Bidirectional piston type pneumatic clamp for combined machining of automobile air conditioner compressor shell

A technology for compressor shells and automotive air conditioners, applied in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as high product rework rate or scrap rate, lower production efficiency, easy leakage, etc., and achieve improved repeatability The effect of positioning accuracy, reducing clamping time, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

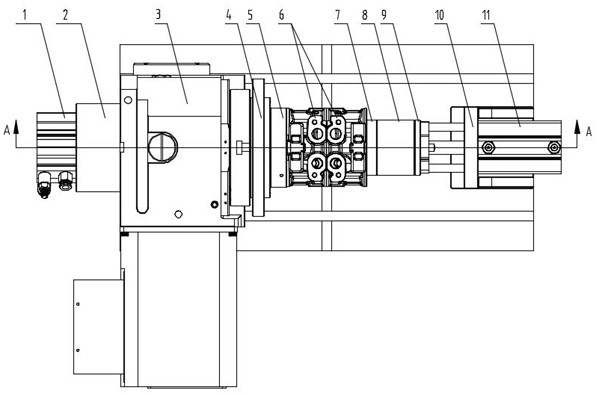

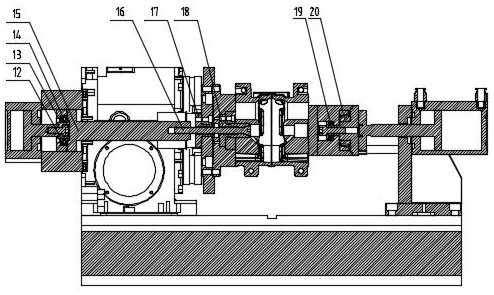

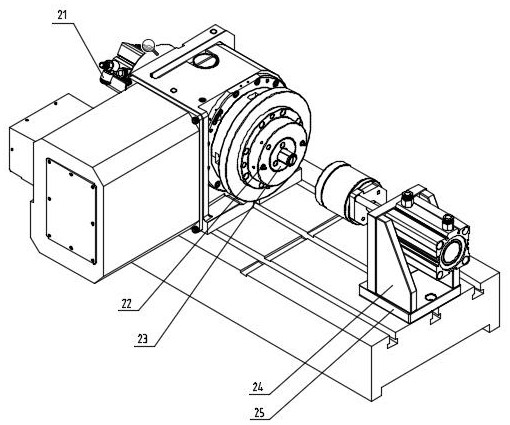

[0024] Example: such as Figure 1-Figure 3 As shown, a bidirectional piston type automobile air-conditioning compressor shell combination processing pneumatic clamp is composed of a clamp main body, a tensioning mechanism, a top tightening mechanism, and a rotating mechanism. The tightening mechanism is installed on the machine tool table, and the rotating mechanism is respectively connected with the tensioning mechanism and the top tightening mechanism.

[0025] The fixture main body is composed of numerical control indexing plate 3, transition plate 4, positioning plate 5, transition plate mandrel 17, expansion core 18, positioning pin 22, and dustproof cover 23. Expansion core 18, locating pin 22, dust cover 23 and locating plate 5 are fitted together in a clearance fit, then fixed on the transition plate 4 with bolts and the transition plate mandrel 17 is also fixed on the transition plate 4, and finally the transition plate 4 Installed on the numerical control indexing p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap