Loop heat pipe structure

A loop heat pipe and capillary structure technology, which is used in electrical equipment structural parts, cooling/ventilation/heating renovation, electrical components, etc., can solve the problems of poor heat dissipation, no pipe diameter space, and low density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described based on the preferred embodiments of the accompanying drawings.

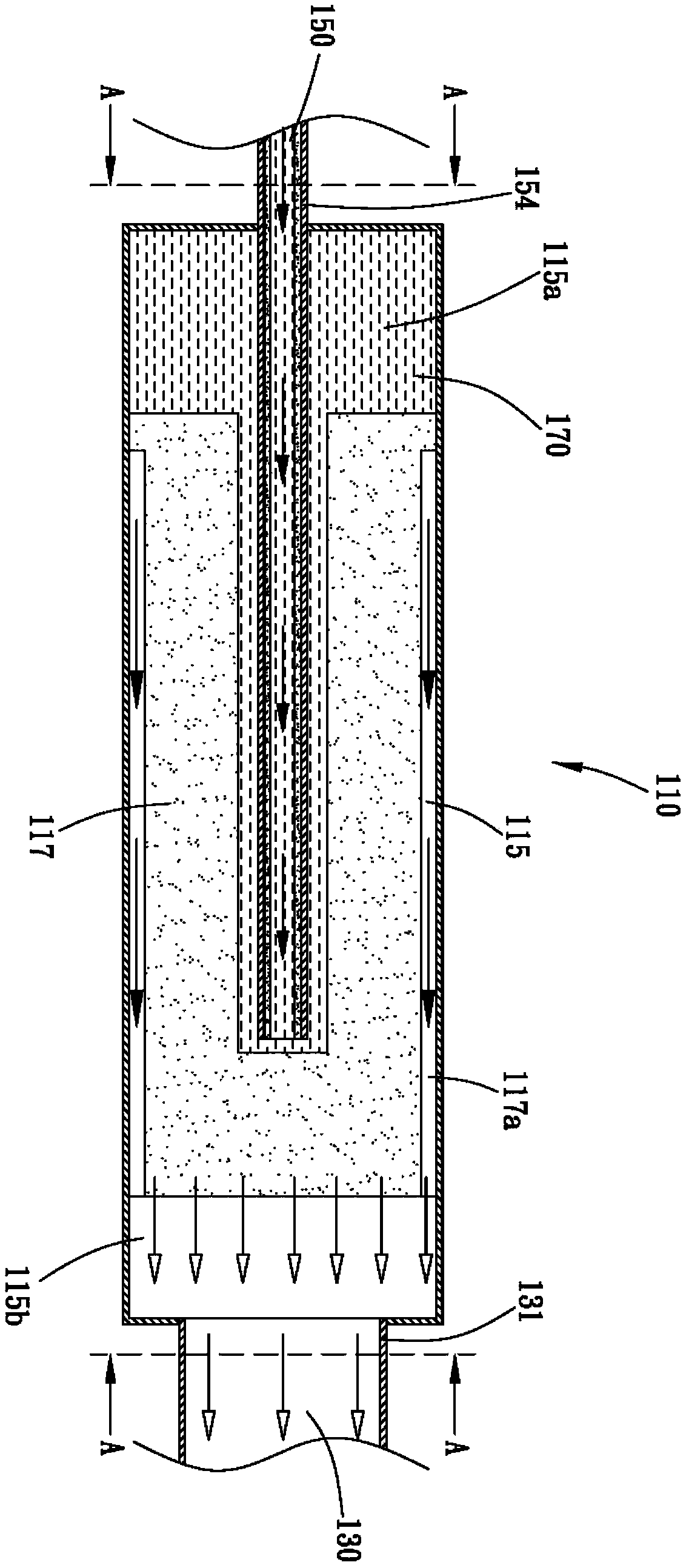

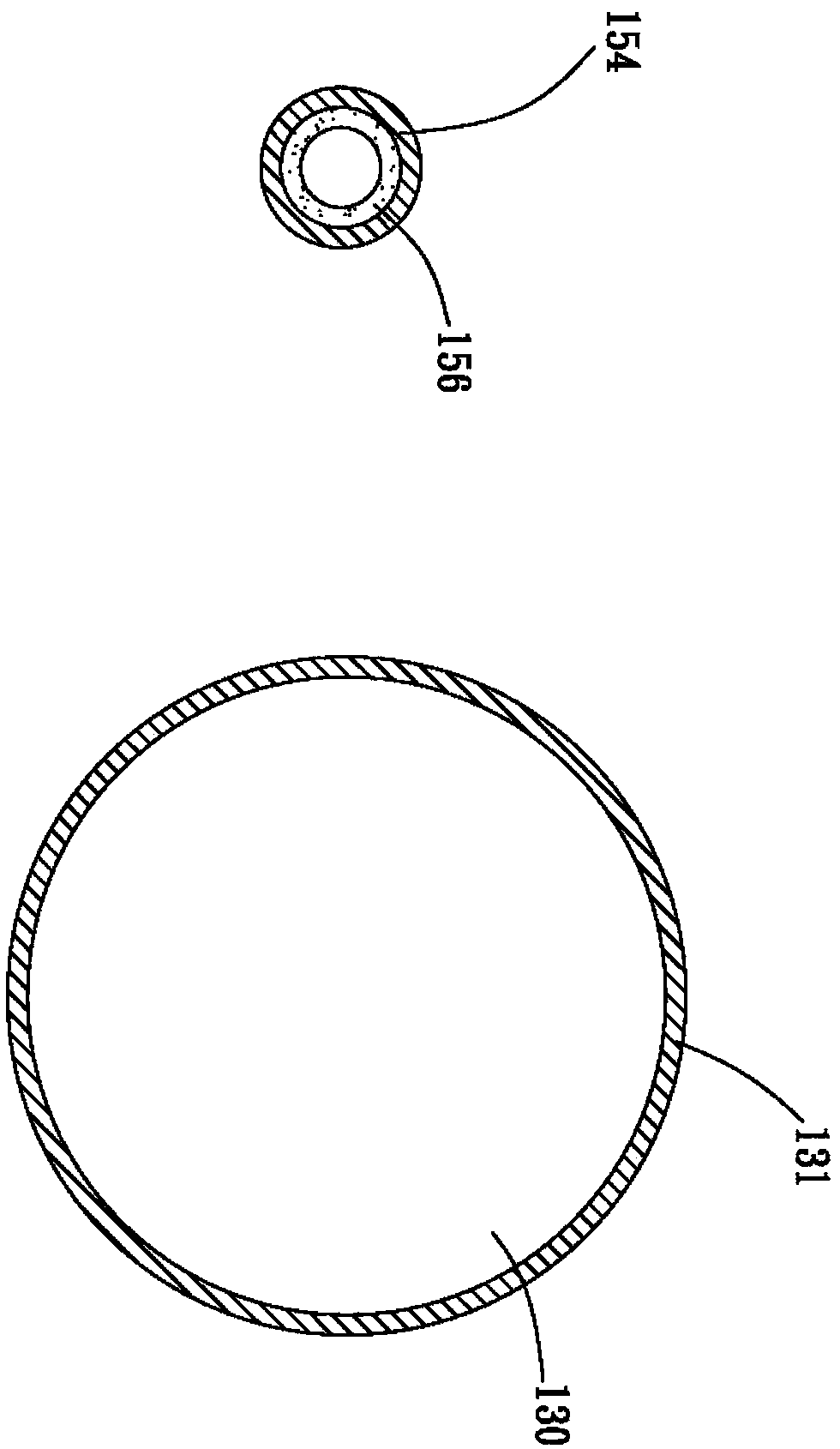

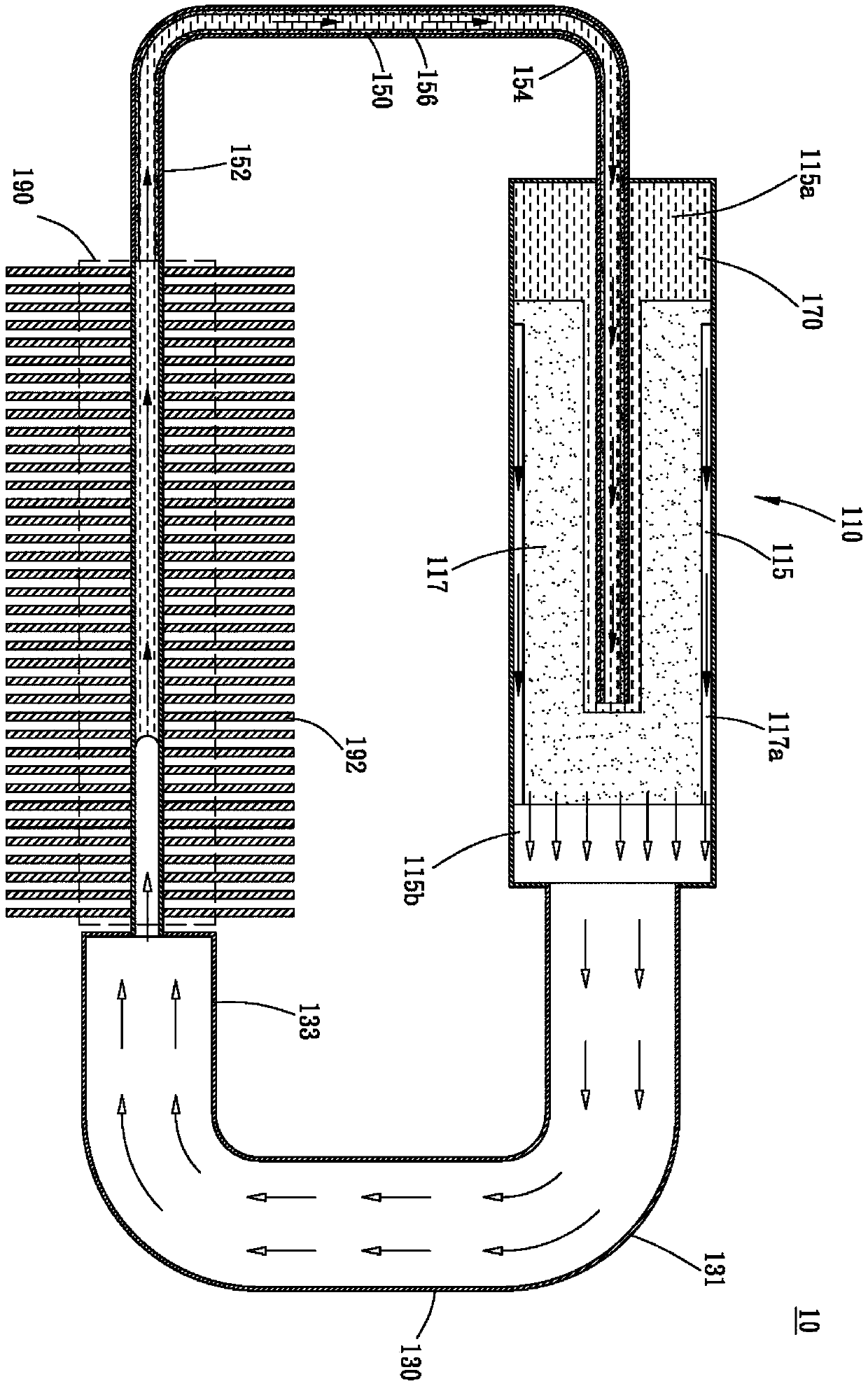

[0050] see figure 1 , 1a and figure 2 , is a schematic diagram of the evaporator of the first embodiment of the loop heat pipe structure of the present invention and a schematic diagram of the total pipe diameter A-A cross-sectional area of a steam pipe and a liquid pipe and a top view sectional view, as shown in the figure, the loop heat pipe of the present invention The structure 10 includes an evaporator 110 , at least one vapor pipe 130 and at least one liquid pipe 150 .

[0051] The evaporator 110 has an evaporating cavity 115 , and the evaporating cavity 115 has a first capillary structure 117 and is filled with a working fluid 170 . In this embodiment, the first capillary structure 117 is shown as dividing and defining the evaporation chamber 115 into a liquid chamber 115a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com