the push rod 5. The push rod 5 is ...

Embodiment 2

[0044] The difference between this embodiment and the first embodiment is that the eccentric sleeve includes a first eccentric sleeve and a second eccentric sleeve.

[0045] In this embodiment, such as Figure 5 As shown, the eccentric sleeve includes a first eccentric sleeve 31 and a second eccentric sleeve 32, and the transmission wheel 2 is arranged between the first eccentric sleeve 31 and the second eccentric sleeve 32. In this way, by providing two eccentric sleeves, the external power source can be The turning torque becomes greater, which is converted into greater hydraulic pressure.

[0046] Specifically, the first eccentric sleeve 31 and the second eccentric sleeve 32 are arranged symmetrically with respect to the transmission wheel 2, so that the balance of the two eccentric sleeves during rotation can be well ensured, and the flow rate of the liquid flow can be well ensured. That is, the stability and reliability of the hydraulic pump during operation are well guarantee...

Embodiment 3

[0048] The difference between this embodiment and the first embodiment is that multiple sets of push rod assemblies distributed in a "cross" shape are arranged side by side in parallel along the axial direction of the central axis.

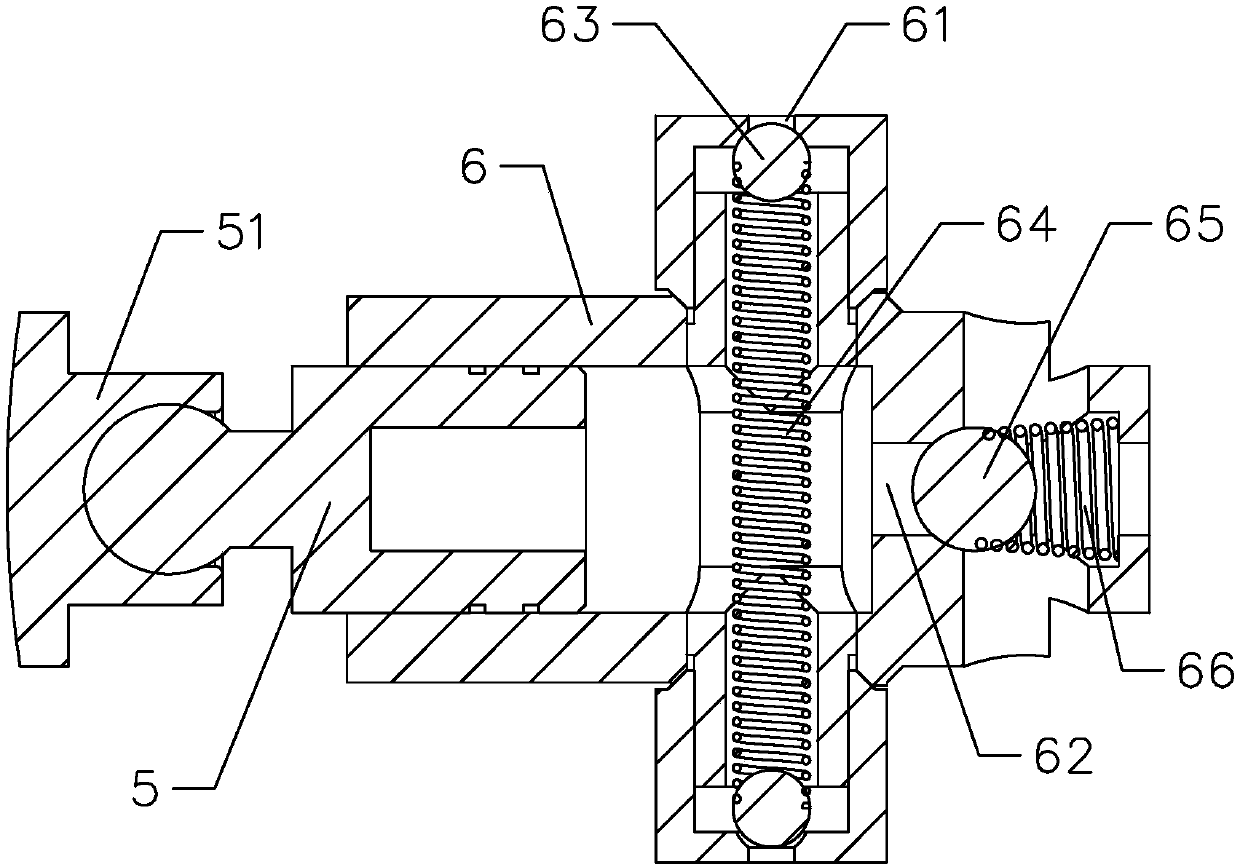

[0049] In this embodiment, such as Image 6 As shown, there are multiple sets of push rod assemblies distributed in a "cross" shape and are arranged side by side in parallel along the axial direction of the central axis 1, that is, multiple push rods 5 and push rod sleeves 6 are provided, and they cooperate with each other to form a liquid contact Specifically, there are three sets of push rod assemblies distributed in a cross shape. Each push rod assembly contains four push rods 5 and four corresponding push rod sleeves 6, so that when the eccentric sleeve 3 rotates , The twelve push rods 5 respectively reciprocate in the corresponding twelve push rod sleeves 6 to pressurize the liquid flow, and the pressurized liquid flows through the liquid outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com