Aircraft engine reverse push door switch movement durability test device

An aero-engine and durability test technology, which is applied in the direction of internal combustion engine testing, etc., can solve the problems of unclear display of the action position of the reverse push door, unreasonable detection of the action time of the reverse push door, and complicated control and display system, and achieves a practical and reliable structure. Simple structure and clear detection signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are given below in conjunction with the accompanying drawings, and the working principle of the aero-engine reverse push door switch movement endurance test device of the present invention will be further described through the embodiments.

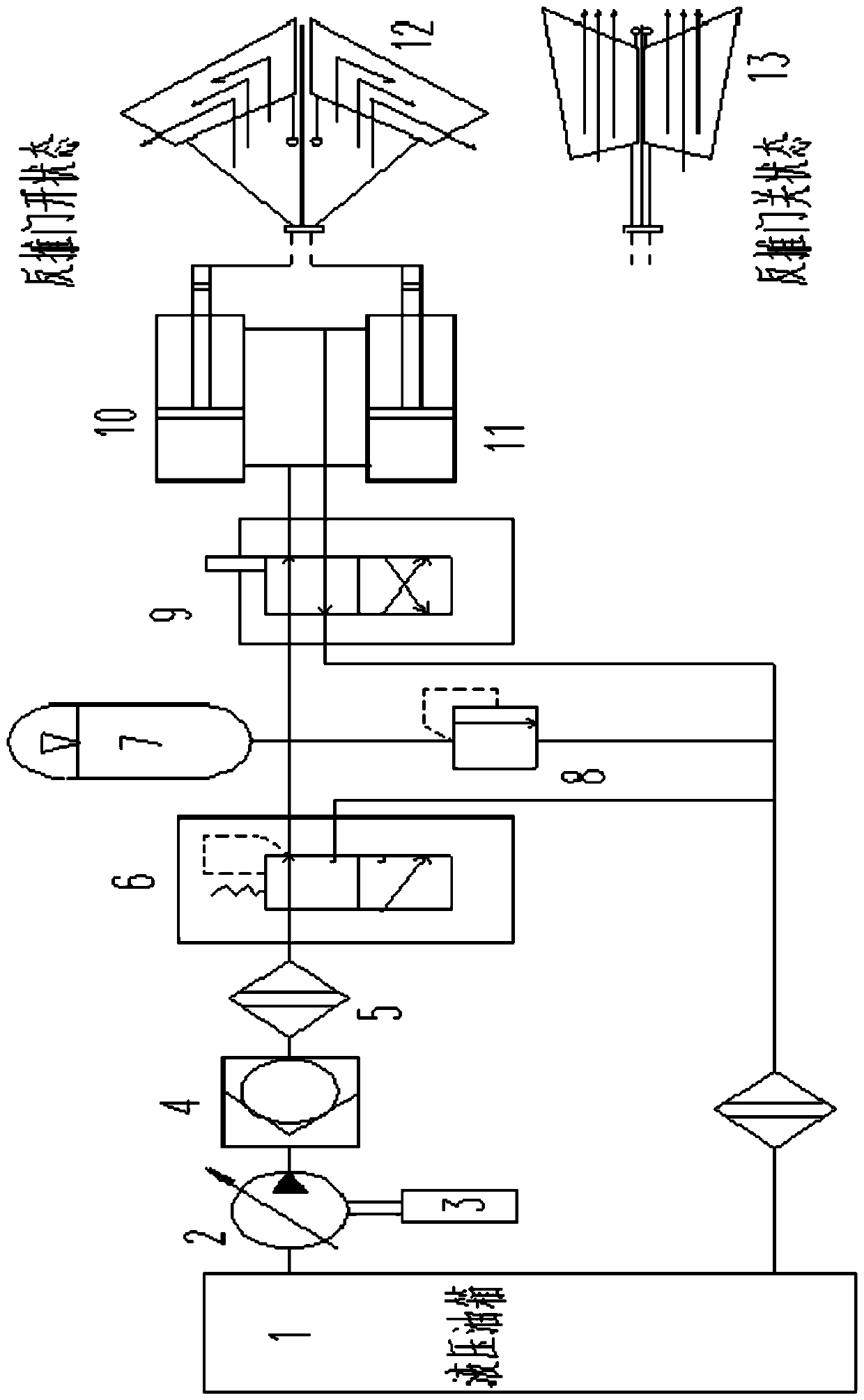

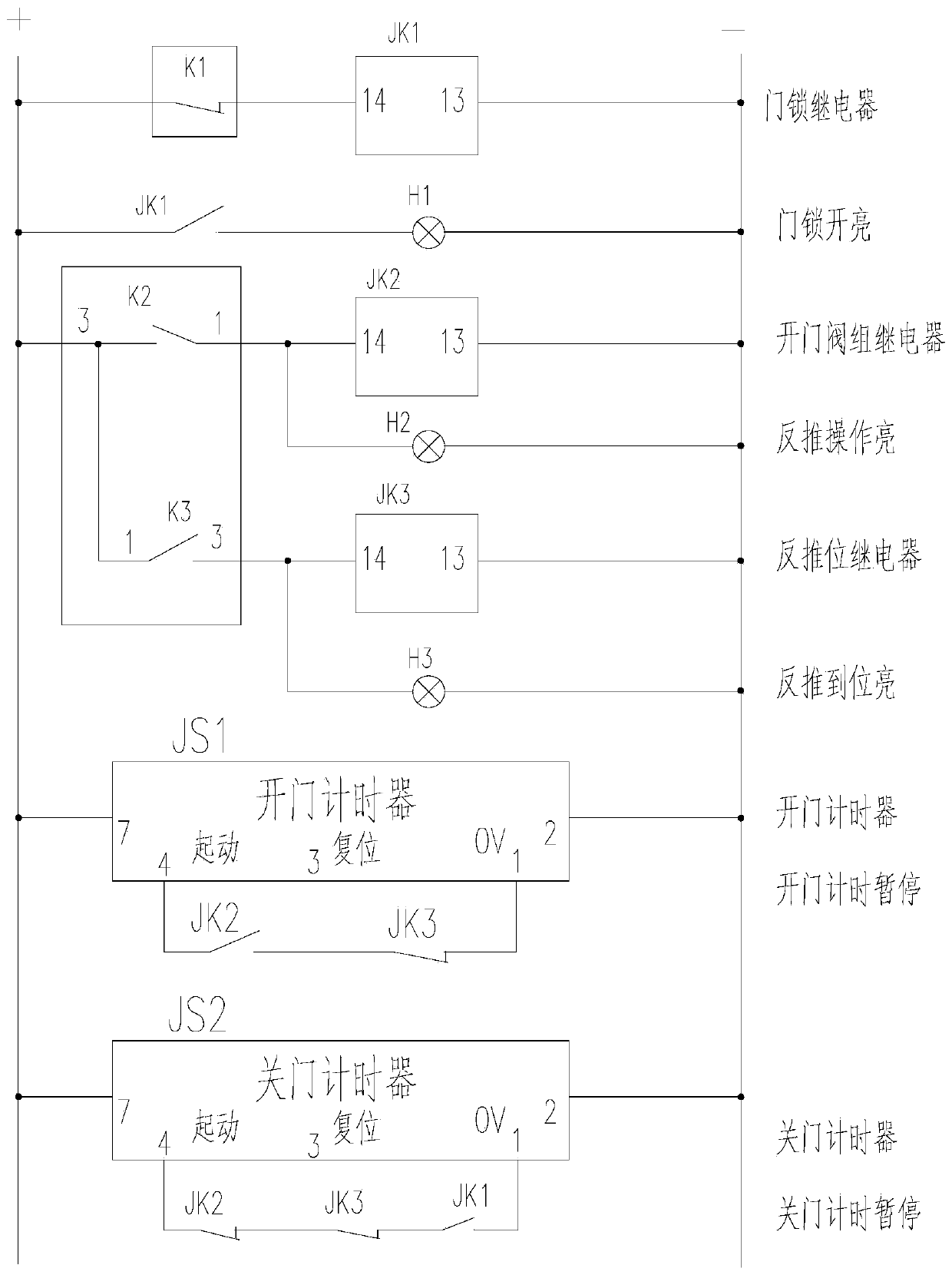

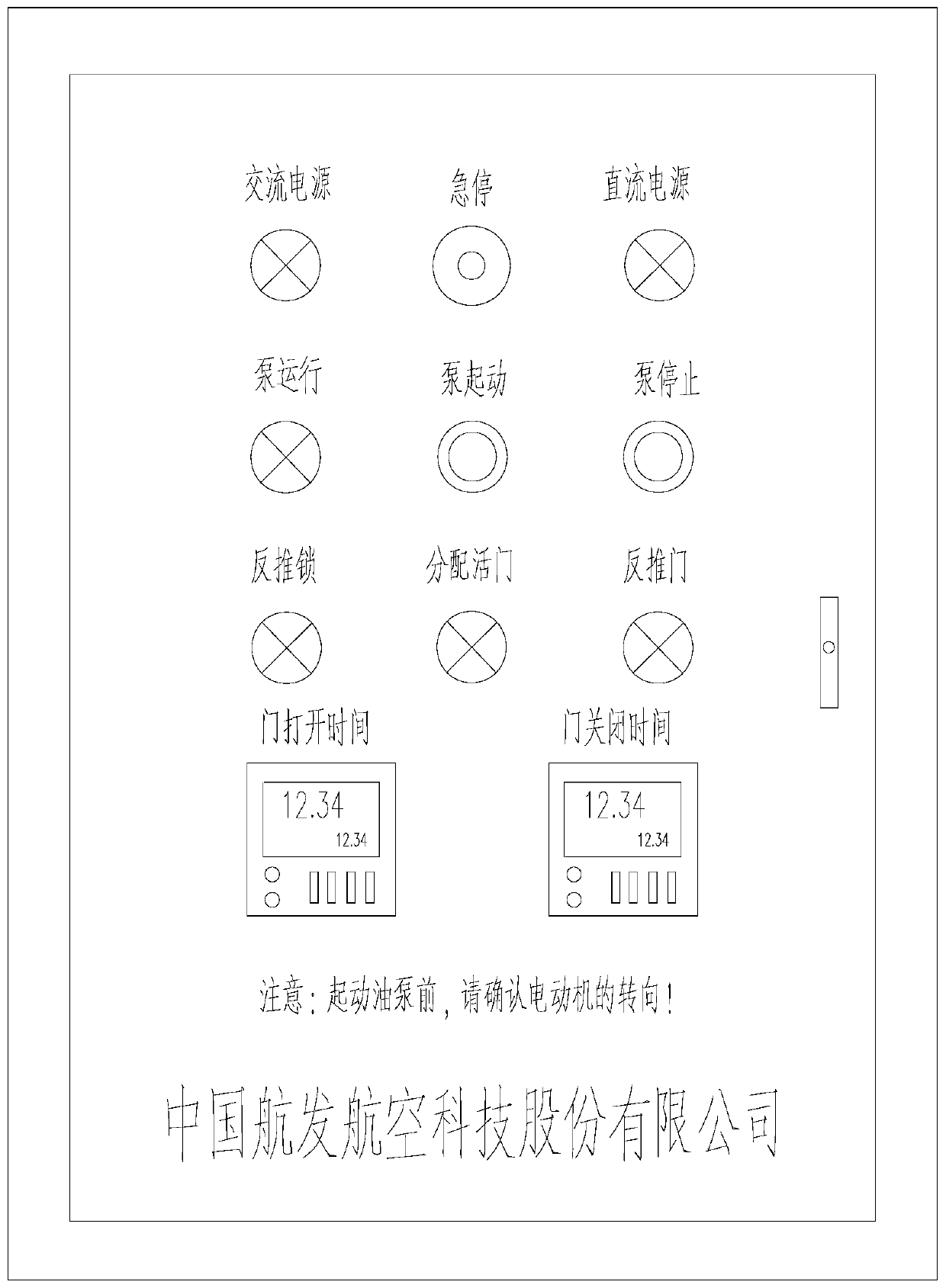

[0020] The aero-engine anti-push door switch motion endurance test device of this embodiment has a structure such as figure 1 , figure 2 and image 3 As shown, it is composed of a reverse push door switch motion control hydraulic system and a reverse push door switch motion control measurement and display system. The reverse push door switch movement control hydraulic system is a set of self-closed hydraulic system, such as figure 1 shown. The plunger type pressurized oil pump 2 whose inlet is connected to the hydraulic oil tank 1 is driven by the motor 3 to pressurize the hydraulic oil and output it, and then enters the one-way valve 4 . The function of the check valve is to prevent the rev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap