Image splicing and bending and deformation deflectionc method of long-shaft type parts based on laser ray marking

A technology of bending deformation and laser marking, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of image stitching without obvious feature points and limited measurement size, etc., and achieves easy practicality, high measurement accuracy, strong resistance The effect of interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with drawings and embodiments.

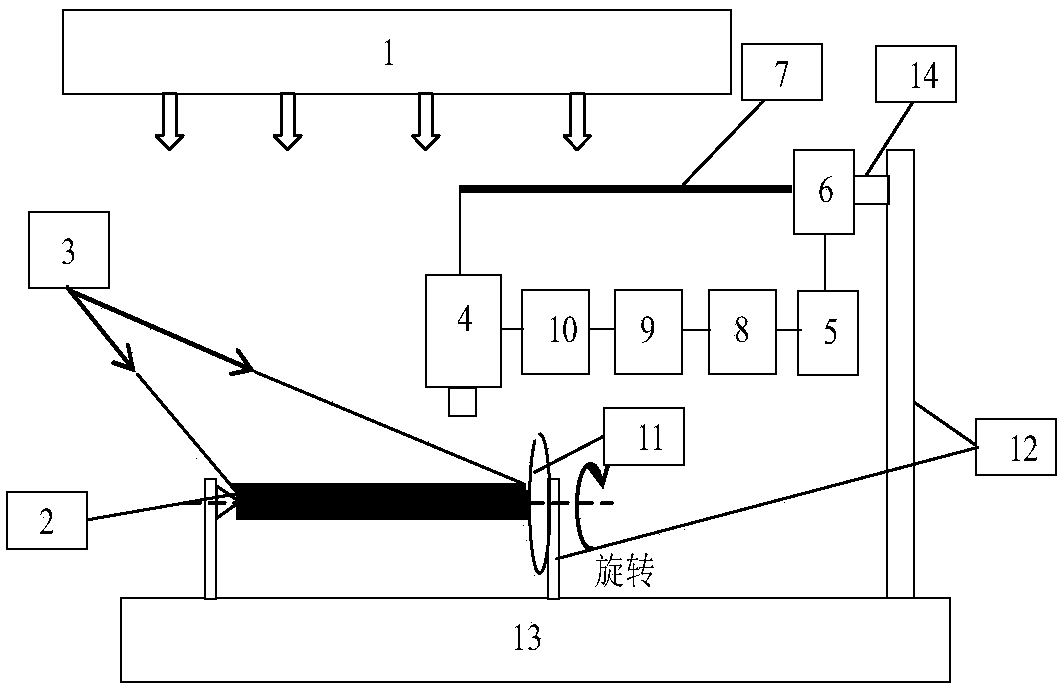

[0046] as attached figure 1 As shown, the system implemented by the present invention includes a light source system 1, a measured shaft part 2, a line laser 3, a CCD camera 4, a motor controller 5, a linear motor 6, a retractable mechanical arm 7, an image acquisition card 10, and a computer 8 , a digital image processing system 9, a chuck 11, a bracket 12, a precision vibration isolation platform 13 and a fixed mechanical arm 14.

[0047] The shaft part 2 to be tested is installed on the precision vibration isolation platform 13 through the bracket 12 horizontally with the axis, and one end of the shaft part 2 to be tested is connected to the chuck 11, and the shaft part 2 to be tested is driven to rotate by the chuck 11.

[0048] A bracket 12 is installed on the precision vibration isolation platform 13, and the linear motor 6 is installed on the top of the bracket 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com