Battery module side plate and manufacturing process thereof

A battery module and side plate technology, applied in battery pack components, circuits, electrical components, etc., can solve the problems affecting the normal operation of the battery module and the insulation effect of the insulating layer, and achieve stable and reliable insulation performance and stable installation. High performance, the effect of ensuring insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

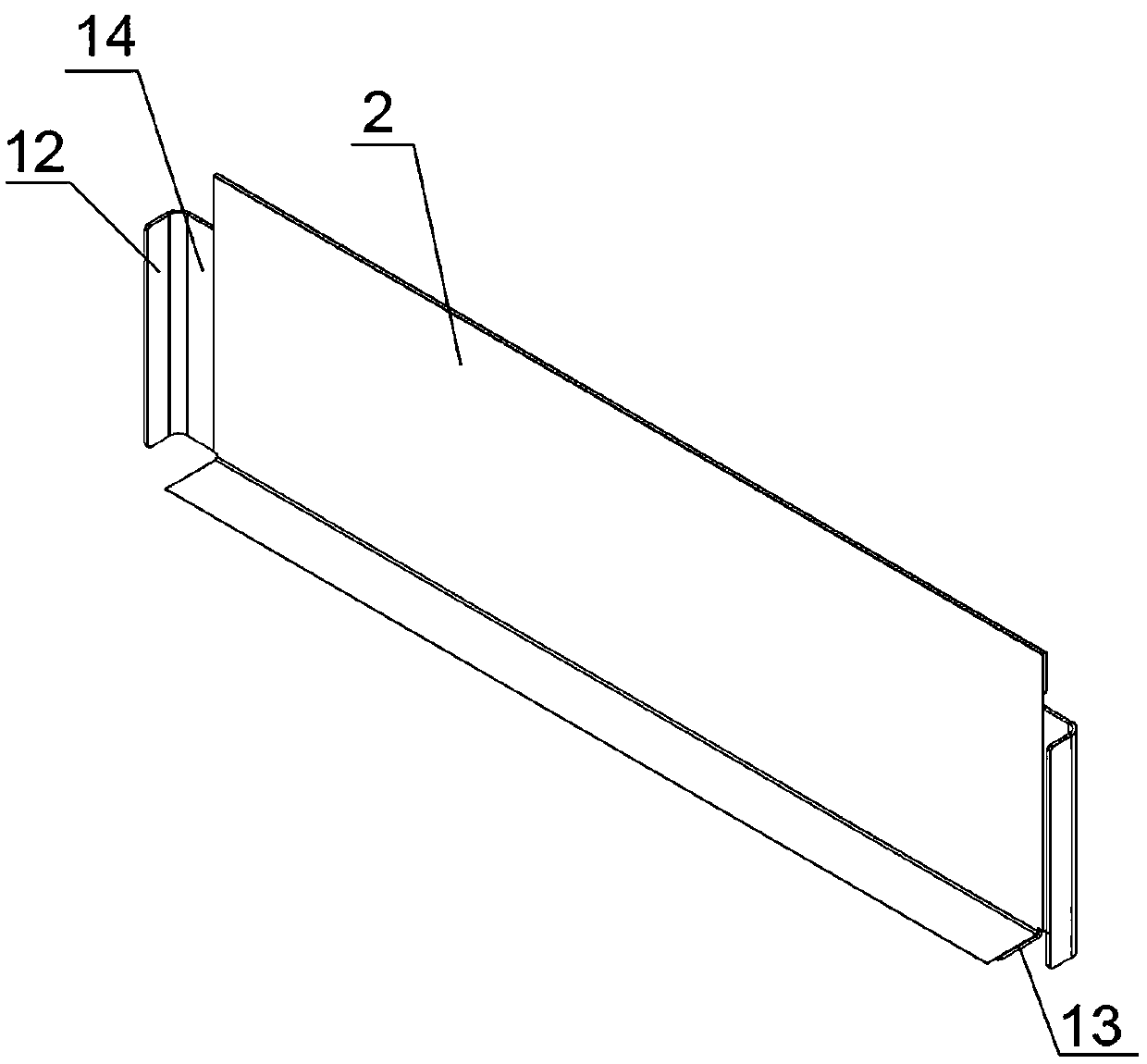

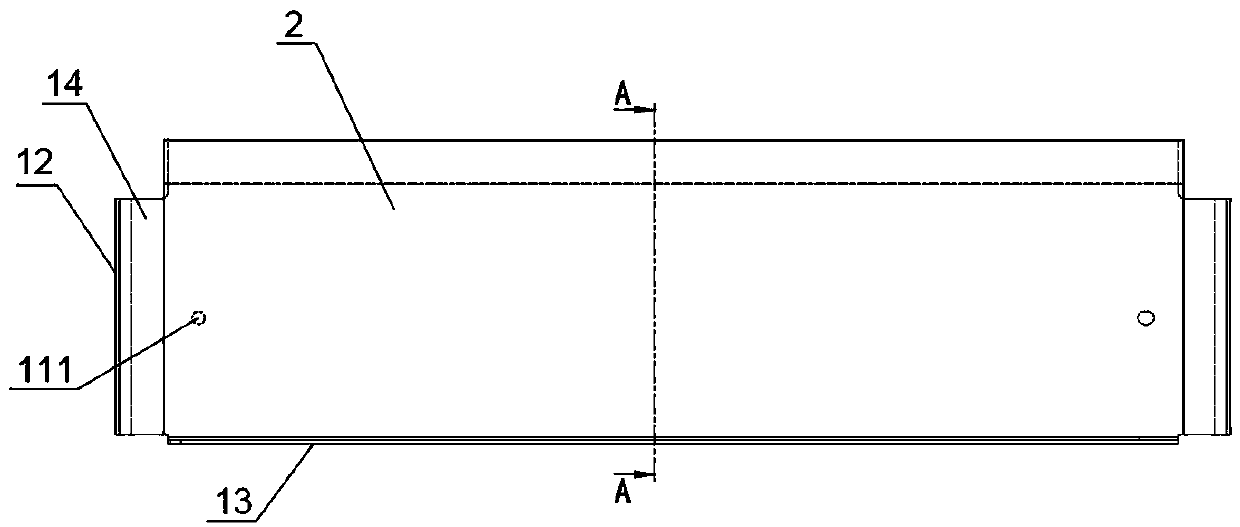

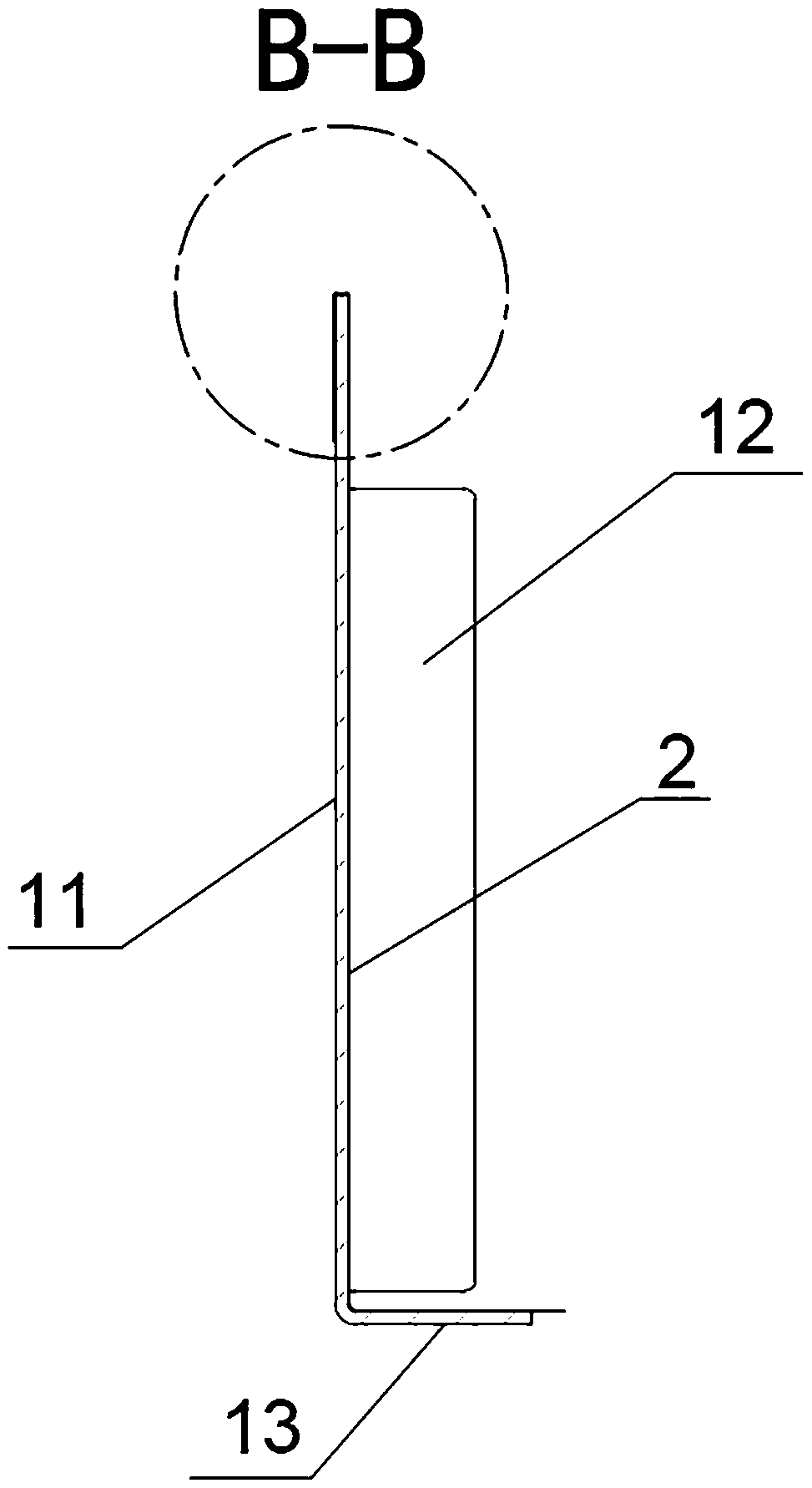

[0031] Such as Figure 1-4 As shown, the present invention includes a board body and an insulating film 2 covered on the side of the board body; The support plate 13 at the lower end of the main plate 11, the limiting plate 12 and the support plate 13 are bent vertically to the same side of the main plate 11; the insulating film 2 covers the upper surface of the support plate 13, and the The side surface of the main body plate 11 connected to the upper surface of the support plate 13, and the two ends of the insulating film 2 are respectively extended to the end of the support plate 13 and the main body plate 11, and on the The ends of the main board 11 are turned over to cover the ends of the main board 11 . An extension plate 14 is provided between the limiting plate 12 and the main body plate 13 . The height of the limiting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com