Integrated multi-group pneumatic high-frequency electromagnetic valve and working method thereof

A high-frequency solenoid valve, integrated technology, applied in the direction of valve operation/release device, valve details, valve device, etc., can solve the problems of unreasonable structural design of solenoid valve, poor response flexibility, inaccurate control, etc., and achieve saving Effects of power consumption, short turn-on time, and simplified overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

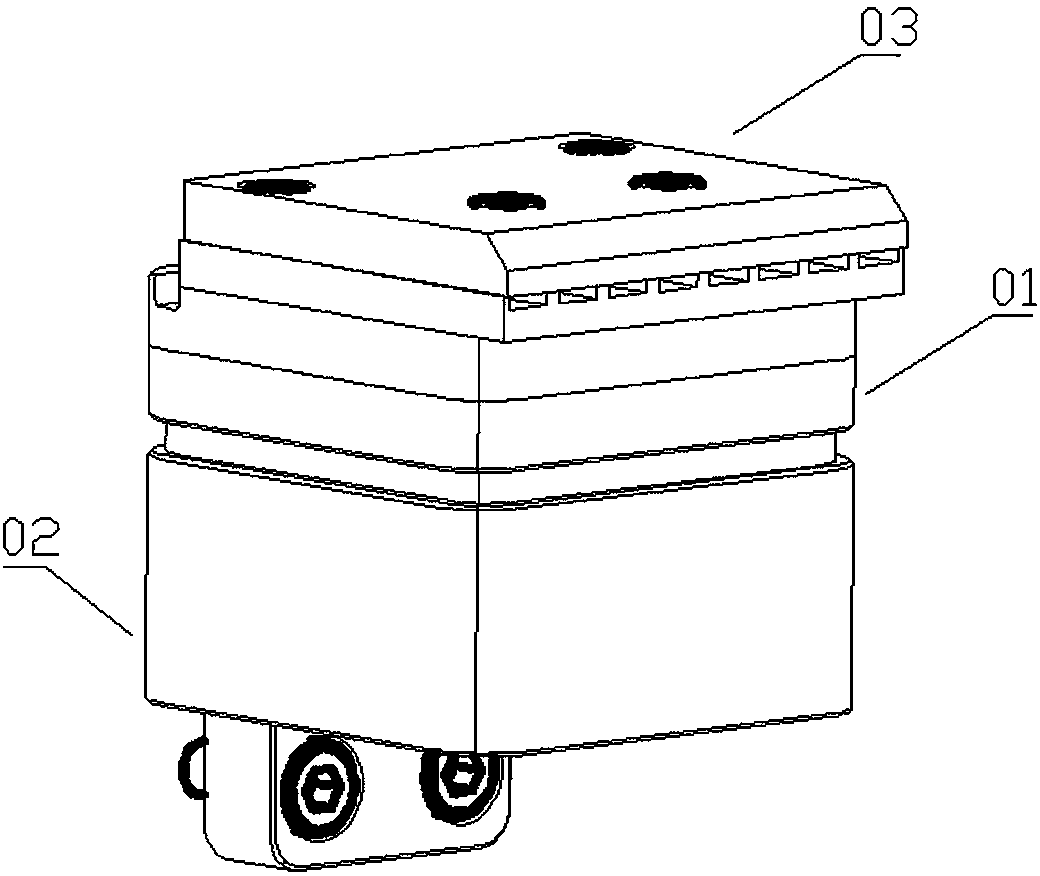

