Crossing method for transmission line tension stringing construction

A transmission line and tension technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of reducing the height of the wire, the wear of the wire surface, the damage of the wire dragging, etc., and achieve the effect of increasing the height, ensuring safety, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. All other embodiments obtained below all belong to the protection scope of the present invention.

[0031] A spanning method for tension setting-out construction of transmission lines, comprising the following steps:

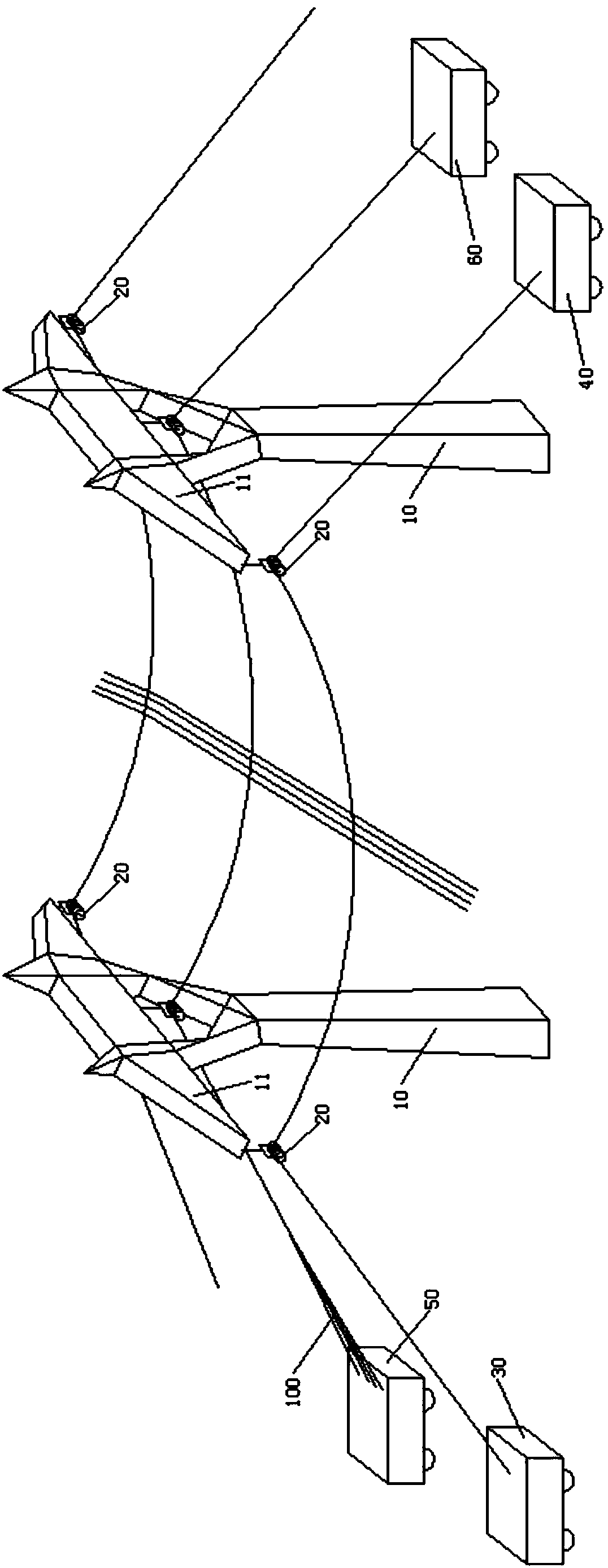

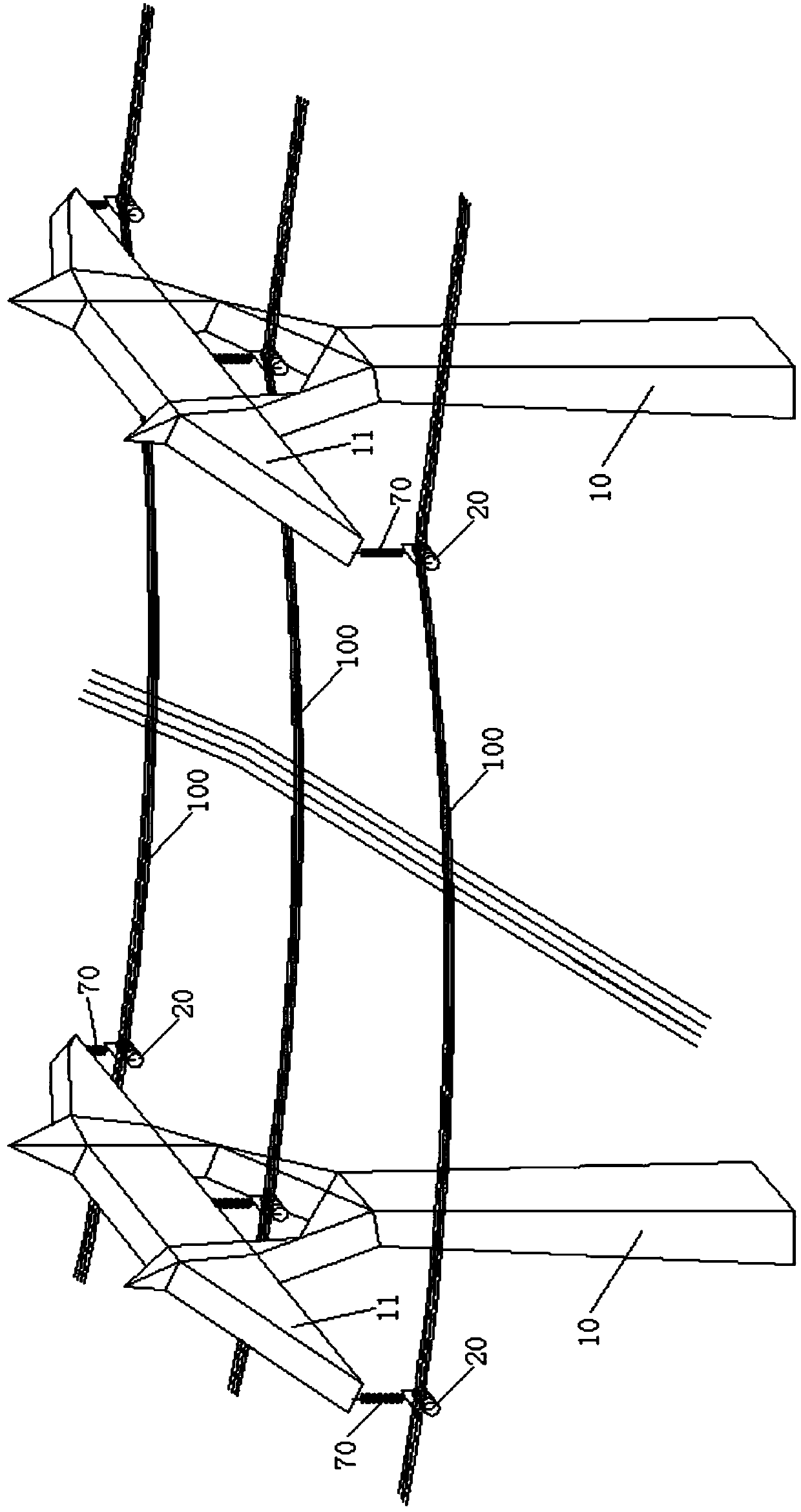

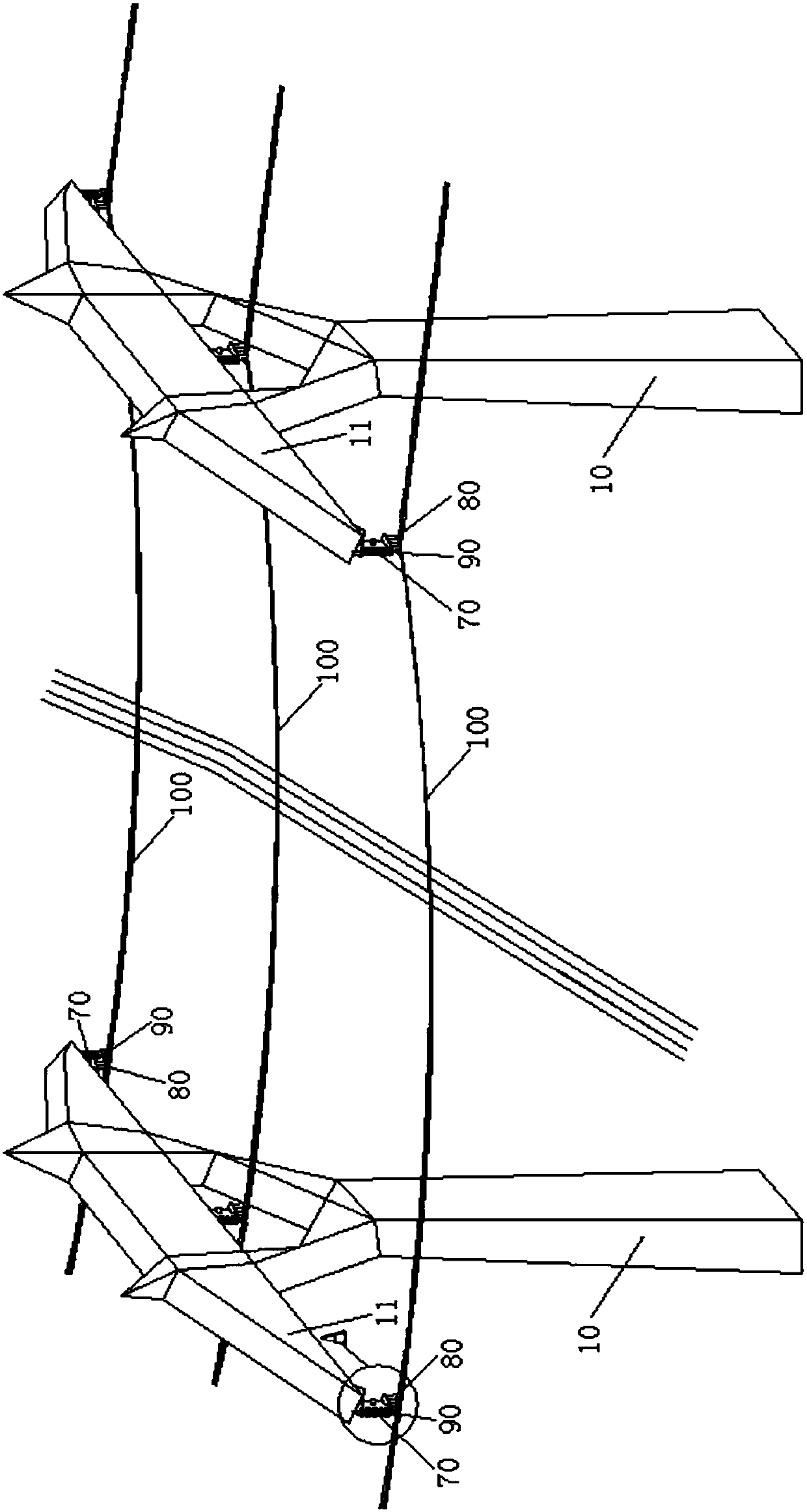

[0032] 1) A cross arm 11 is fixed on the top of the power iron tower 10 where the wire 100 needs to be erected, and a number of pay-off tackles 20 are respectively arranged at the two ends and the center of the cross arm 11, and the pay-off tackle 20 and the cross arm 11 are connected by Metal fittings or 0.5-1 meter long steel rope sets are connected together. In this embodiment, a steel rope sleeve is used to connect the pay-off tackle 20 to the cross arm 11, one end of the steel rope sleeve is connected to the mounting hole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com