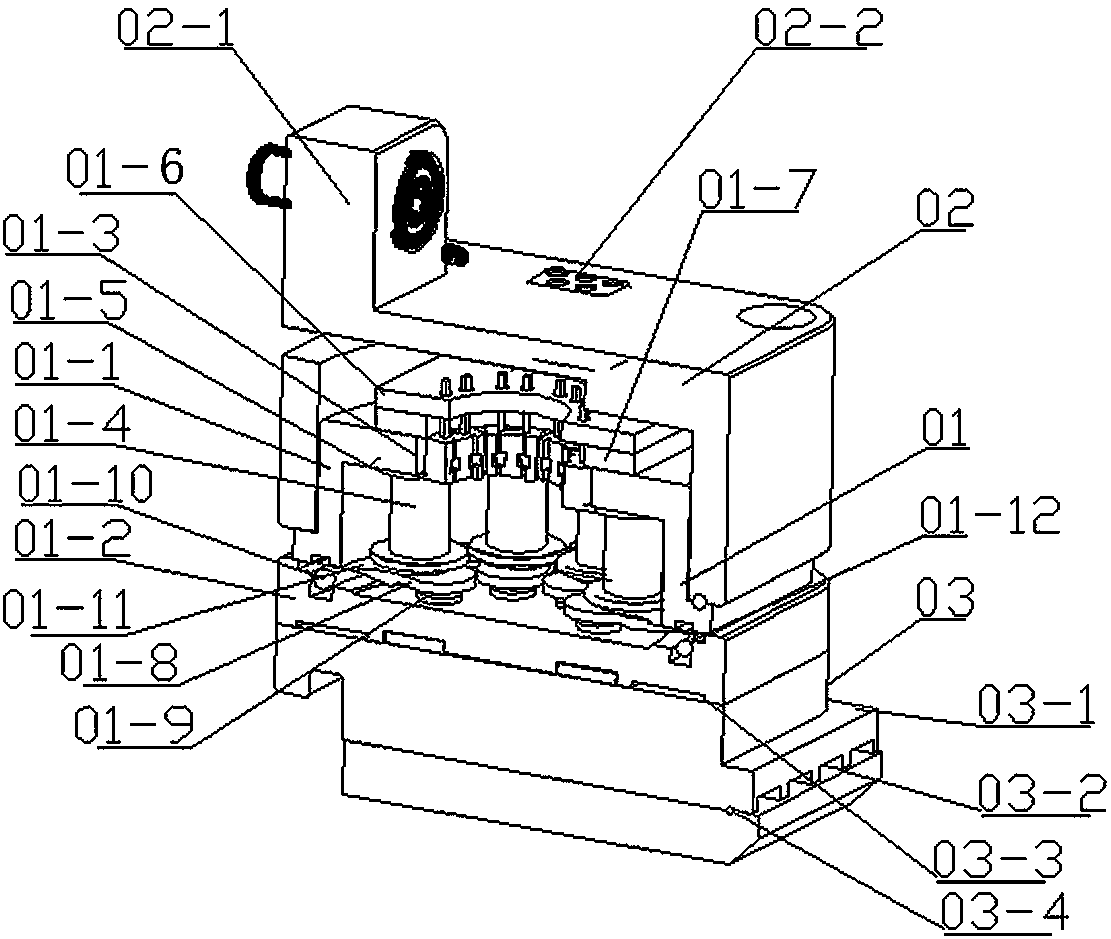

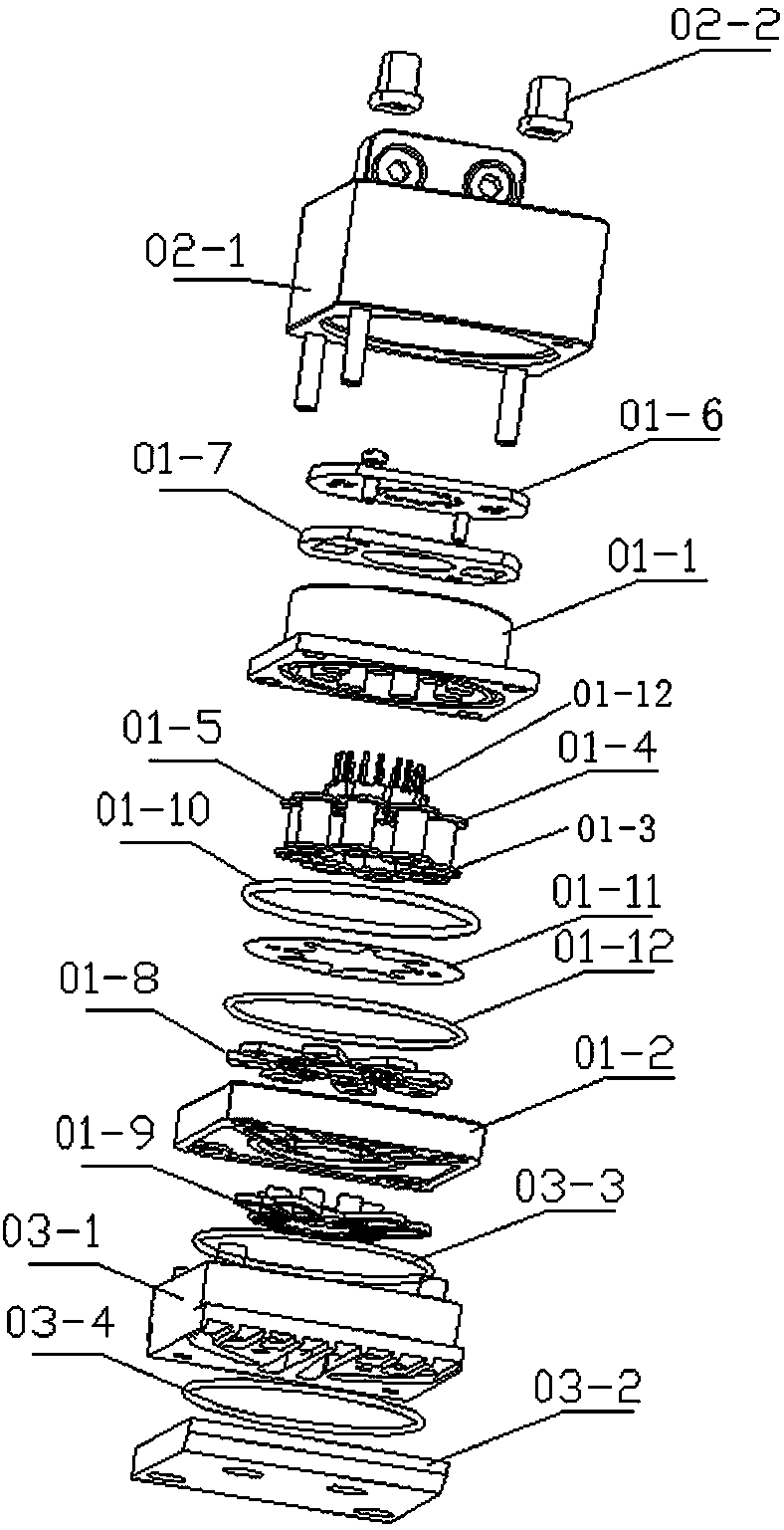

[0028] Such as Figure 1-6 As shown, the integrated multi-group pneumatic high-frequency solenoid valve of the present invention includes a valve body, and the valve body includes: a main valve body 01, an integrated air intake connecting plate assembly 02 installed above the main valve body The integrated gas outlet assembly 03 under the valve body 01;

[0029] The main valve body 01 includes a main valve body functional plate 01-1 and a main valve body airway adapter plate 01-2 located below the main valve body functional plate 01-1, and the main valve body functional plate 01- 1 is provided with respective ring-shaped valve magnetic cores 01-3, the outer side of the valve magnetic cores 01-3 is covered with a magnetic coil 01-4, and the magnetic coil 01-4 is wound with an excitation copper coil 01- 5. The magnetic coil 01-4 is connected to the valve circuit board 01-6 through the terminal 01-12, and the valve circuit board 01-6 is provided with an insulating plastic plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com